HDPE water supply pipe machining conveying device

A technology for conveying devices and water supply pipes, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of reducing friction and not being able to convey with different sizes and radii, and achieve reduced friction and good clamping effect , strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

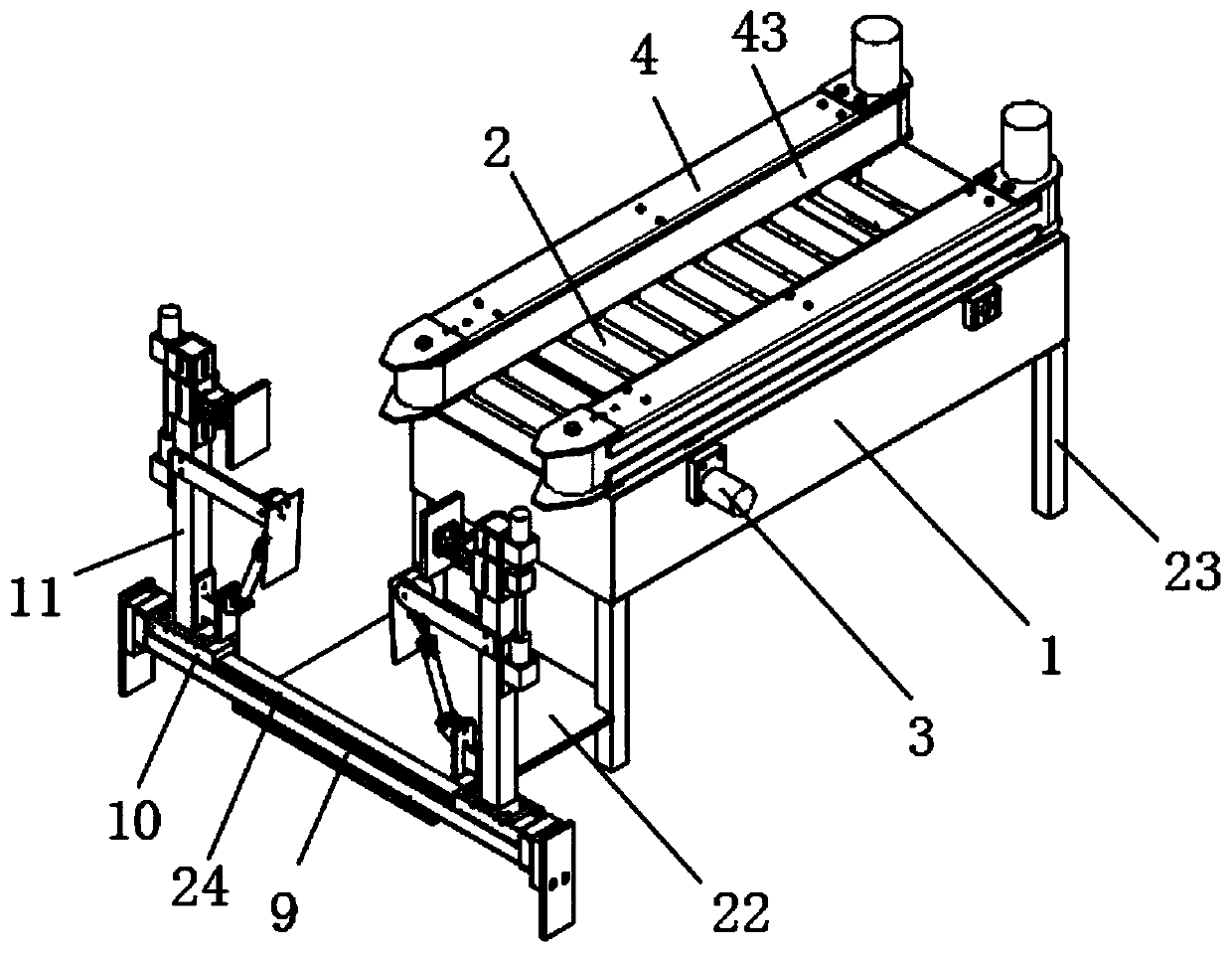

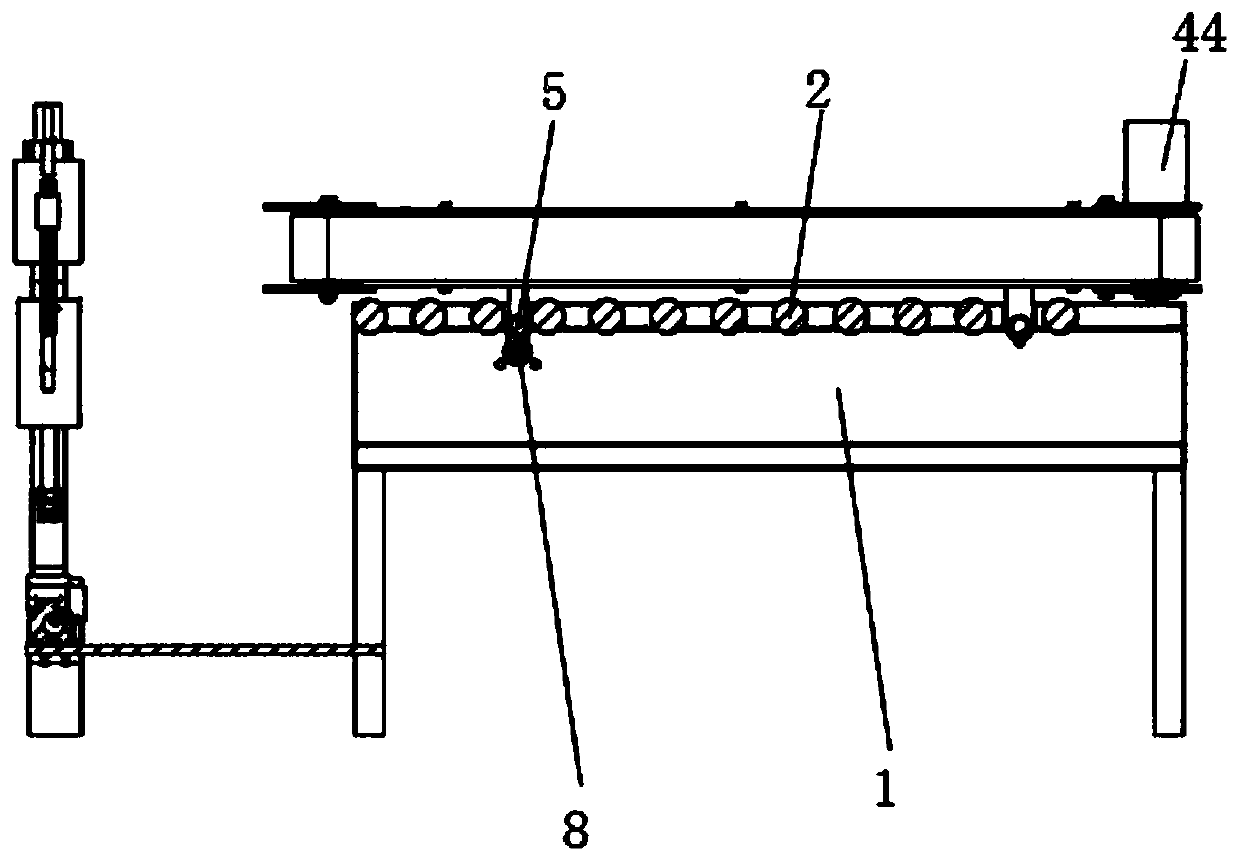

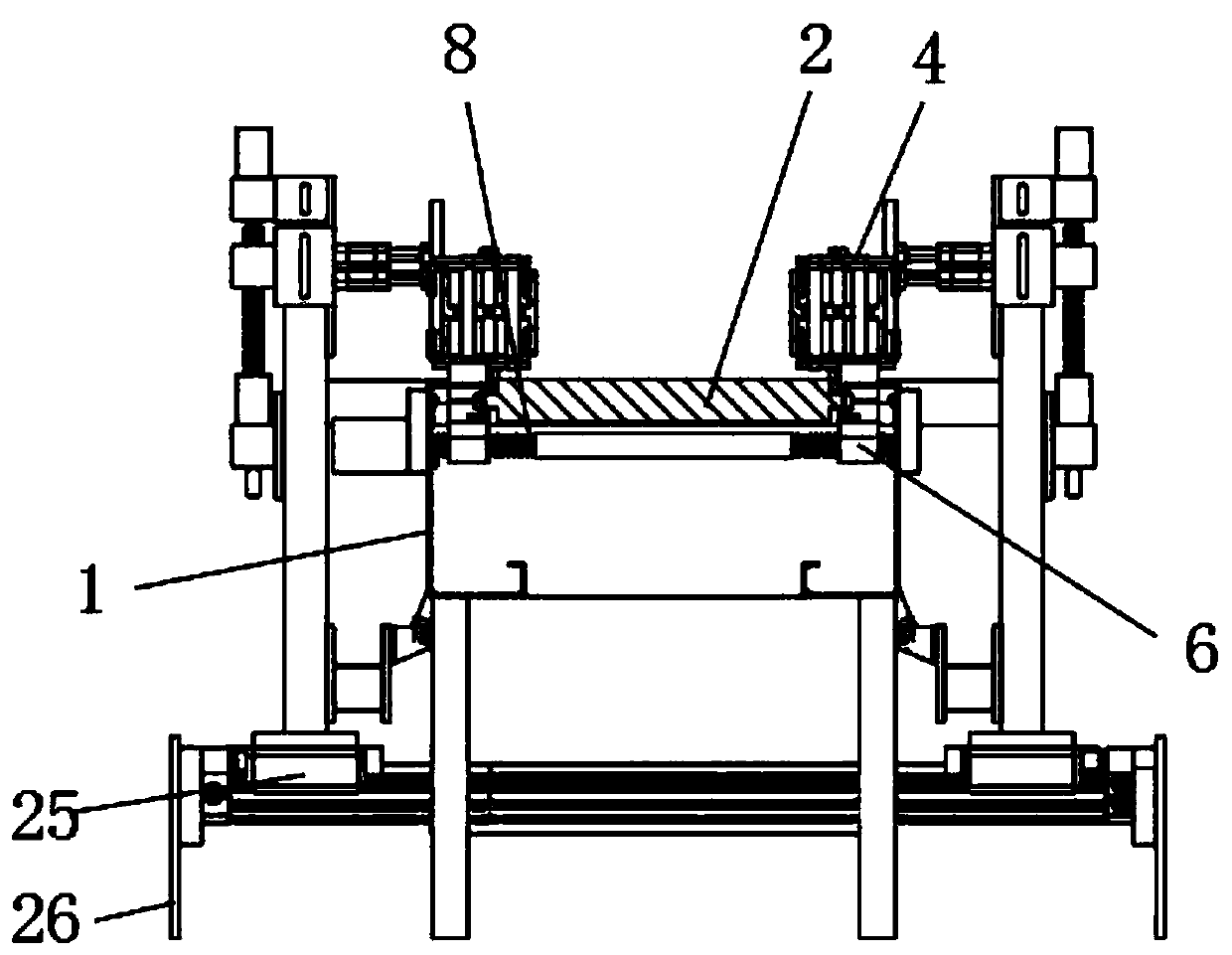

[0032] Such as Figure 1-5As shown, a HDPE water supply pipe processing and conveying device includes a support base 1, the support base 1 is a cuboid structure that runs through the upper and lower sides, and two transmission mechanisms 4 are arranged above the support base 1. The transmission mechanism 4 is symmetrically distributed, and several support rollers 2 are arranged on the inner side of the support seat 1;

[0033] Described transmission mechanism 4 comprises top plate 41 and bottom plate 46 that are distribute...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap