Automatic feeding mechanism for tin wire

An automatic feeding and tin wire technology, applied in tin feeding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of no design, etc., and achieve the effects of compact structure, improved production line automation, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

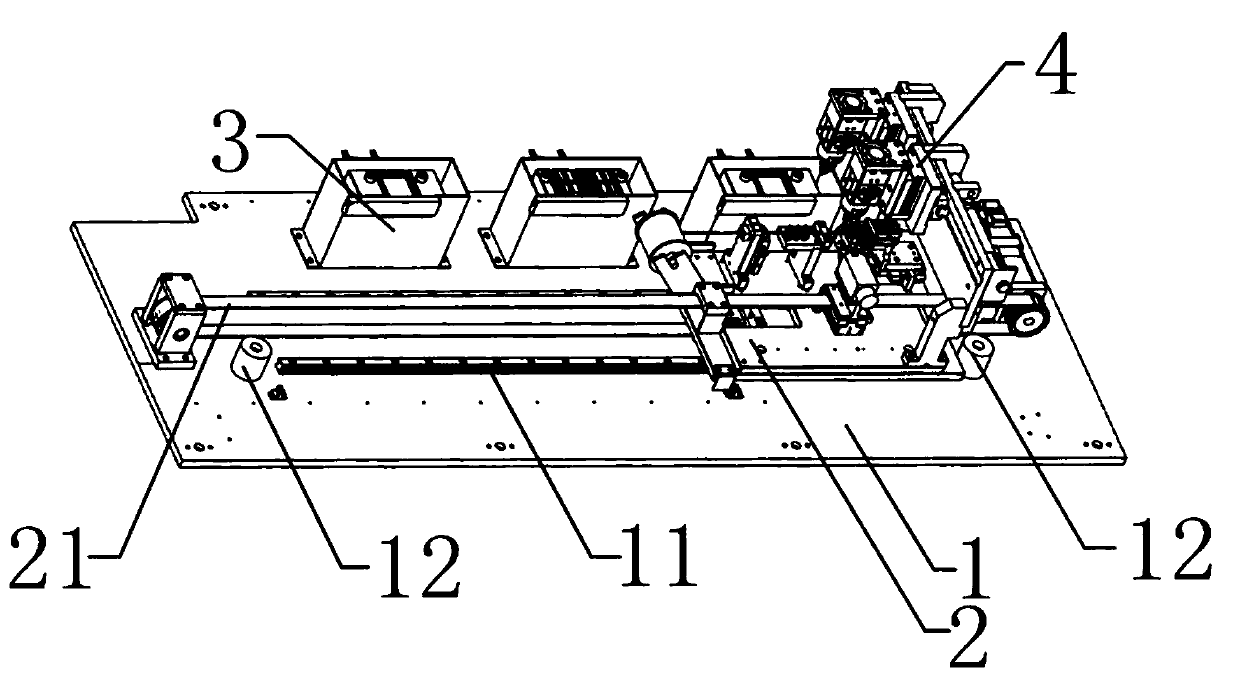

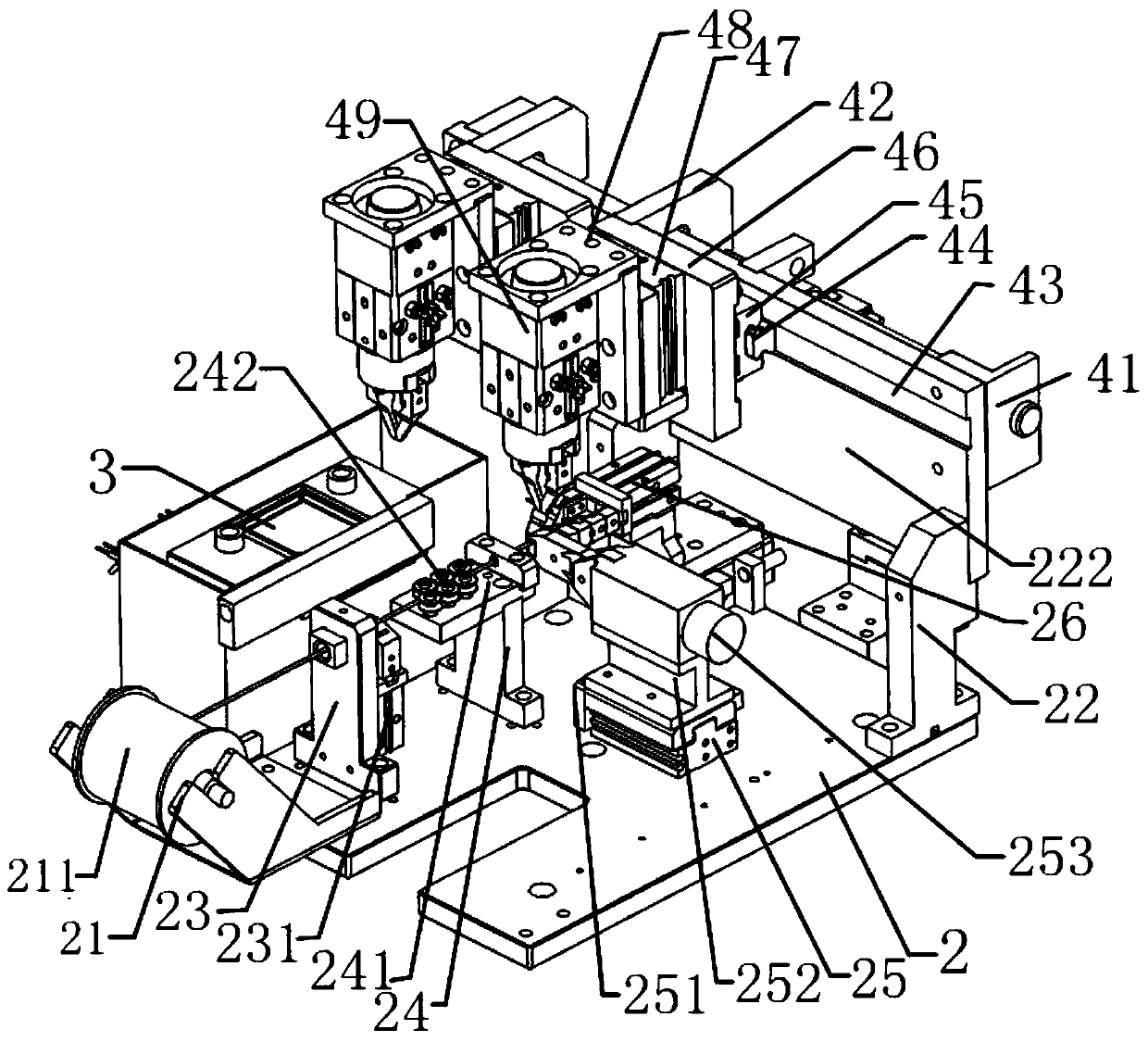

[0019] Such as Figure 1 to Figure 3 As shown, an automatic tin wire feeding mechanism includes a bottom plate 1, a pair of slide rails 11 are fixed on the bottom plate 1 and a sliding seat is fixed, a horizontal moving plate 2 is fixed