Two-primary-color low-blue-light white-light LED element and white-light LED component

A dual-color, white technology, applied in the field of white LED components, can solve problems such as reduction, retinal cell fatigue function, lack of emission spectrum, etc., to achieve the effect of reducing function decline, reducing retinal cell fatigue, and good color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

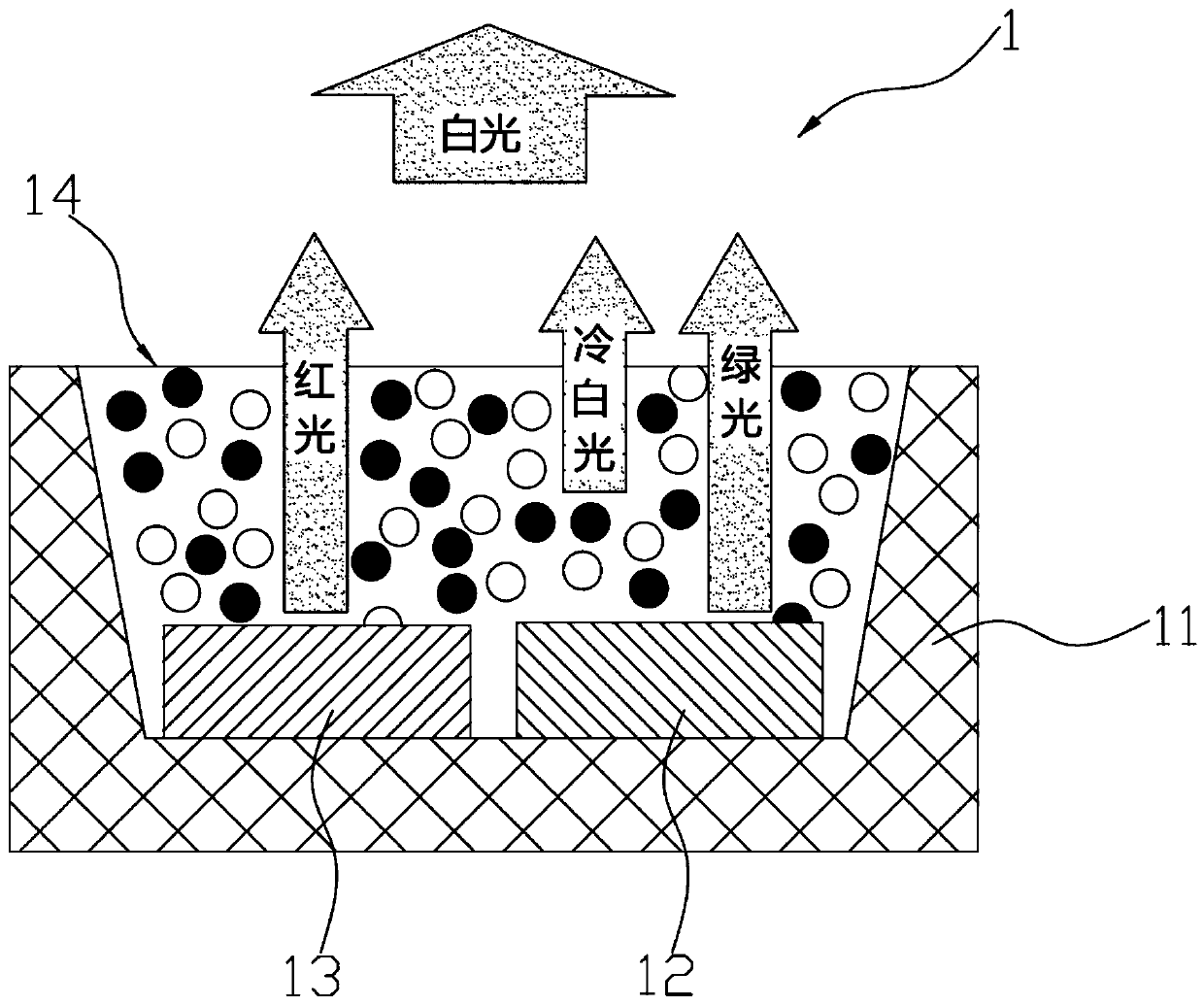

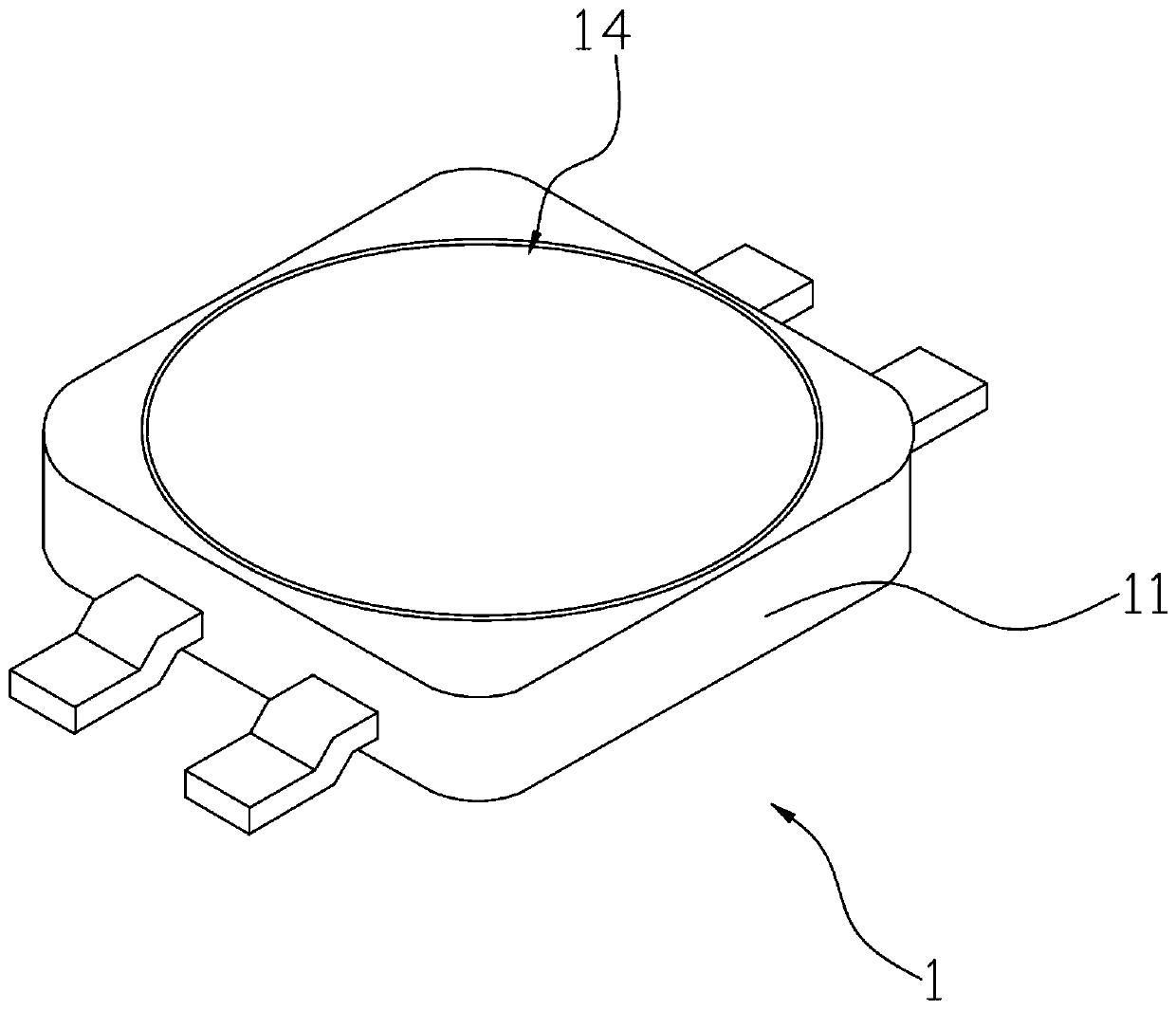

[0022] Such as figure 1 with figure 2 As shown, the first embodiment of the present invention provides a white LED element 1 with dual primary colors and low blue light. It includes a base 11 with a concave cross-section. The bottom surface of the base 11 is fixedly provided with a green-emitting LED 12 and a red-emitting LED. LED13, above the green-emitting LED12 and the red-emitting LED13 is provided an encapsulation coating 14 in the base 11, the encapsulation coating 14 is made of a mixture of cold white phosphor, transparent resin and light diffusing agent;

[0023] The weight percentages of cold white phosphor, transparent resin and light diffusing agent in the encapsulation coating 14 are: cold white phosphor 5-20%, transparent resin 75-90%, light diffusing agent 1-10%;

[0024] The green-emitting LED 12 and the red-emitting LED 13 are respectively connected to different power sources, and the ratio of the current supplied to the green-emitting LED 12 and the current of the ...

Embodiment 2

[0037] Such as Figure 4 As shown, the second embodiment of the present invention also provides a white LED assembly 2 including a plurality of white LED elements 1 as described above and a circuit substrate 21, and the white LED elements 1 are fixed on the circuit substrate 21 at intervals.

[0038] The white LED elements 1 are connected in series, in parallel, or in series and parallel.

[0039] The white LED assembly 2 provided in the second embodiment of the present invention can be used as a lighting fixture by arranging and installing a plurality of white LED elements 1 on the circuit substrate 21. The number and arrangement of the white LED elements 1 can be appropriately designed according to the illuminance and shape (lamp type, fluorescent lamp type) and the like of the required light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com