Coiled material and container multipurpose transport vehicle

A technology for transporting vehicles and containers, applied in the field of multi-purpose transport vehicles for coiled materials and containers, can solve the problems of single transport function and the situation of returning empty vehicles, and achieve the effects of improving safety, meeting loading requirements, and reducing the height of the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

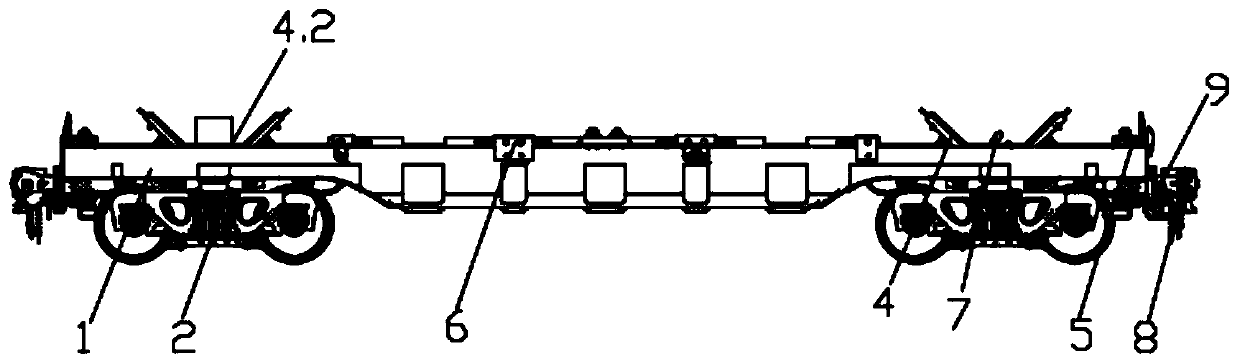

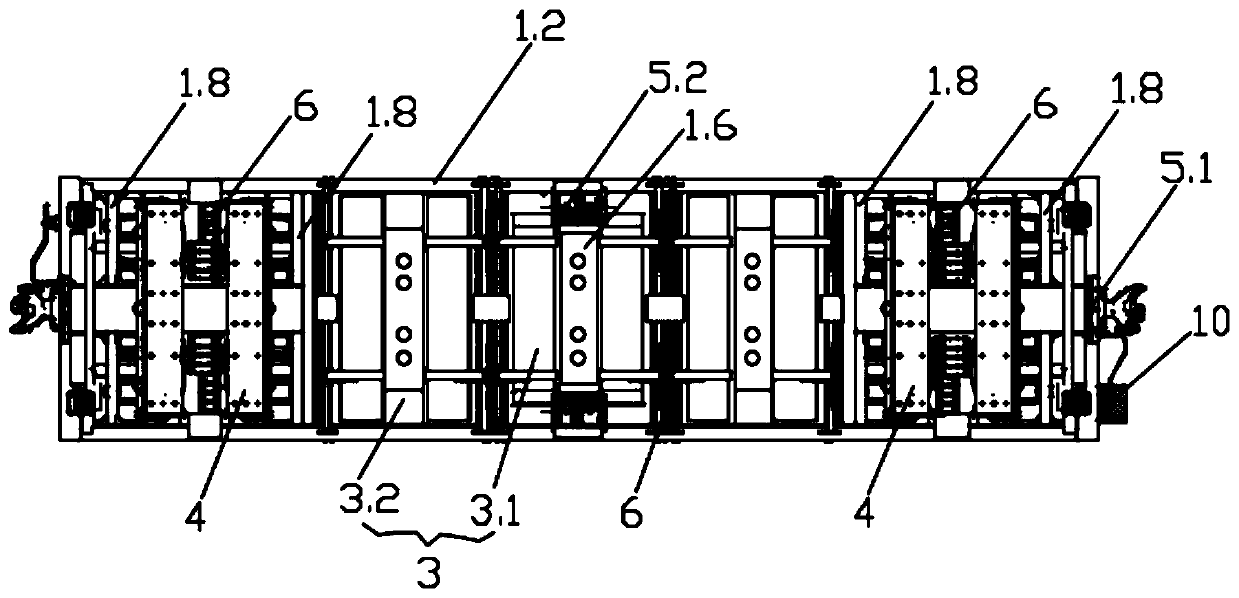

[0047] The embodiment is basically as figure 1 and figure 2 As shown: this embodiment provides a coiled material and container multi-purpose transport vehicle, which integrates the unique loading characteristics of coiled material transport and container transport, and is suitable for coiled material and container loading and transportation. The transport vehicle specifically includes a vehicle frame 1, a container lock The device 5, the middle bearing compartment 3 and the end bearing frame 4, each bottom of the two ends of the vehicle frame 1 is equipped with a bogie 2, the bogie 2 is the existing technology of the vehicle body, and is not an invention point of the present disclosure, so it will not be repeated here . The middle part of the frame 1 between the two bogies 2 has a concave bottom; the container locking device 5 is arranged on the frame 1, and the container locking device 5 specifically includes an end container twist lock 5.1 and a middle reversible container...

