Soil squeezing stress eliminating method and construction step of soil squeezing stress eliminating thereof

A technology of stress relief and construction steps, applied in excavation, infrastructure engineering, protection devices, etc., can solve problems such as existing building damage and safety hazards, and achieve the effect of eliminating damage, economical feasibility, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

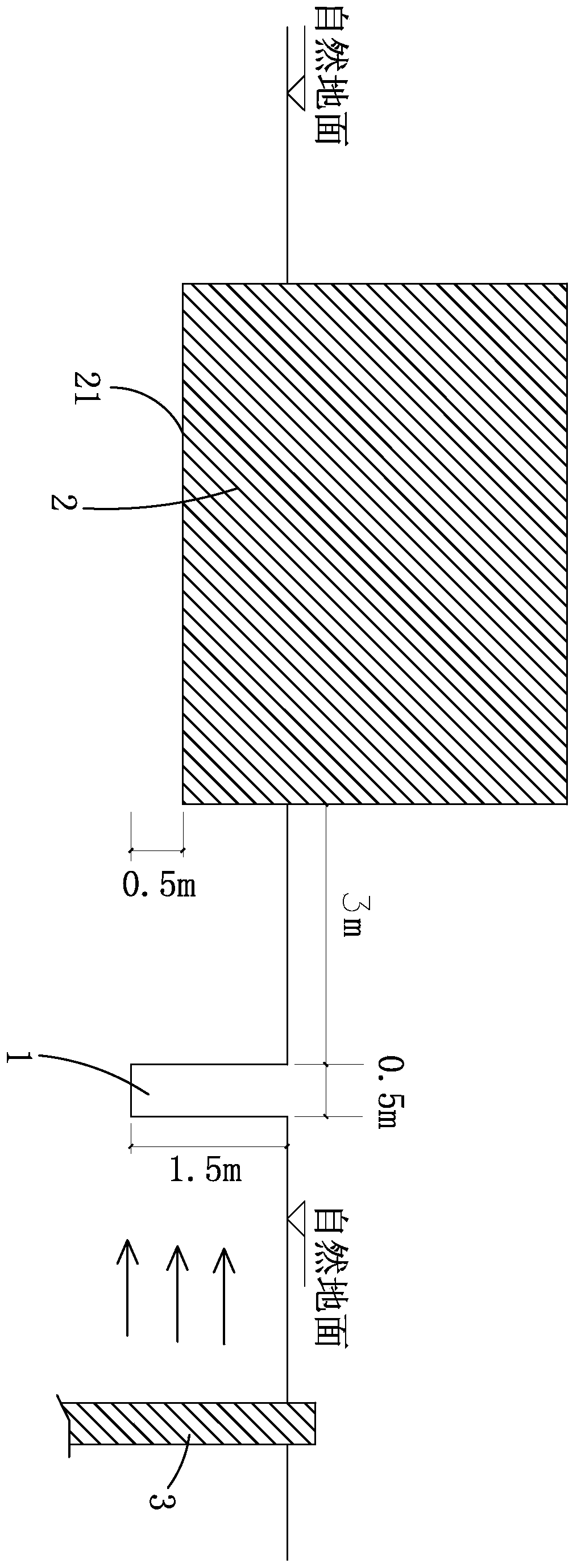

[0020] Example, combined with figure 1 As shown in the figure, a method for relieving the stress of soil extrusion is to dig a soil extrusion stress relief ditch 1 with a width of 0.5m and a depth of 0.5m lower than the depth of the foundation bottom of the existing building. 2, the other side of the soil-squeezing stress relief ditch 1 is provided with a soil-squeezing pile 3.

[0021] A construction method for squeezing soil stress relief ditch, comprising the following steps:

[0022] Step 1: Excavating a soil-extruded stress relief ditch 1 with a depth of 0.5m and a width of 0.5m at a depth of 3 m from the existing building 2;

[0023] Step 2: Slope excavation is not required during excavation of soil compaction stress relief ditch 1;

[0024] Step 3: The excavated soil cannot be piled on the side of the stress relief ditch 1;

[0025] Step 4: During the construction of the soil-squeezing pile 3, ensure that the soil-squeezing stress relief ditch 1 is not filled.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com