on the sliding seat, and the horizontal moving plate 2 and the bottom plate 1 are also matched. Belt pulley assembly 21 is arranged, belt clip is fixed on the belt of pulley assembly 21, and the top surface or the bottom surface of belt clip and horizontal moving plate 2 are fixed, and cable tray support 21 is fixed on horizontal moving plate 2 and corresponds to cable tray 211, and cable tray 211 is namely Tools for tin wire winding;

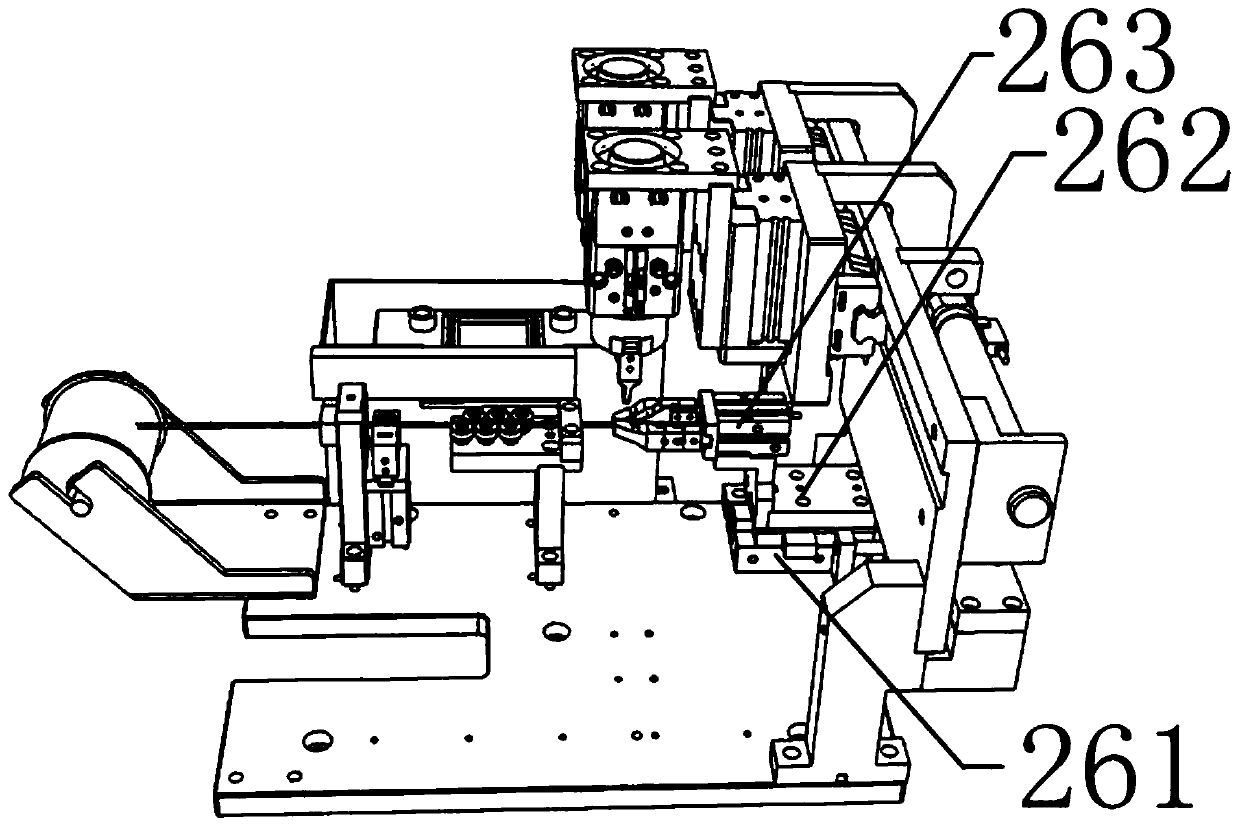

[0020] Wire reel support 21 side is provided with routing mechanism, and this routing mechanism comprises ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap