A filling device for collecting corn

A filling device, corn technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of corn slipping, low filling efficiency, inconvenient collection of corn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

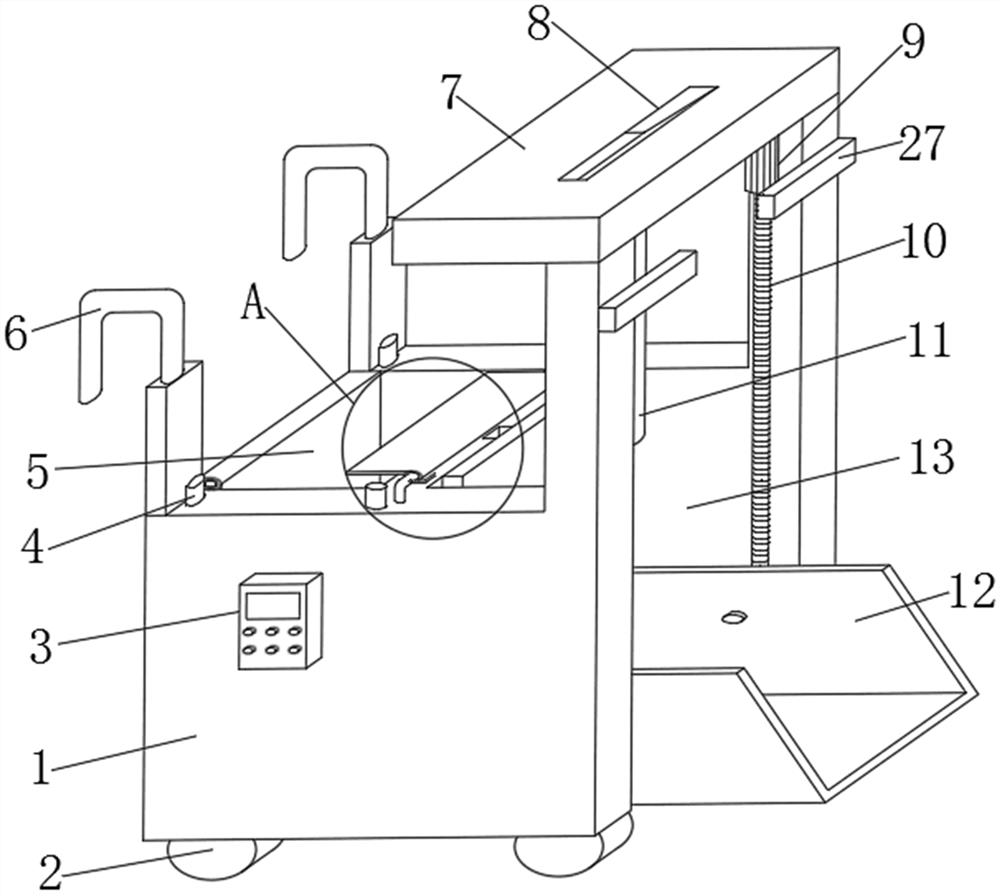

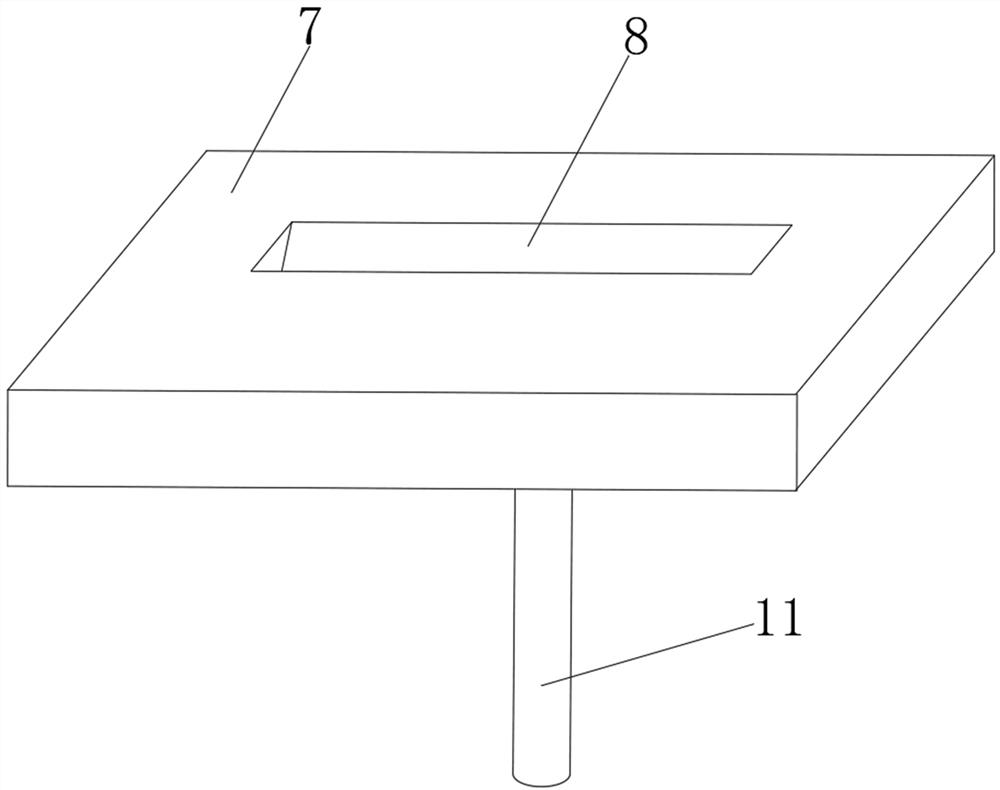

[0026] Such as Figure 1-6 As shown, a filling device for collecting corn comprises a main frame 1, one side of the main frame 1 is provided with a filling chamber 5, the other side of the main frame 1 is provided with a collection chamber 13, and the inside of the collection chamber 13 is provided with Collection box 12, one side of the upper end of main body frame 1 is fixedly installed with upper top plate 7, the other side of the upper end of main body frame 1 is fixedly installed with two groups of handles 6, and the lower end of upper top plate 7 is fixedly installed with two groups of motors 9.

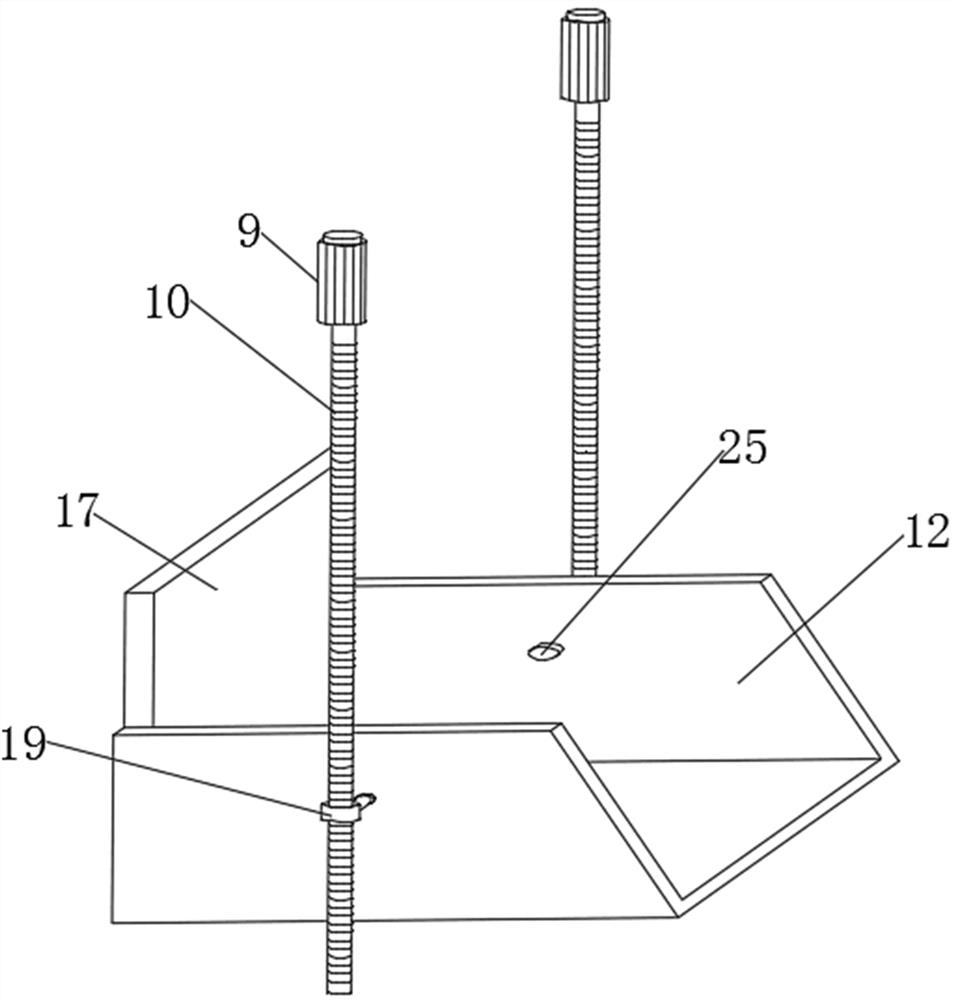

[0027] The rotating shaft at the lower end of the motor 9 is fixedly equipped with a screw rod 10, the outside of the screw rod 10 is provided with a screw collar 19, the outer surface of the screw rod 10 is provided with an external thread, and the inside of the screw collar 19 is provided with an internal thread, and the internal thread and The external thread is movably conn...

Embodiment 2

[0032] Such as Figure 1-7 As shown, a filling device for collecting corn comprises a main frame 1, one side of the main frame 1 is provided with a filling chamber 5, the other side of the main frame 1 is provided with a collection chamber 13, and the inside of the collection chamber 13 is provided with Collection box 12, one side of the upper end of main body frame 1 is fixedly installed with upper top plate 7, the other side of the upper end of main body frame 1 is fixedly installed with two groups of handles 6, and the lower end of upper top plate 7 is fixedly installed with two groups of motors 9.

[0033] The upper end of the main body frame 1 is fixedly installed with four sets of hanging columns 4 and fixed rods 18 respectively, and the four groups of hanging columns 4 are respectively located at the four corners of the upper end of the filling chamber 5, and the outside of the fixed rod 18 is sleeved with a sleeve 14, and the fixed rod 18 It is movably connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com