Fin, stirring shaft and tubular reactor

A tubular reactor and stirring shaft technology, applied in the field of stirring shafts, tubular reactors and fins, can solve the problems of poor heat exchange effect of the reactor, affecting normal reaction production, weak mixing effect of the stirring shaft, etc. Product purity, inhibition of crystal sticking to the wall, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

[0047] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

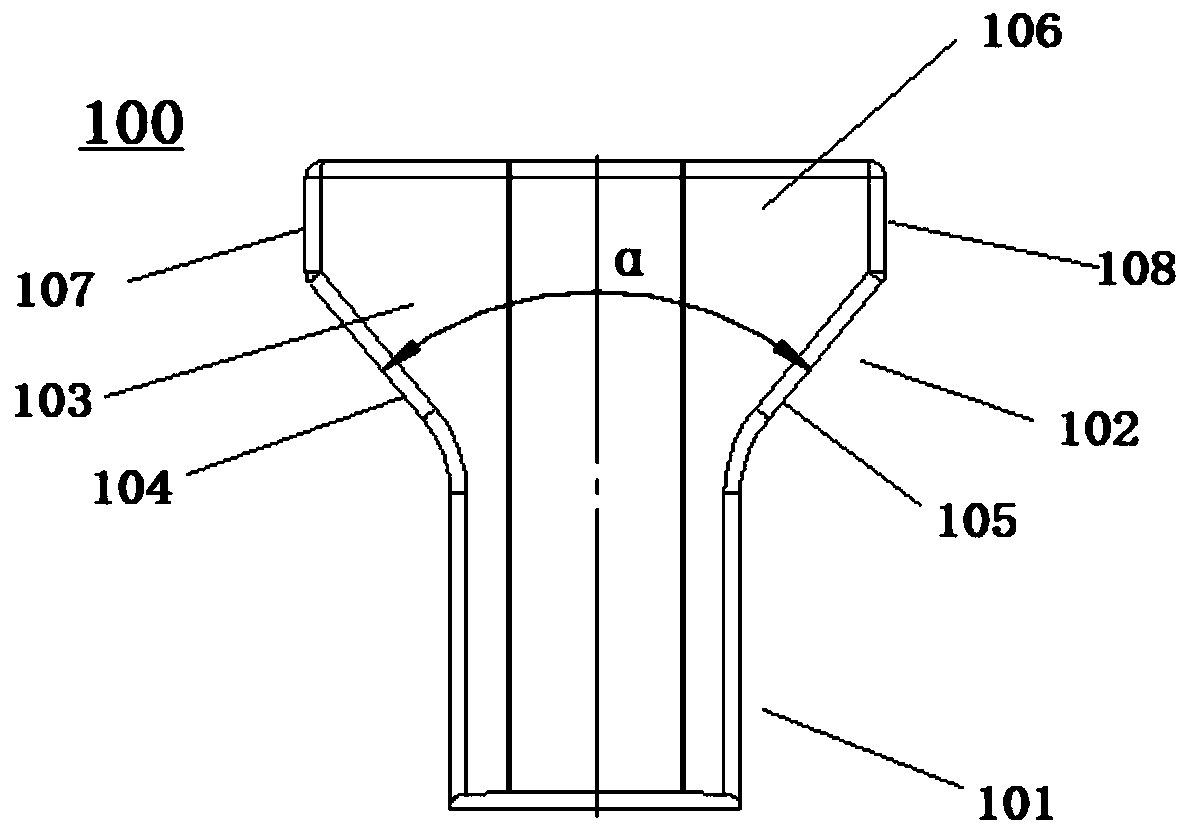

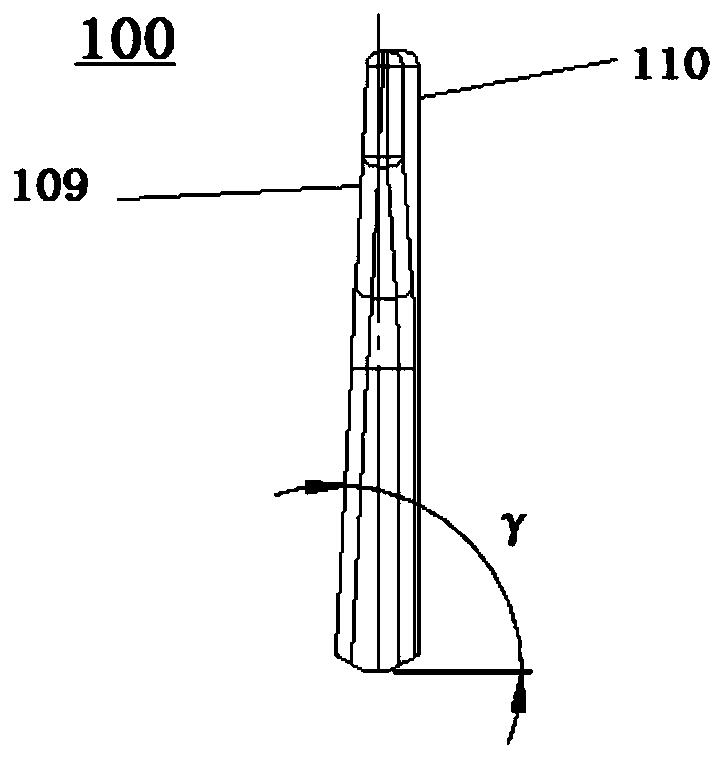

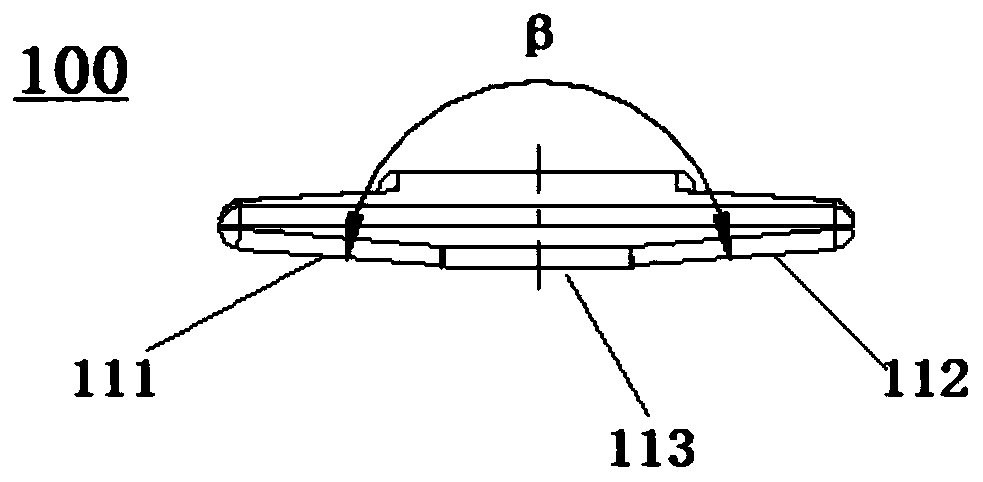

[0048] Such as Figure 1-3 As shown, a fin 100 includes a T-shaped fin body with a liquid-facing surface 110 and a liquid-back surface 109, the T-shaped fin body includes a root 101 and an end 102, and the end 102 includes The expansion part 103 expands to both sides from the junction of the end part 102 and the root part 101 . In this embodiment, the fins are designed as a T-shaped structure, and the T-shaped liquid-facing surface receives a shear area from far to the center due to expansion, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com