Laser printing device

A printing device, laser laser technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of reduced product production efficiency, low equipment utilization, low laser printing efficiency, etc., to improve utilization, reduce The effect of the time the device waits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

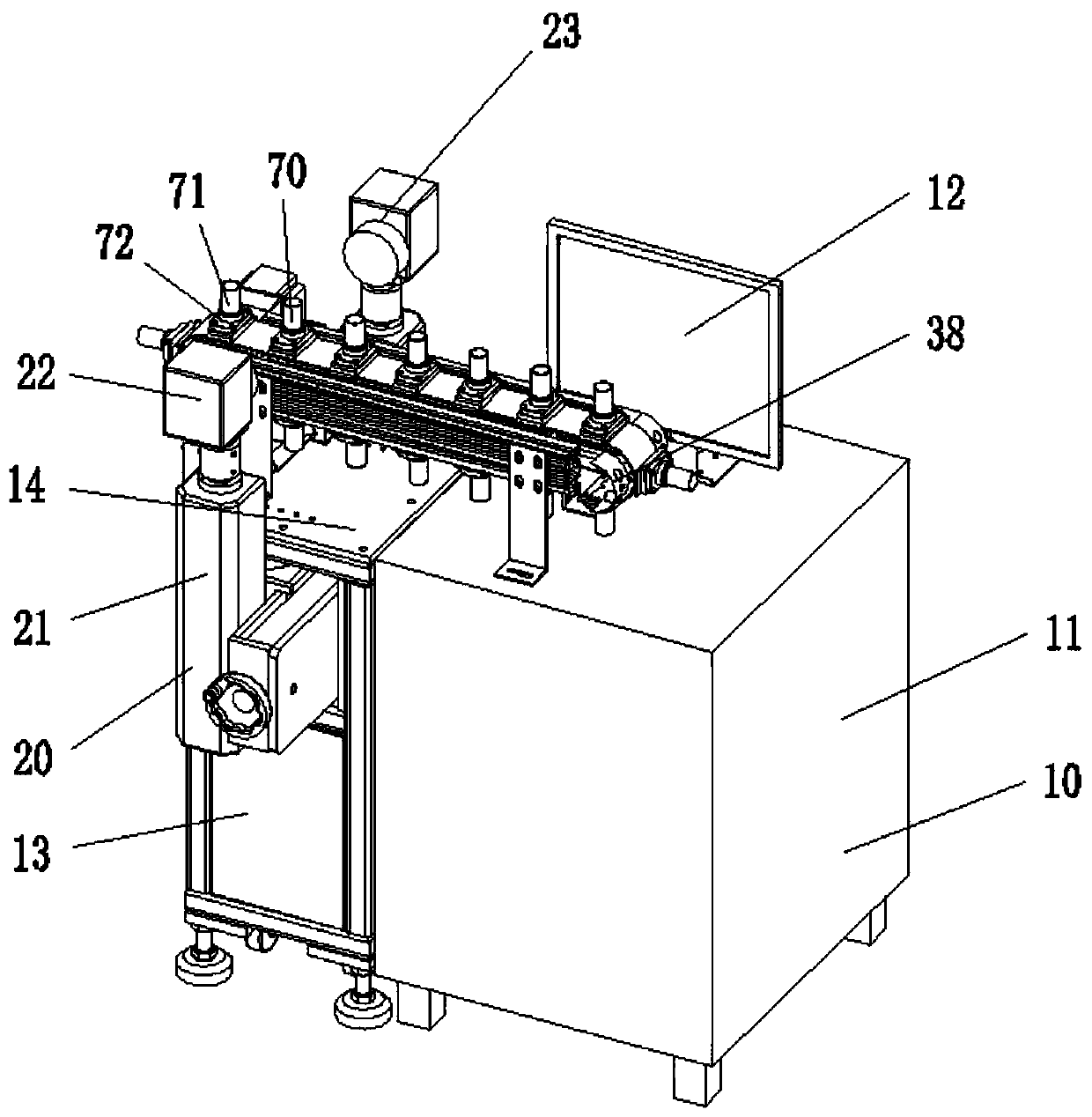

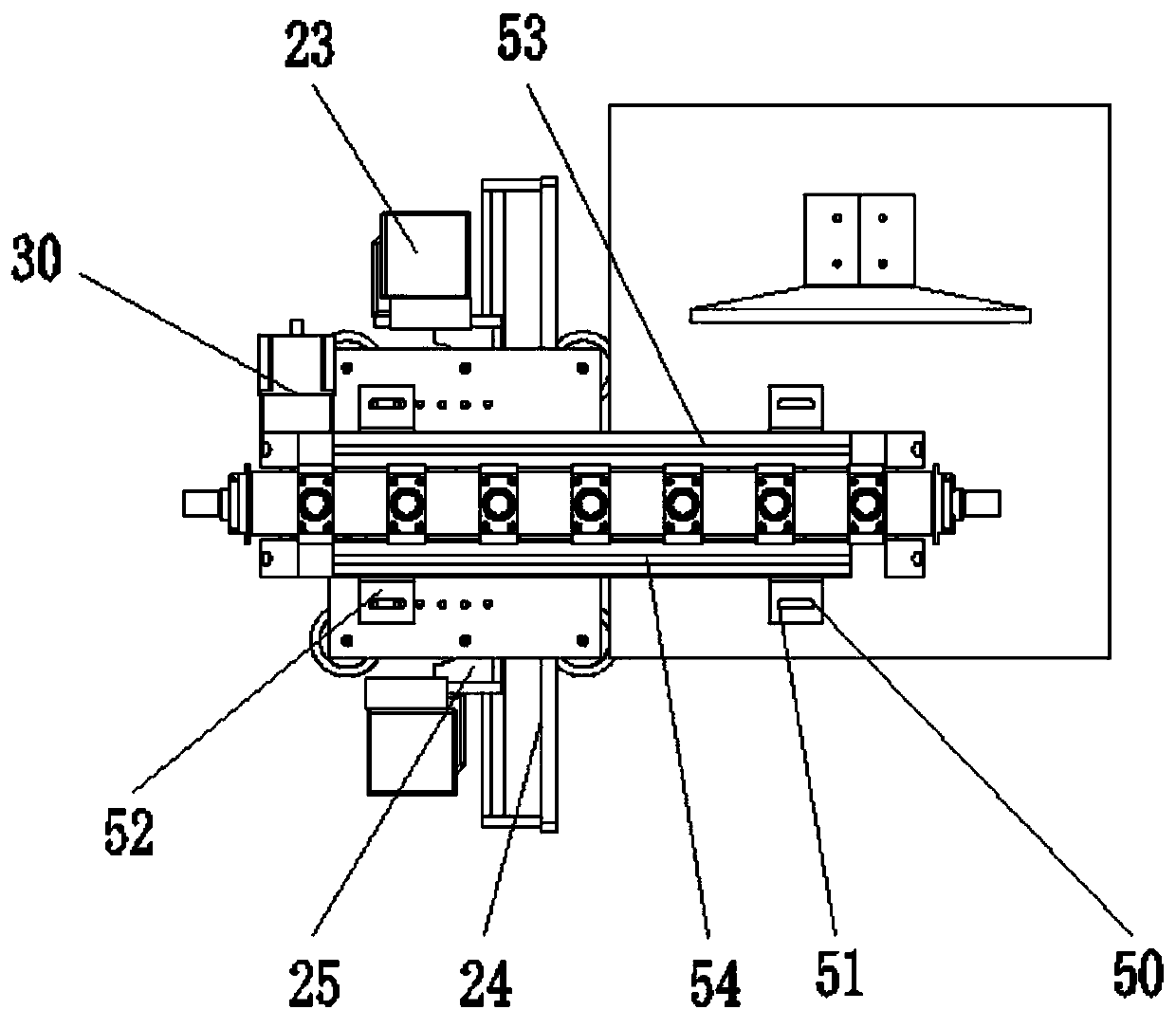

[0027] see Figure 1-5 , the present invention provides a technical solution: a laser laser printing device, comprising:

[0028] The main body assembly 10, the main body assembly 10 includes a first housing 11, a computer 12, a second housing 13, a plate body 14, a through groove 15 and a support assembly 40;

