Denitration device for reducing ammonia escape and coal-fired boiler system

A ammonia escape and denitrification technology, applied in the field of coal-fired boilers, can solve problems such as abnormality, safety, economic impact, unsafe boiler equipment load limit, etc., and achieve the effect of preventing ammonia escape and making it easy to pick and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

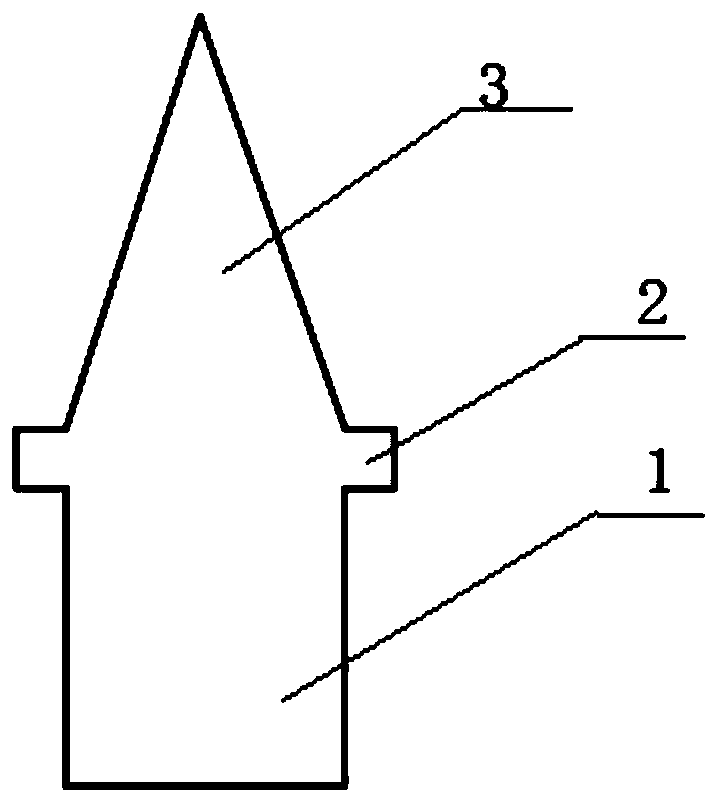

[0034] Such as figure 1 Shown, a kind of denitrification device that reduces ammonia escape of the present embodiment, it comprises:

[0035] A reactor, which is connected with the flue gas channel and the ammonia gas injection device; the reactor is provided with several layers of catalyst compartments, each catalyst compartment is provided with a catalyst, and any two adjacent catalyst compartments are provided with There is a gap between the catalyst compartments, and an ammonia escape structure is installed on the gap between the catalyst compartments; the anti-ammonia escape structure includes a sealing part 1, and the sealing part is used to insert into the gap between the catalyst compartments to seal the gap between the catalyst compartments. The maximum width of the sealing part is equal to the width of the gap between the catalyst compartments, and the length of the sealing part is equal to the length of the gap between the catalyst compartments; both sides of the up...

Embodiment approach

[0039] As an implementation, the ammonia escape prevention structure is a hollow structure.

[0040] Among them, the hollow structure can reduce the weight of the ammonia escape prevention structure and save the manufacturing cost of the ammonia escape prevention structure.

[0041] In this embodiment, the anti-ammonia escape structure is installed on the gap between the catalyst compartments, and the sealing part of the anti-ammonia escape structure is inserted into the gap between the catalyst compartments to seal the gap between the catalyst compartments. At the same time, the protrusion is used to support the sealing part to facilitate the removal of the anti-ammonia escape structure. The guide part at the upper end of the sealing part will also guide the flue gas sent from the flue gas channel into the catalyst compartment, so that the ammonia in the flue gas can react with sulfur trioxide through the action of the catalyst in the compartment to prevent ammonia gas escape...

Embodiment 2

[0052] A kind of coal-fired boiler system of the present embodiment, it is as figure 1 The denitrification unit shown to reduce ammonia slip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com