Aging rack system for automatic detection of 3D main controller

A main controller and automatic detection technology, which is applied in the field of aging rack system, can solve the problems of prolonging the production hours of 3D printers, expensive materials, and the inability to test the main controller of 3D printers, so as to avoid the consumption of 3D printing raw materials and reduce power consumption. The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

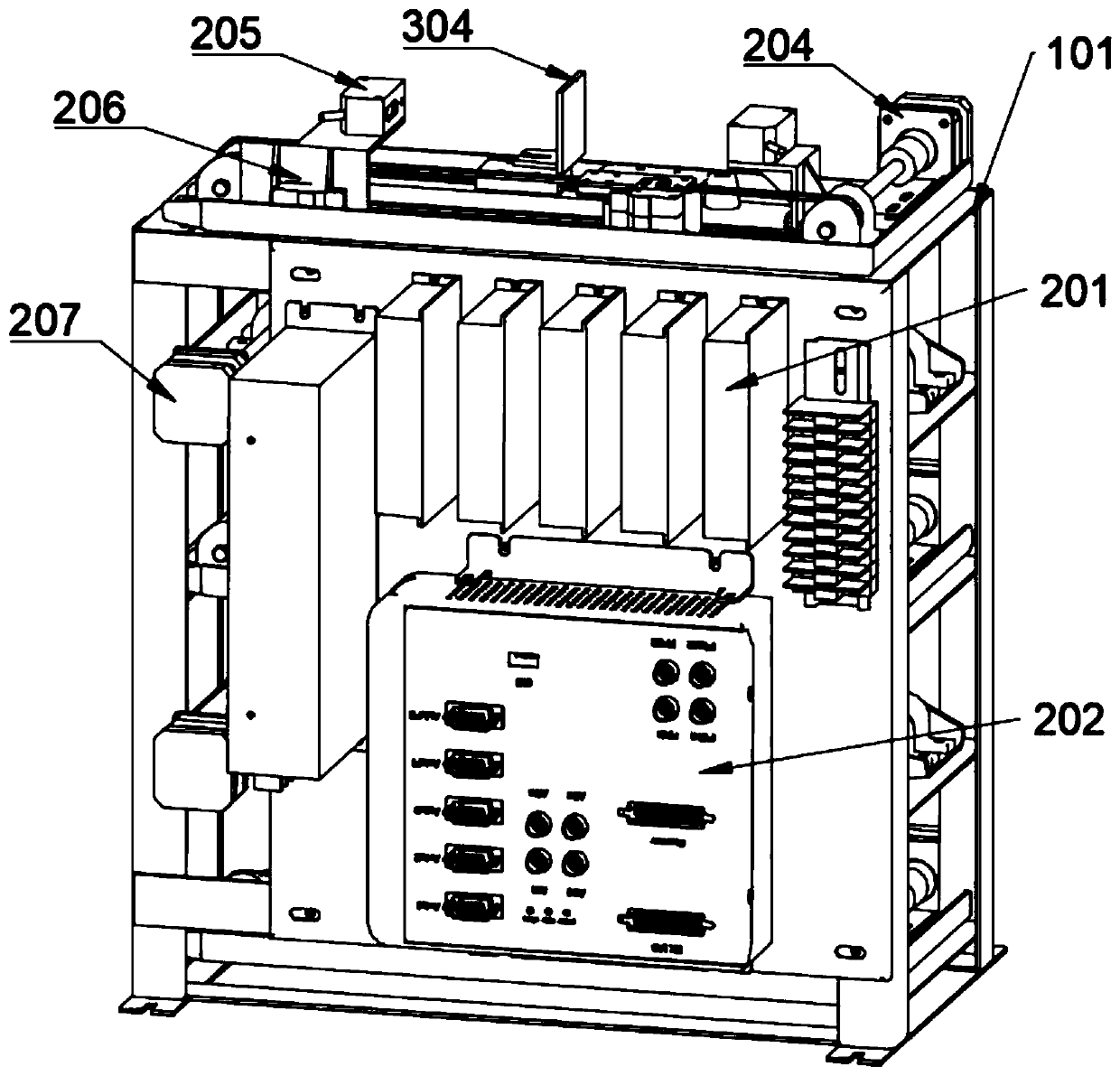

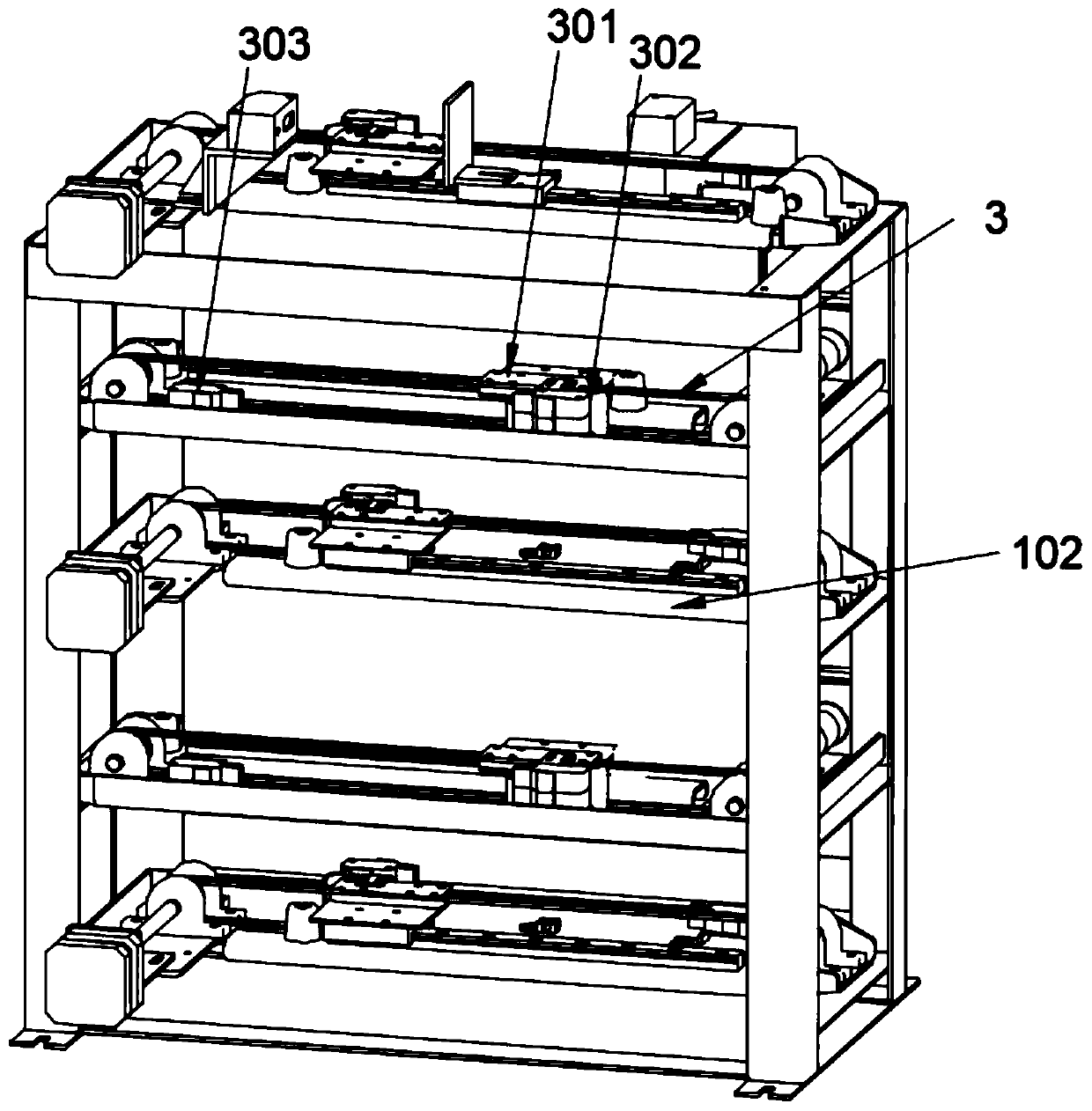

[0020] refer to Figure 1-2 , an aging rack system for automatically detecting a 3D main controller, comprising a fuselage support 101, the main controller 202 is installed on the fuselage support 101, the main controller 202 is provided with a plurality of communication interfaces, and the communication The interface is connected to a monitoring computer (not shown); the body bracket 101 is provided with shaft holders 102 at equal intervals from top to bottom inside it, and the shaft holders 102 are respectively equipped with the first shafts for simulating each axis of the printer. A motion motor 207, the top of the body support 101 is provided with a second motion motor 204, the first motion motor 207 and the second motion motor 207 are driven by the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com