Radioactive gas purification device

A radioactive gas and purification device technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of activated carbon fiber adsorber and high-efficiency filter blockage, shorten the service life of the filter element, and inapplicable purification requirements, etc., and achieve good economic use value, Effect of improving reliability and improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

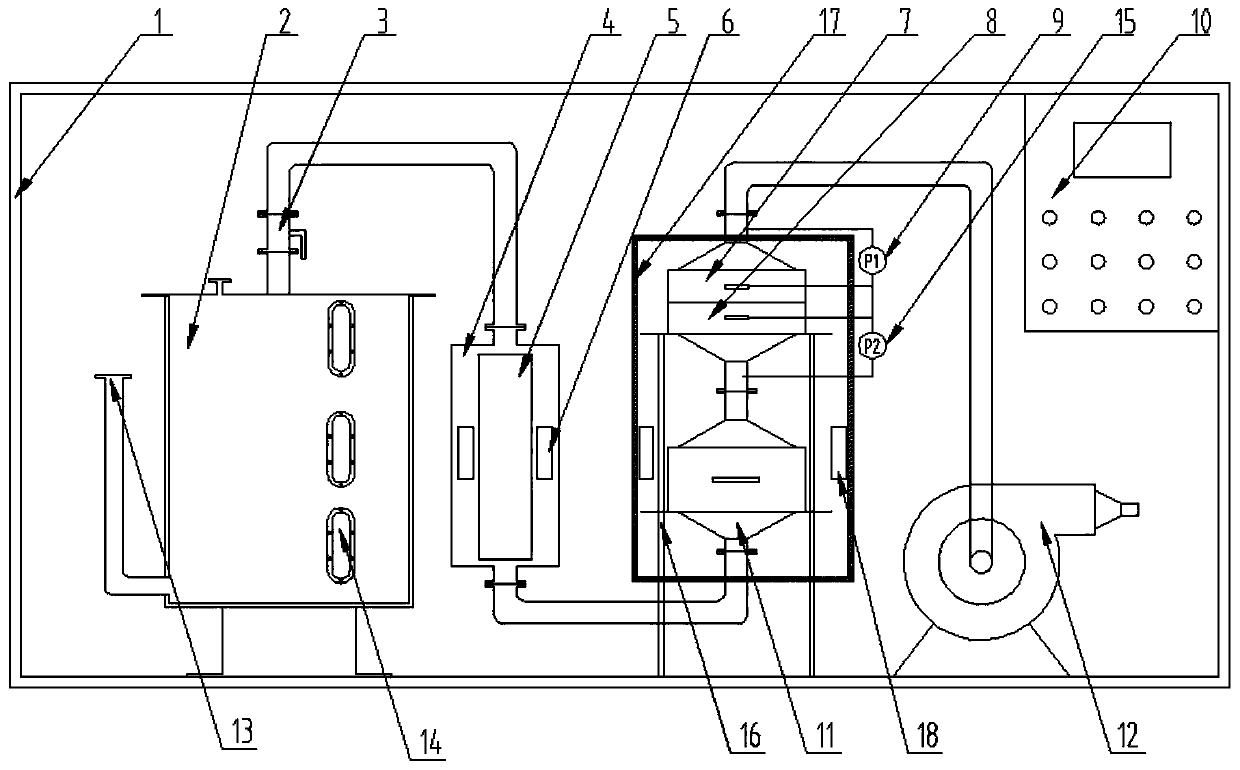

[0019] Attached below figure 1 The present invention will be further described in detail with specific embodiments.

[0020] The purifying device of radioactive gas of the present invention, it comprises filtering device, and filtering device comprises activated carbon fiber adsorber 11, filter, and it also comprises platform 1, primary filtering device, heating and dehumidifying device, control device, and control device adopts PLC controller 10. The primary filter device, heating and dehumidification device, and filter device are connected in sequence and are all carried on the platform 1 by bolts or welding;

[0021] The primary filtration device adopts the filter layer filter 2 to perform preliminary filtration on the aerosol, dust and particles contained in the incoming gas to improve the filtration efficiency;

[0022] The heating and dehumidification device adopts a tubular heat exchanger, which is connected between the filter layer filter 2 and the activated carbon fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com