Plate hoisting structure for house building construction

A technology for building construction and panels, applied in building construction, building material processing, construction, etc., can solve problems such as damage to the loading frame, violent collision between the loading frame and the guard plate, and no braking device for the loading frame. Possibility of damage, effect of mitigating rigid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

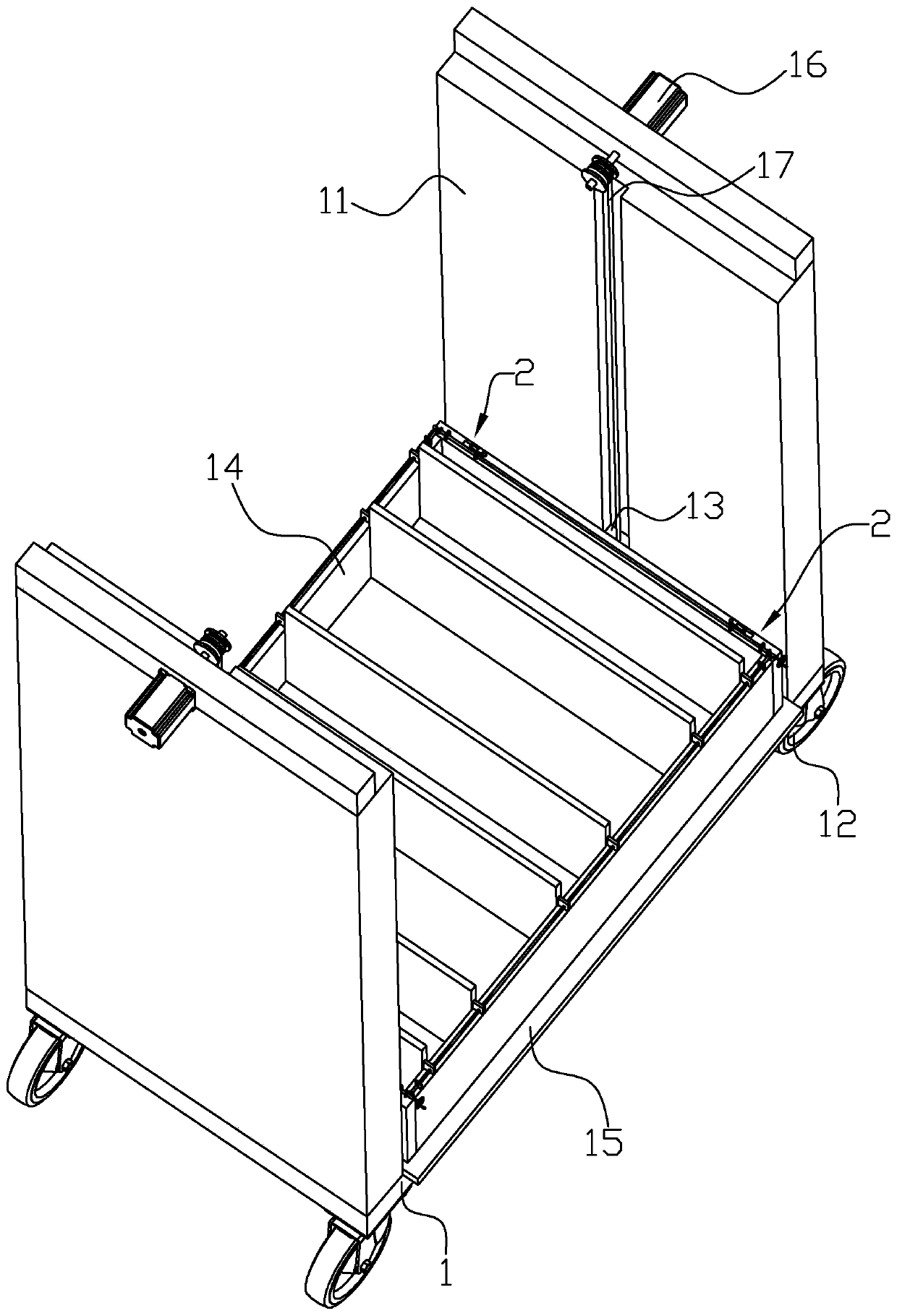

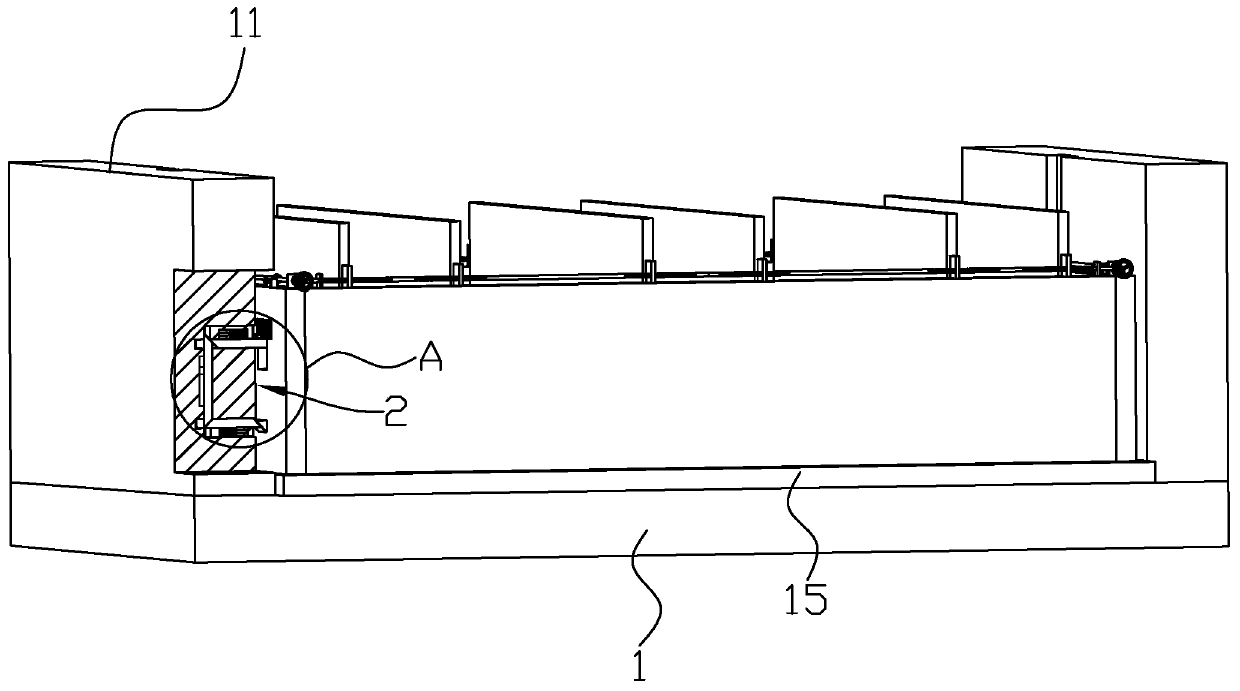

[0038] Embodiment: a kind of board material hoisting structure that is used for building construction, as figure 1 and figure 2 As shown, it includes a base plate 1, a column 11, a roller 12, a slide plate 13, a loading frame 14, a guard plate 15, a brake motor 16, and a lifting rope 17; Between 11 and the loading frame 14 are installed multiple sets of braking devices 2 for braking the loading frame 14 .