Embodiment 2

[0054] Embodiment 2 is basically the same as Embodiment 1, the difference is that in this embodiment, a concave mounting beam 3.1.6 is provided on the top of the connecting partition 3.1.2 of the carrying compartment 3.1, and the mounting beam 3.1.6 Located between the two support plates 3.1.1, the installation beam 3.1.6 is provided with a central transverse locking device 6 for reinforcing the inner coil of the V-shaped groove 3.2, specifically, please refer to Figure 5 As shown, the middle lateral locking device 6 includes a fixed plate 6.1 fixedly installed at both ends of the installation beam 3.1.6 and a guide mechanism arranged between the two fixed plates 6.1. 6.2 is respectively sleeved with two fixed arms 6.3 and locking pieces that match the fixed arms 6.3, and the locking pieces are located on the other side of the fixed arm 6.3 relative to the coil, so that the fixed arm 6.3 can move along the V-shaped groove 3.2 When the inner coil moves axially and reaches the ...

Embodiment 3

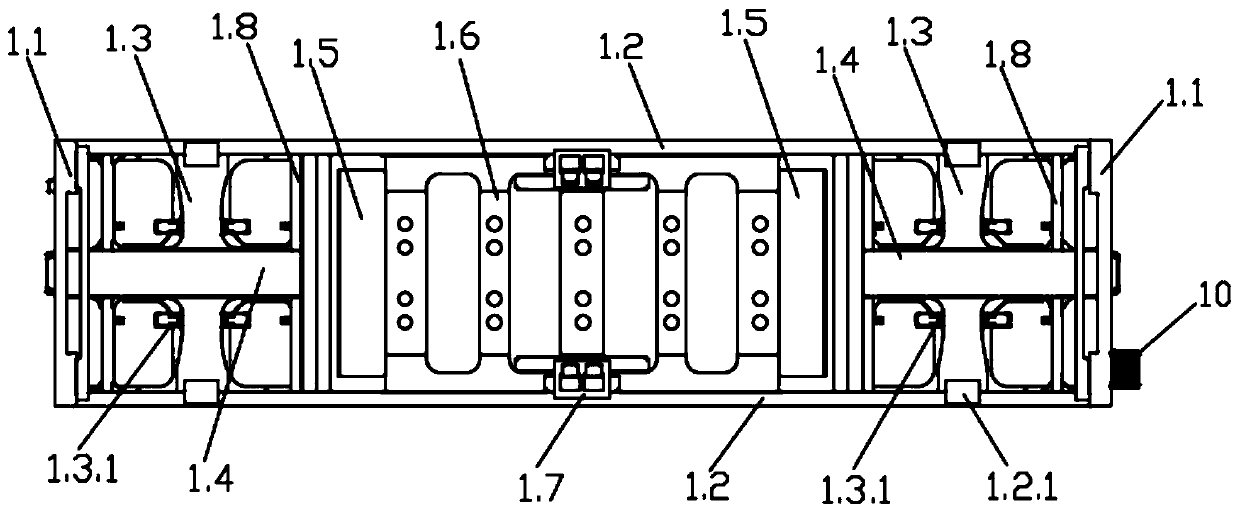

[0059] Embodiment 3 is basically the same as Embodiment 2, the difference is that the end carrier 4 provided in this embodiment includes two support frames 4.3, such as Figure 6 As shown, the two supporting frames 4.3 are set opposite each other and each has a supporting surface 4.3.2. Rubber sheets are laid on the two supporting surfaces, and the rubber sheets can be connected to the supporting frames by bonding or fasteners. Contacting the coil can effectively increase the friction between the coil and the contact surface, and act as a flexible buffer to prevent the surface of the plate from being worn; thus, the two supporting frames 4.3 form a V-shaped structure for loading the coil when it is lifted 4.2, and the support frame 4.3 forms a 1.3.1 rotational connection with the mounting seat through the hinge 4.3.1; specifically, as Figure 7 As shown, the mounting seat composition 1.3.1 includes a seat plate 131 fixed on the corbel composition 1.3, a U-shaped bottom plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com