[0029] The printing assembly 20, the printing assembly 20 includes a fixed rod 21, a first laser 22, a second laser 23, a connecting piece 24 and a connecting plate 25, and both sides of the second housing 13 are provided with a fixed rod 21, and the two fixed rods 21 A first laser 22 and a second laser 23 are respectively installed on the top;

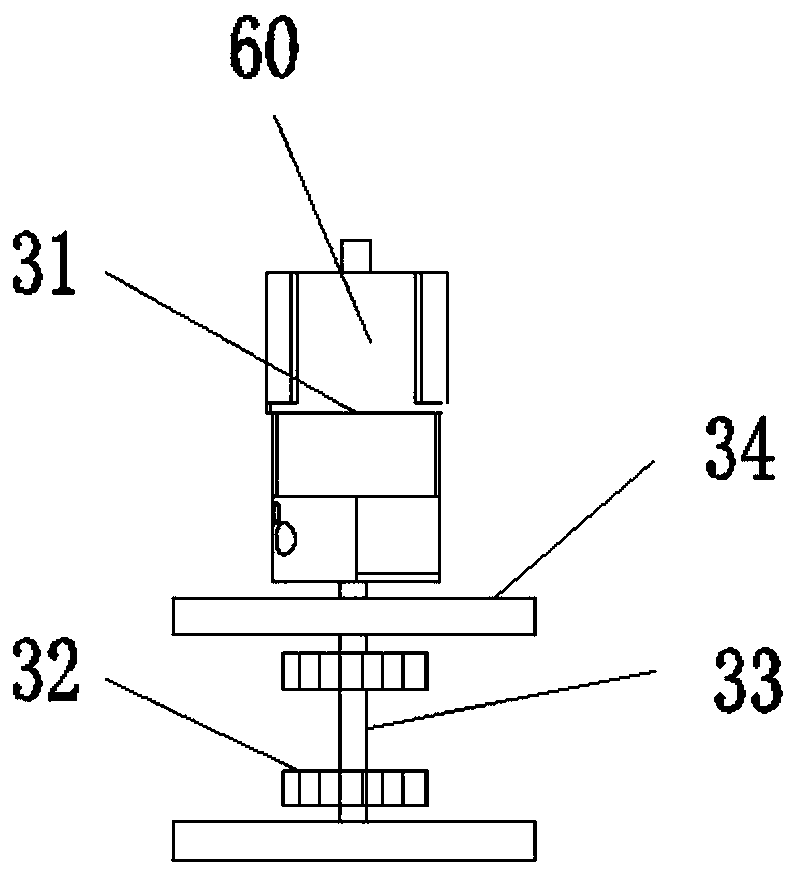

[0030] Drive assembly 30, drive assembly 30 comprises stepper motor 31, gear 32, rotating shaft 33, fixed plate 34, bearing 36, chain conveyer belt 37, conveyer frame 38 fixed assembly 50 and feeding assembly 70, one of the first housing 11 The side screw is connected with a stepper motor 31, and the two sides of the transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com