Building garbage treatment equipment

A technology for processing equipment and construction waste, applied in grain processing, removing smoke and dust, separating dispersed particles, etc., it can solve the problems of easy generation of dust, human injury, and inconvenient movement of garbage disposal devices, and achieves harm prevention, reasonable structure, and high efficiency. Easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

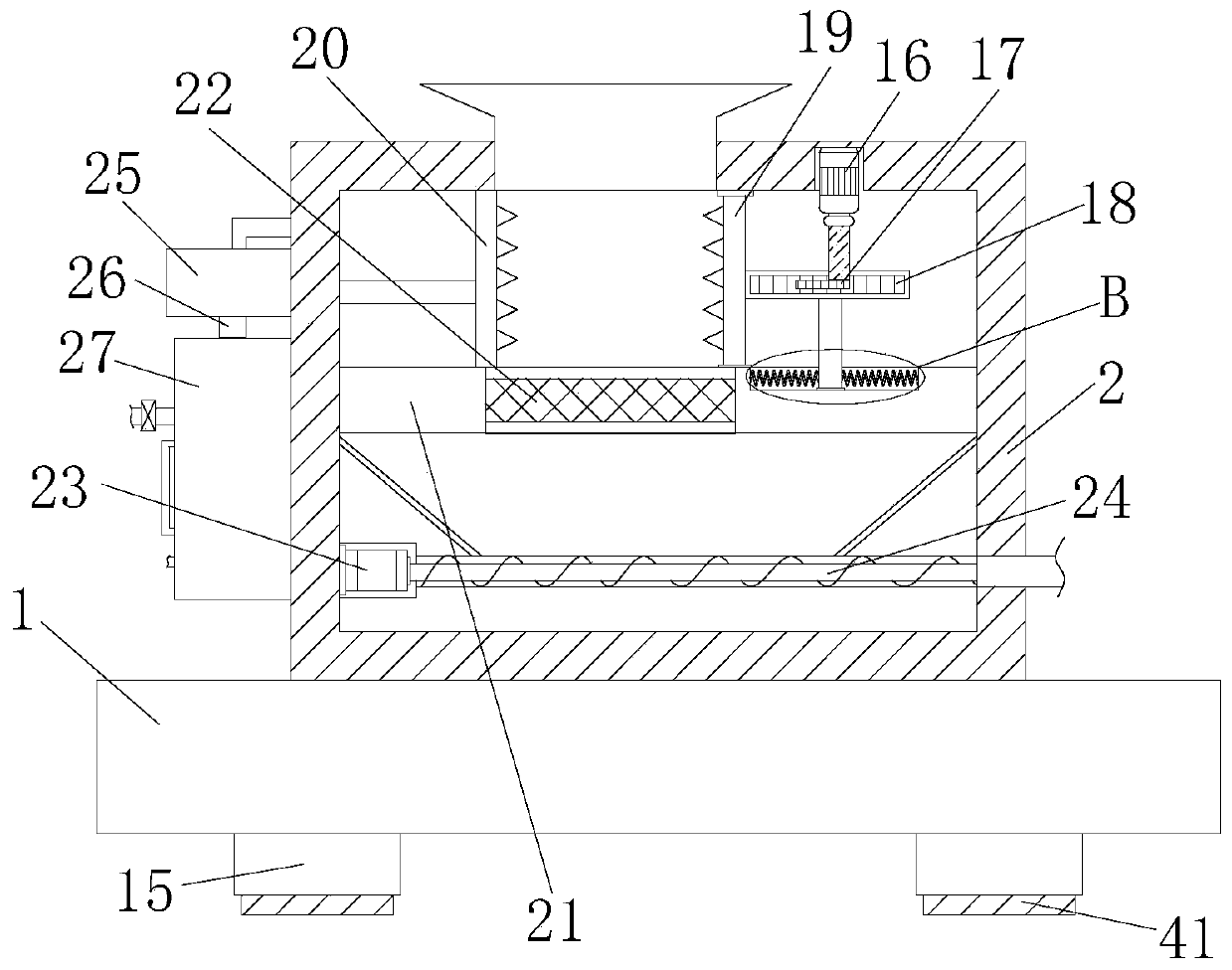

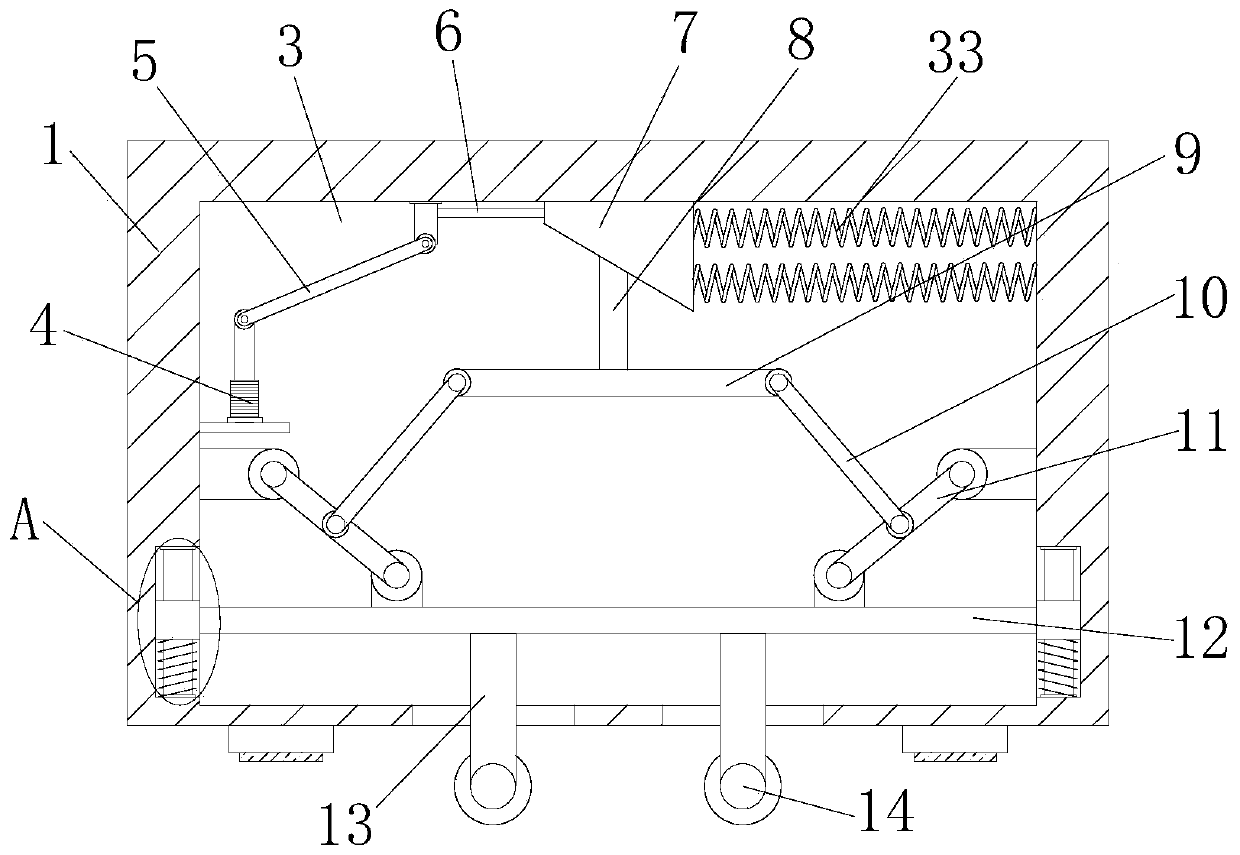

[0026] refer to Figure 1-5In this embodiment, a construction waste treatment device is proposed, including a base 1, a crushing box 2 is fixedly connected to the top of the base 1, a feeding port is provided on the top of the crushing box 2, and an installation chamber 3 is provided on the base 1. An electric push rod 4 is fixedly connected to one side inner wall of the installation chamber 3, and one end of the electric push rod 4 is rotatably connected to a connecting rod 5; Rotately connected with the bottom of the moving plate 6, one side of the moving plate 6 is fixedly connected with a swash plate 7, the top of the swash plate 7 is slidably connected with the top inner wall of the installation chamber 3, and the bottom of the swash plate 7 is slidably connected with a moving rod 8, The bottom end of the moving rod 8 is fixedly connected with a horizontal plate 9, and both sides of the horizontal plate 9 are connected with a first rotating rod 10, and the inner walls of ...

