Combined detection method of ultrasonic longitudinal wave reflection method and diffraction time difference method, and TOFD probe applied therein

A time-of-diffraction time-of-flight and joint detection technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and measuring devices, etc., can solve problems such as undetectable defects and difficulties in horizontal position positioning , to achieve the effect of perfect ultrasonic automatic and semi-automatic detection and good detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

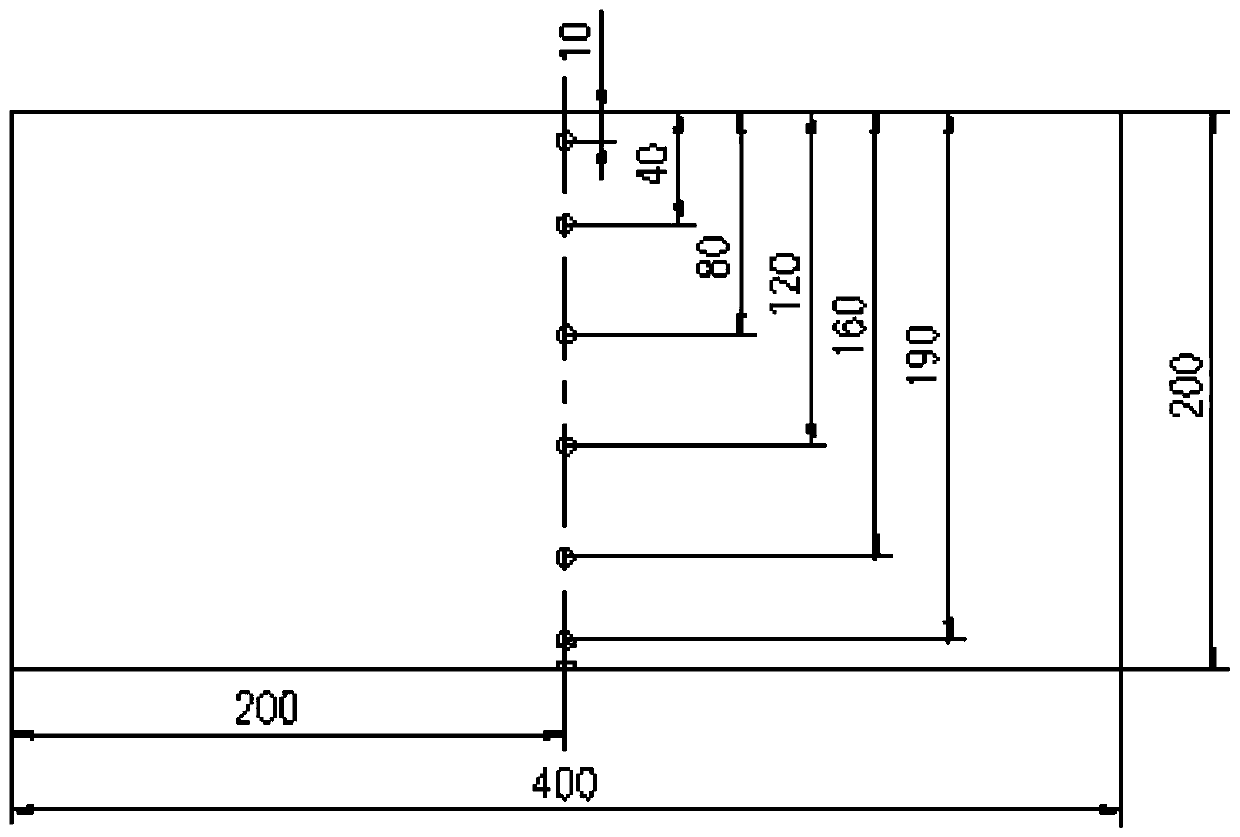

[0173] Verify detection method of the present invention on calibration test block M, wherein, calibration test block M is a rectangle, and its thickness is 200mm, and length is 400mm, and width is 200mm. At the center of the upper surface of the calibration test block M, there are 6 horizontal holes evenly distributed along the thickness direction, and the centers of the 6 horizontal holes are located on the same straight line. The horizontal hole is a cylinder with a diameter of 2mm and a length of 60mm. The axis of the horizontal hole is parallel to the width direction of the calibration test block M, and the distances from the upper surface of the calibration test block M are 10, 40, 80, 120, 160 and 190mm in sequence. There is a rectangular slot directly below the sixth horizontal hole, the slot depth is 2mm, the slot width is 2mm, and the slot length is 60mm.

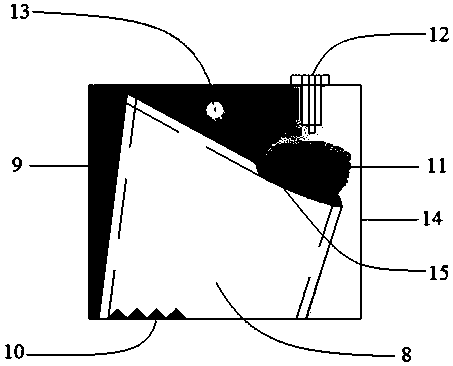

[0174] The probe 7 is a curved TOFD probe, which forms a pair of TOFD probes with the probe 7 on the other side...

