Welding structure for avoiding Mini LED displacement

A technology of welding structure and displacement, applied in the direction of printed circuits, optics, instruments, etc. connected with non-printed electrical components, can solve problems such as color shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

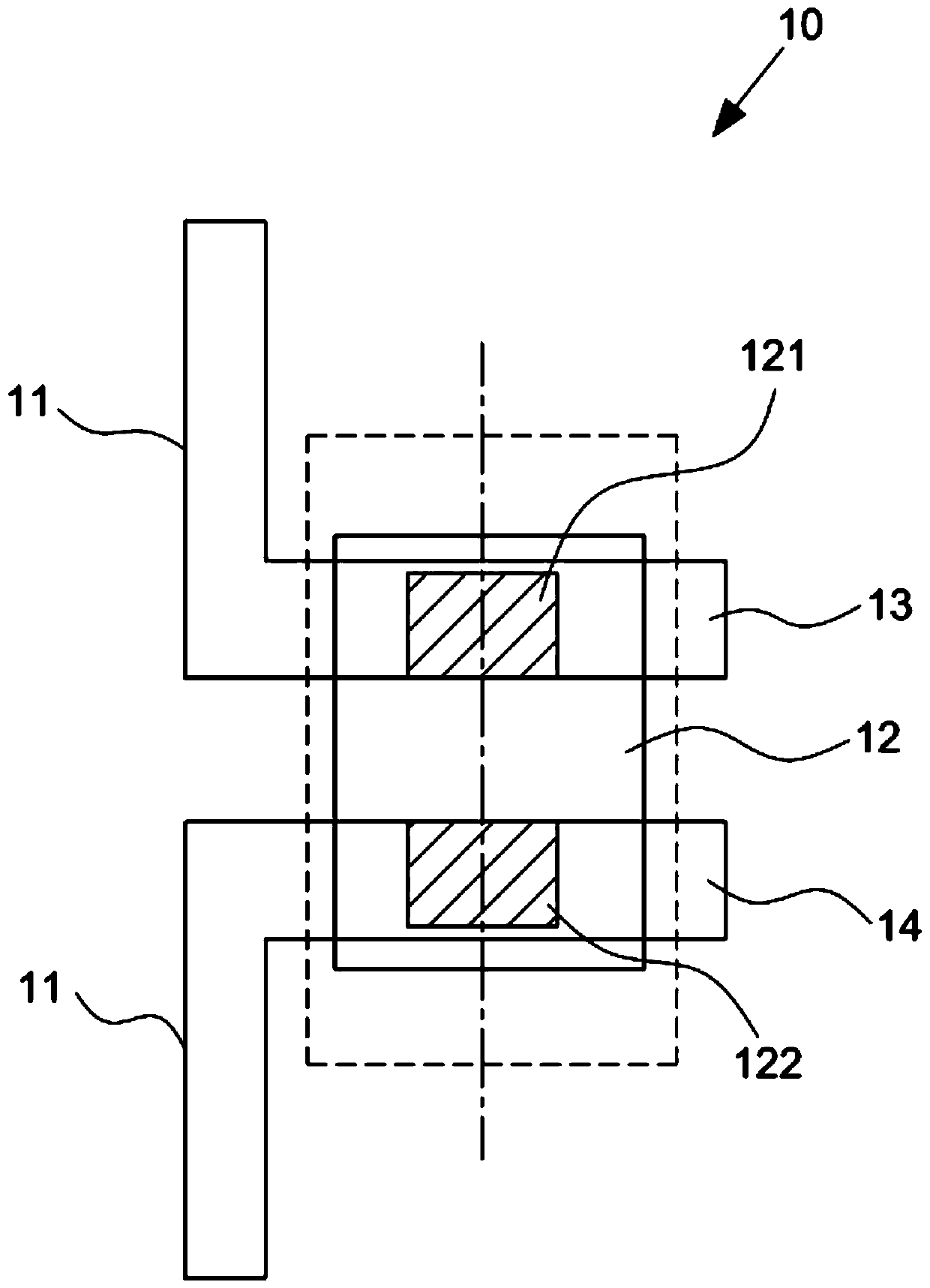

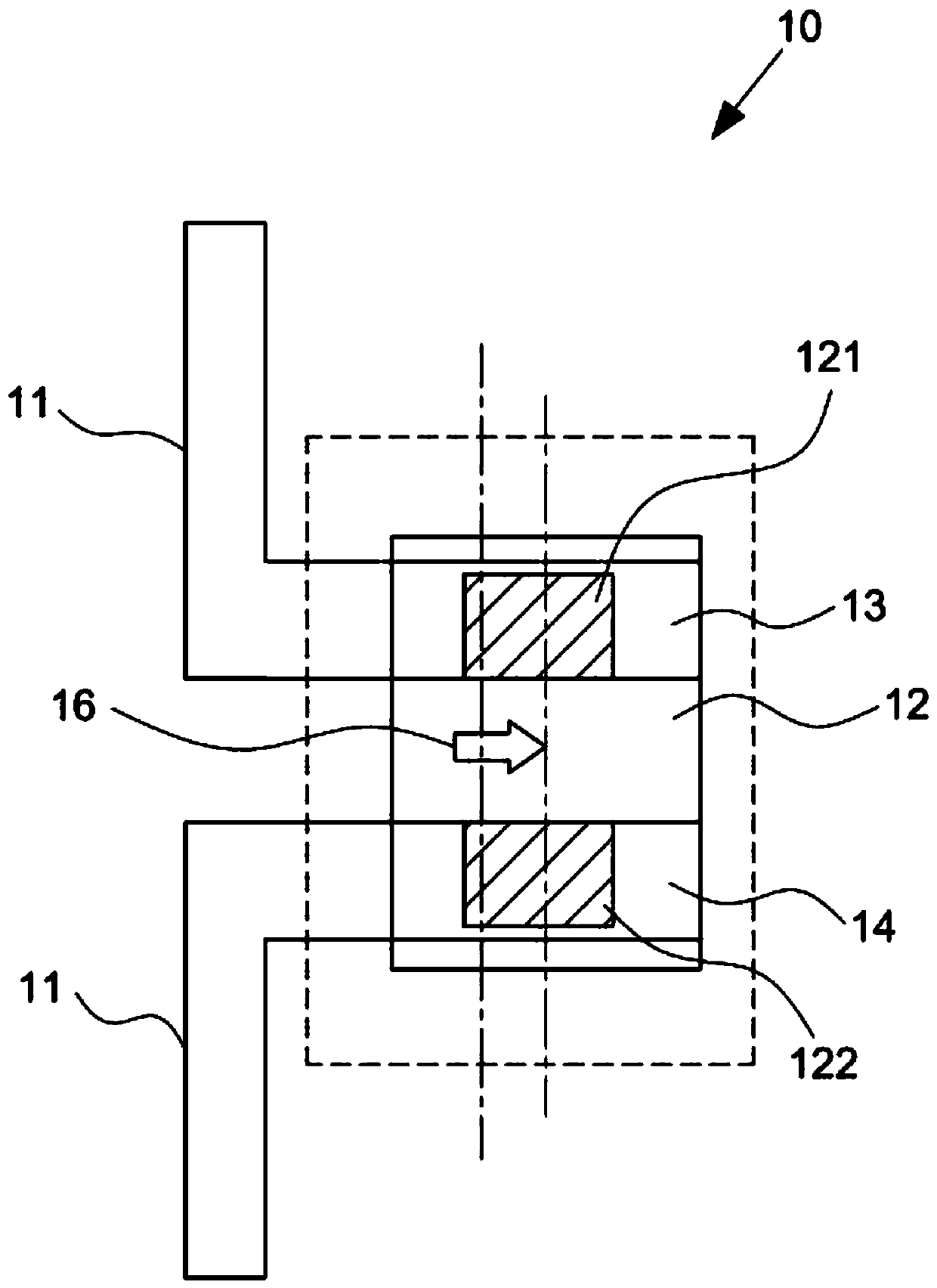

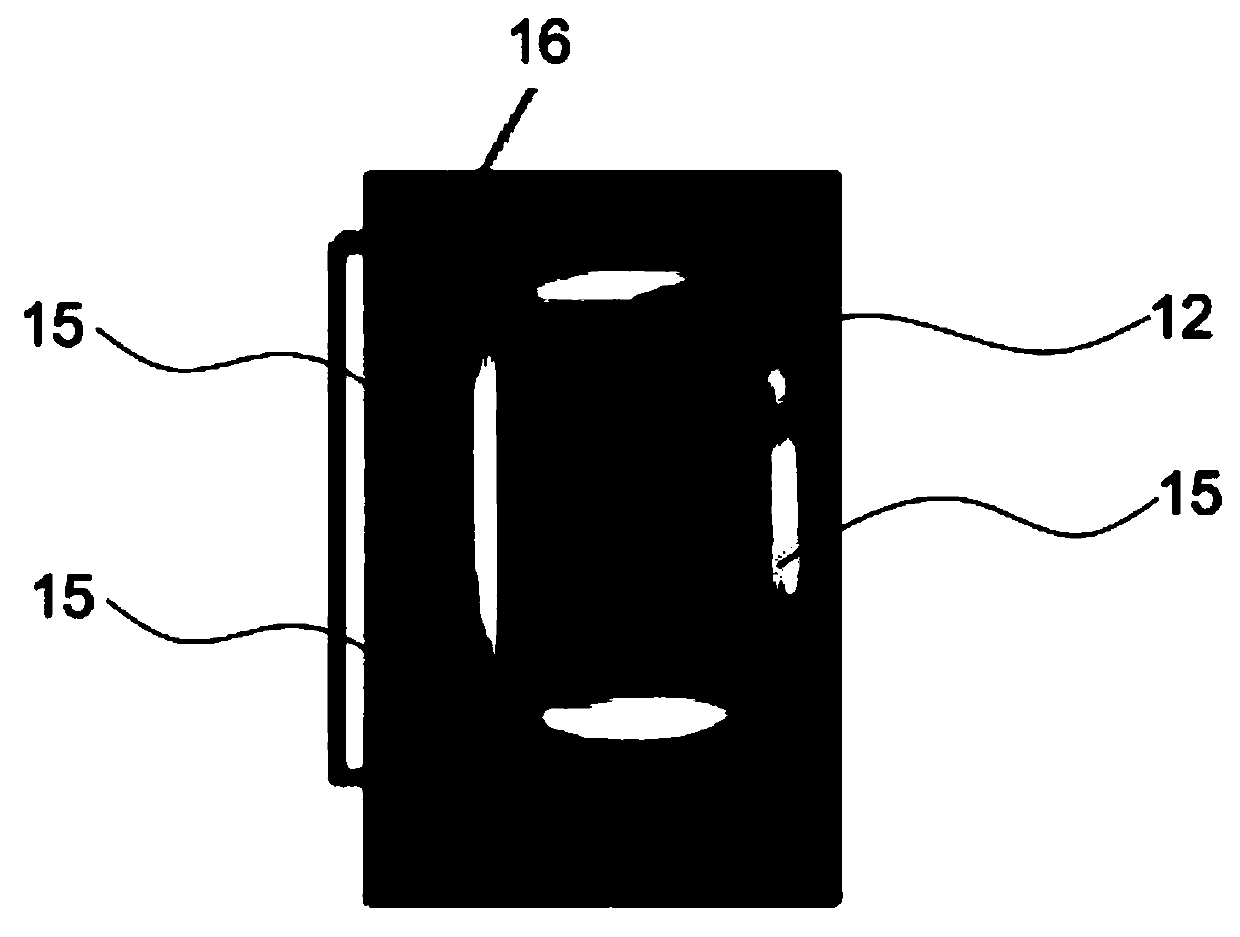

[0022] This invention is about a "welding structure to avoid Mini LED displacement", please refer to image 3 , Figure 4 , Figure 5 As shown, the welding structure for avoiding displacement of the Mini LED in the present invention mainly includes: a pair of metal sheets 30 .

[0023] Wherein, the pair of metal sheets 30 are arranged on the circuit 31 of a circuit board 3 for connecting a Mini LED40, and the pair of metal sheets 30 are located at the two pins 41 and 42 corresponding to the Mini LED40, respectively on the upper and lower sides. Two notches 32 are symmetrically provided to form two welding points for welding the Mini LED 40 .

[0024] With the composition of the above components, when the two pins 41, 42 of the Mini LED40 are soldered to the two soldering points, the two notches 32 of the pair of metal sheets 30 can be positioned and stop the flow of liquid solder, so as to The mutual traction force generated by the surface tension effect of the liquid solde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com