Embodiment 2

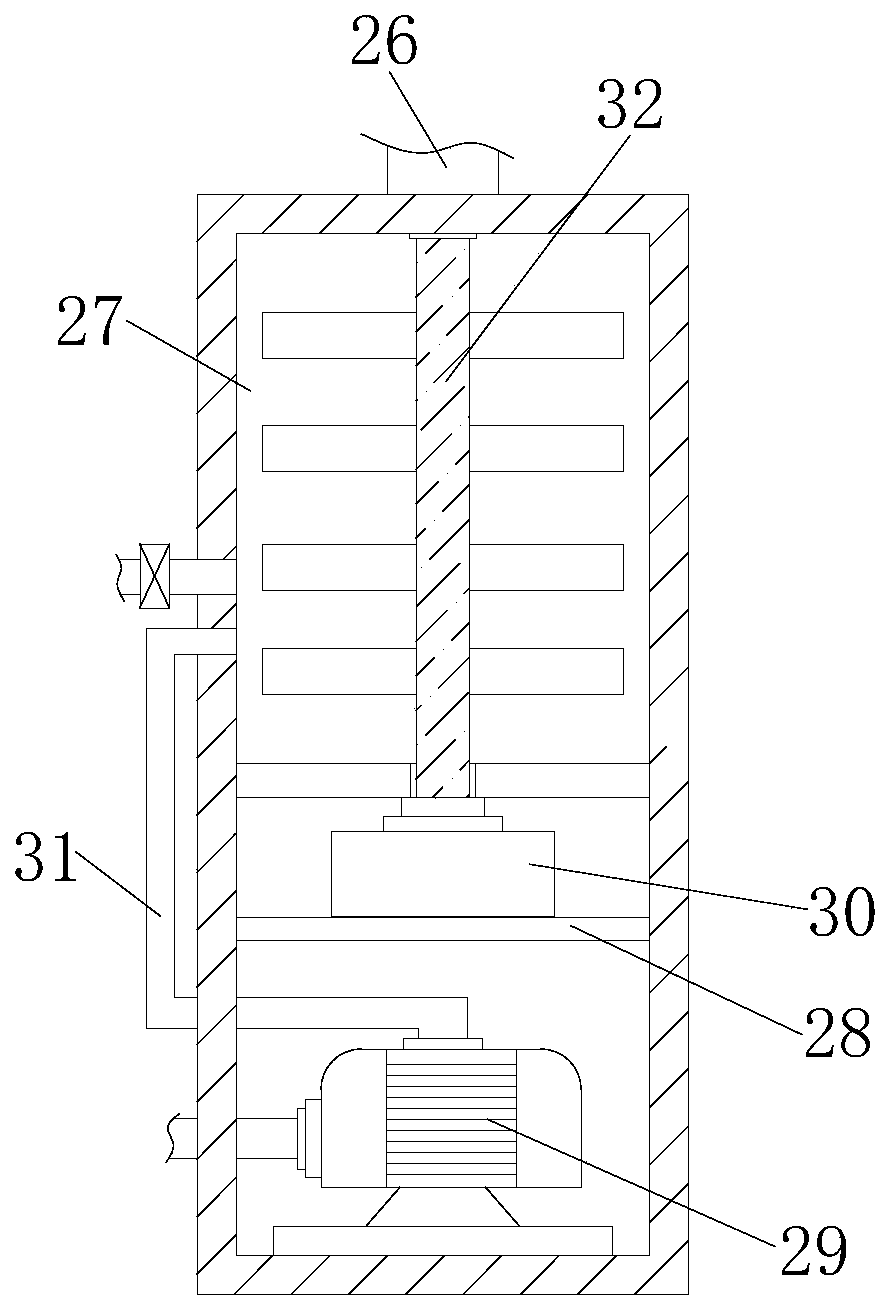

[0028] In this embodiment, the crushing assembly includes a first motor 16 fixedly connected to the inner wall of the top of the crushing box 2, a half gear 17 is fixedly set on the output shaft of the first motor 16, and a rectangular plate 21 is fixedly connected in the crushing box 2. The top of the rectangular plate 21 is slidably connected with a rack 18, the rack 18 is intermittently engaged with the half gear 17, and one side of the rack 18 is fixedly connected with a first crushing plate 19, and the top of the first crushing plate 19 is connected to the top of the crushing box 2. The inner wall is slidingly connected, and the inner wall of one side of the crushing box 2 is fixedly connected with the second crushing plate 20, and the side where the first crushing plate 19 and the second crushing plate 20 are close to each other is provided with crushing teeth, and the top of the rectangular plate 21 is provided with Through holes, filter screens 22 are fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com