Embodiment 2

[0179]For the butt weld with a thickness of 200mm, the method of the present invention is used for detection. The probe and calibration test block adopted in embodiment 2 are the same as in embodiment 1, and the specific operations are as follows: the probe 6 is placed on the calibration test block M described in embodiment 1 , Probe 6 is 15mm away from the center line of the horizontal hole, obtain the reflected echo of the horizontal hole with a depth of 10mm, adjust its wave height to 80% of the full screen height, and use this sensitivity as the reference sensitivity of probe 6. Set the material sound velocity (5920m / s) on the instrument, use the horizontal hole with a depth of 10mm to calibrate the probe delay, and the calibration of probe 6 is completed. Then place the probe 6 on one side of the weld to be tested, 15mm away from the groove of the weld to be tested.

[0180] Place the probe 7 on both sides of the weld to be inspected, and the center distance is calculated...

experiment example 1

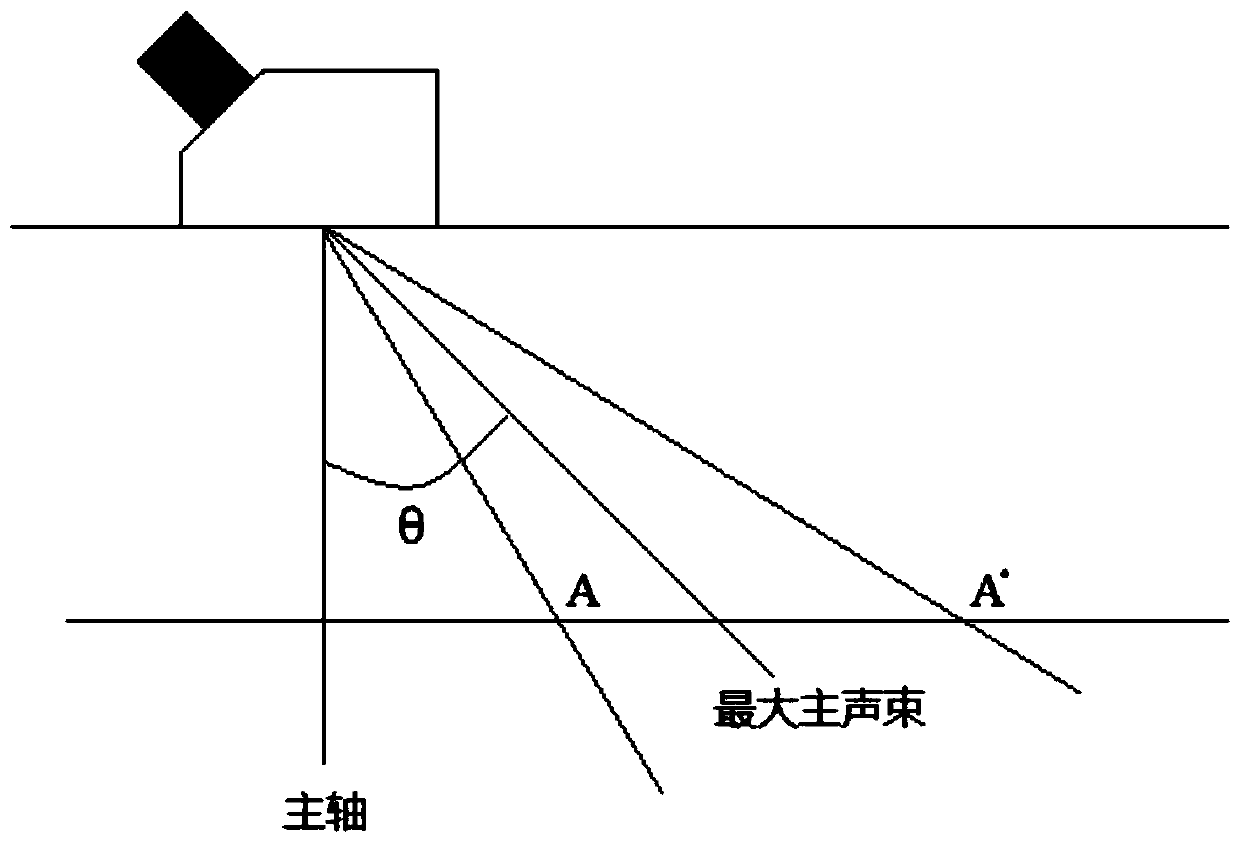

[0195] Experimental Example 1 Probe Diffusion Angle Test

[0196] According to the requirements of NB / T47013.10-2015, the 12dB sound beam spread angle test was carried out. The spread angle test results of the conventional TOFD probe and the TOFD probe in Example 1 are shown in Table 1.

[0197] Table 1 Probe diffusion angle test results

[0198]

[0199] It can be seen from the test results that, under the similar refraction angle, wafer size and frequency, the divergence angle of the curved wafer TOFD probe is much larger than that of the traditional TOFD probe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com