Full-automatic assembly machine for bolts and assembly method thereof

A fully automatic and assembly machine technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unscientific identification, low assembly efficiency, and errors in manual rotation force, so as to reduce the work of manual classification, High assembly efficiency and effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

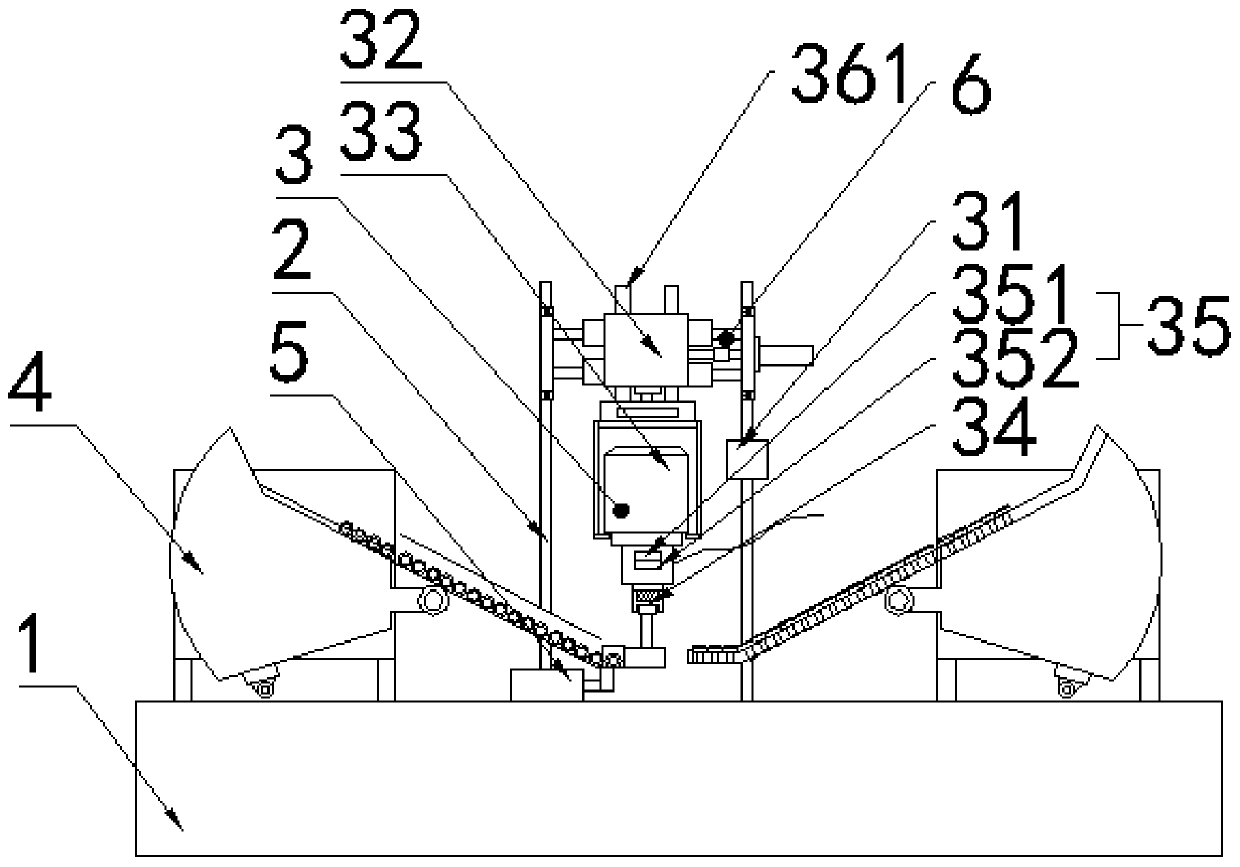

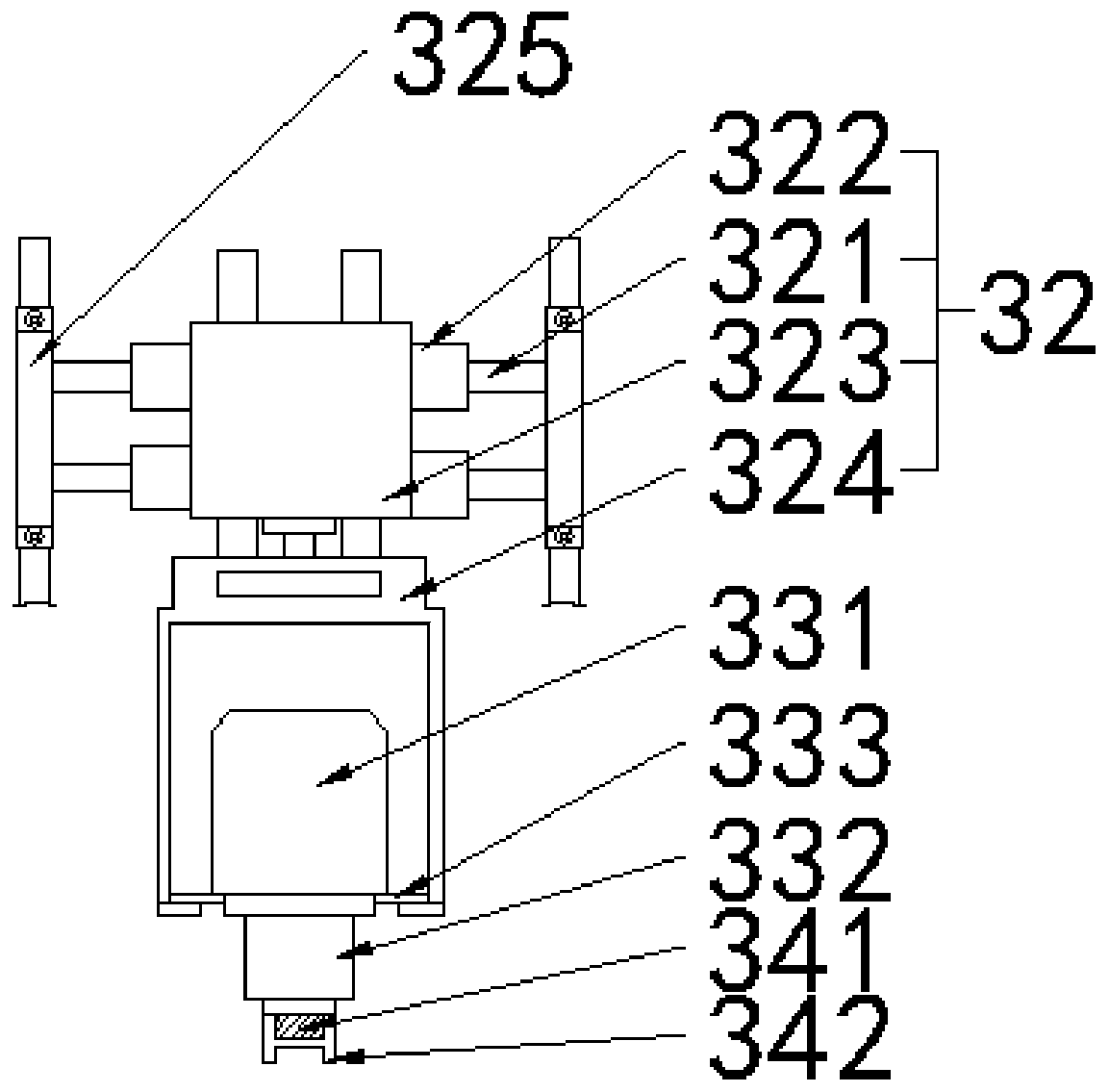

[0036] Such as Figure 1-Figure 6As shown, the present invention discloses a fully automatic assembly machine for bolts, including a workbench and a frame 2 fixedly installed on the workbench 1, and in a specific embodiment of the present invention, an assembly mechanism 3 for bolt assembly is also included 1. The automatic feeding mechanism 4 arranged on both sides of the assembly mechanism 3 and the support member 5 for supporting the bolts in the assembly process; the assembly mechanism 3 is arranged on the frame 2 by laterally sliding the horizontal drive mechanism 6; the automatic The feeding mechanism 4 is fixedly installed on the workbench 1; the support member 5 is arranged on the workbench 1 directly below the assembly mechanism 3; the workbench 1 is provided with a qualified transportation channel 11 and an unqualified transportation channel 12.