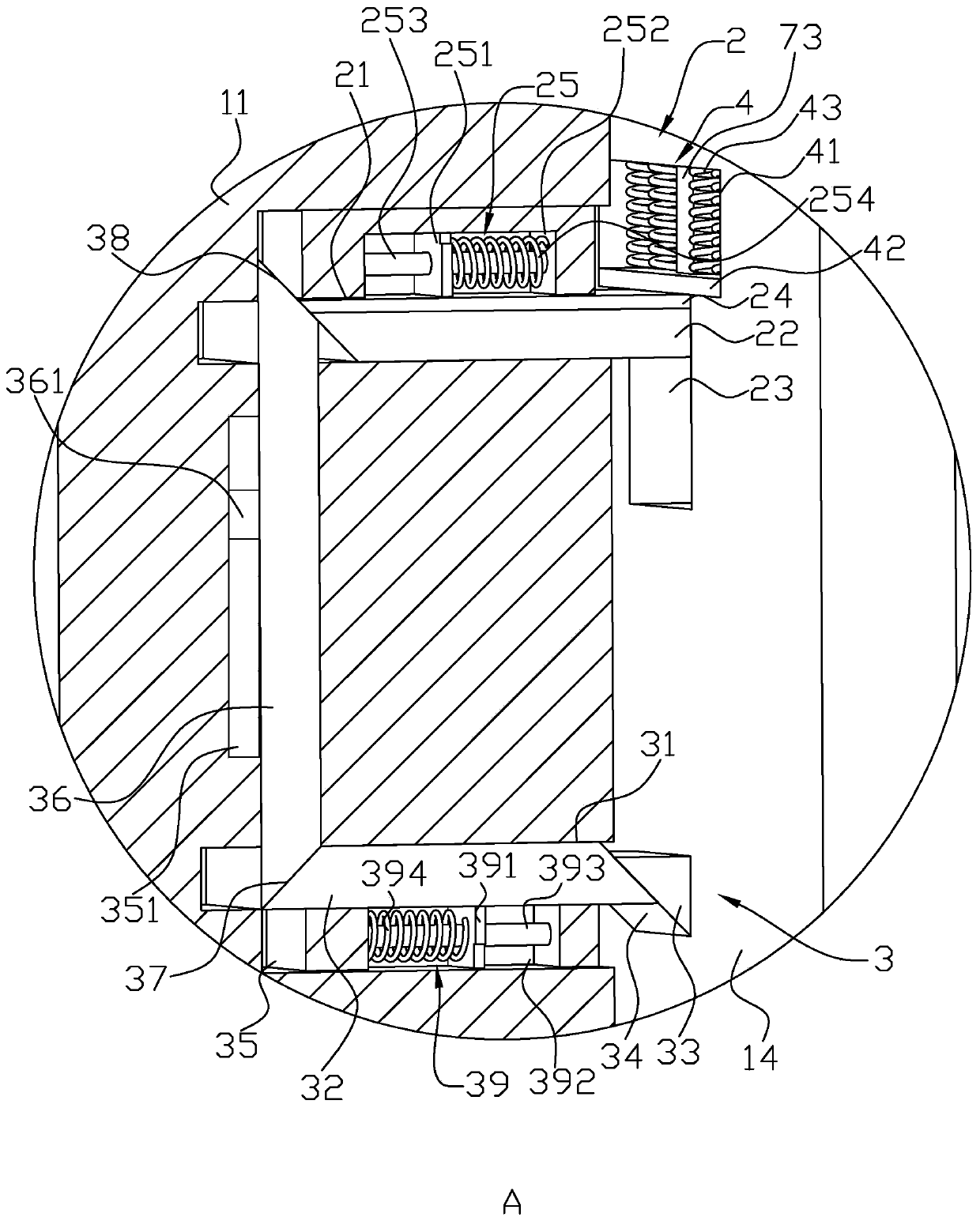

[0039] Such as figure 2 and image 3 As shown, each set of braking devices 2 includes a first horizontal slot 21 opened on the side of the column 11 close to the loading frame 14, a brake plate 22 slidingly connected to the first horizontal slot 21 in the horizontal direction, installed on the column 11 and The driving mechanism 3 used to drive the brake plate 22 between the loading frames 14 to move, the first reset assembly 25 installed in the first horizontal groove 21 to drive the brake plate 22 to reset, and the opening on the loading frame 14 close to the column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com