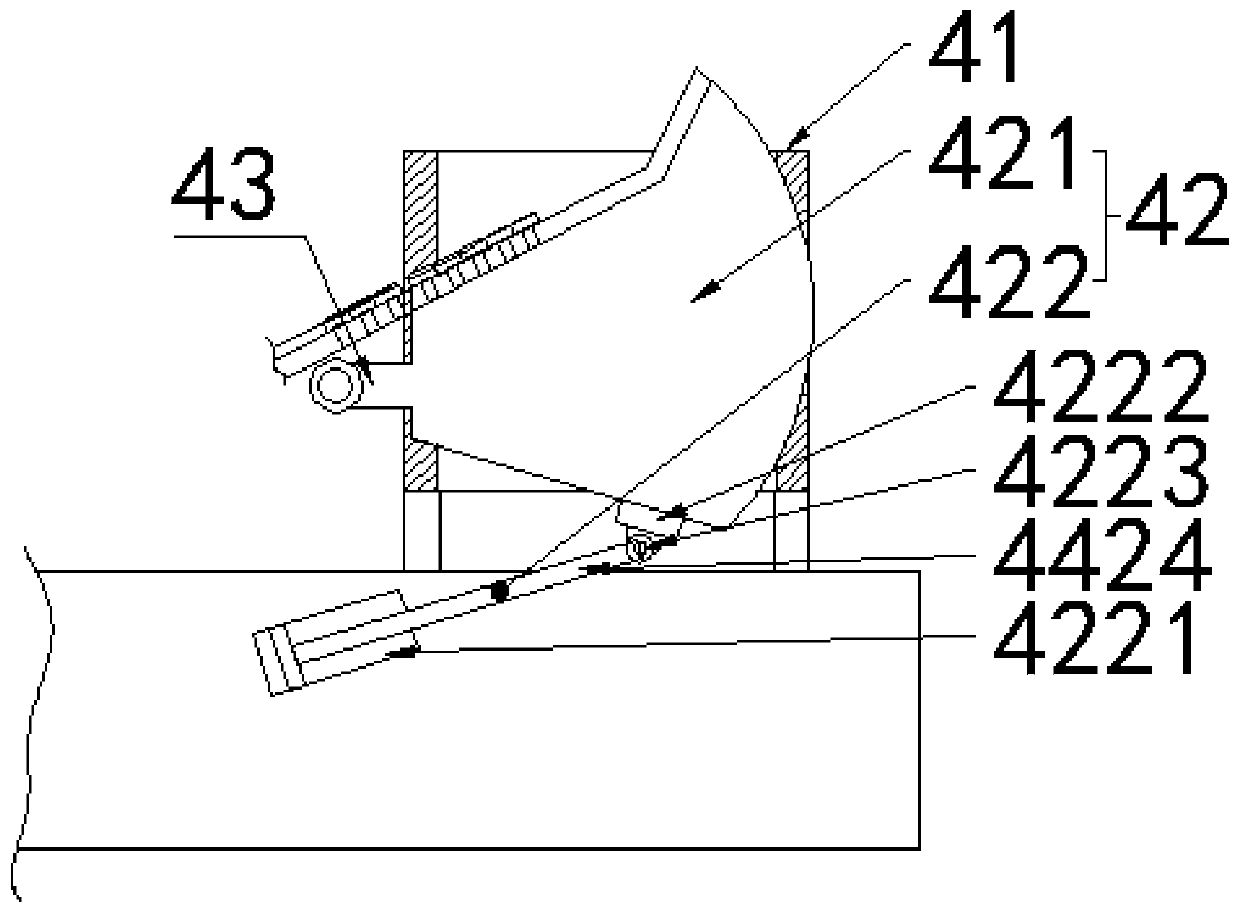

[0037] In a specific embodiment of the present invention, the automatic feeding mechanism 4 includes a storage box 41 fix...

Embodiment 2

[0053] In a specific embodiment of the present invention, a bolt assembly method includes the following steps:

[0054] S1 material preparation: first, the staff pours the produced studs and nuts into the storage boxes of the automatic feeding mechanism on both sides of the assembly mechanism; carry out material preparation;

[0055] S2 feeding: the feeding device on the automatic feeding mechanism drives the feeding rack through the first driving cylinder to transport the studs and nuts to their respective transport rails;

[0056] S3 transportation: The studs in the transportation track can be adsorbed to the bottom of the drive bracket through the electromagnetic sticker on the adsorption device, and transported to the top of the support groove through the horizontal drive mechanism, while the nuts in the other transportation track pass through the nuts respectively. The longitudinal push part and the nut transverse push part are transported into the support groove;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com