Tunnel supporting formwork for civil engineering

A civil engineering and support plate technology, which is applied in earth-moving drilling, mine roof support, mining equipment, etc., can solve the problem that the tunnel construction support device cannot be adjusted in different tunnels, etc., to solve the complex installation and disassembly, improve the stability of use, transfer handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

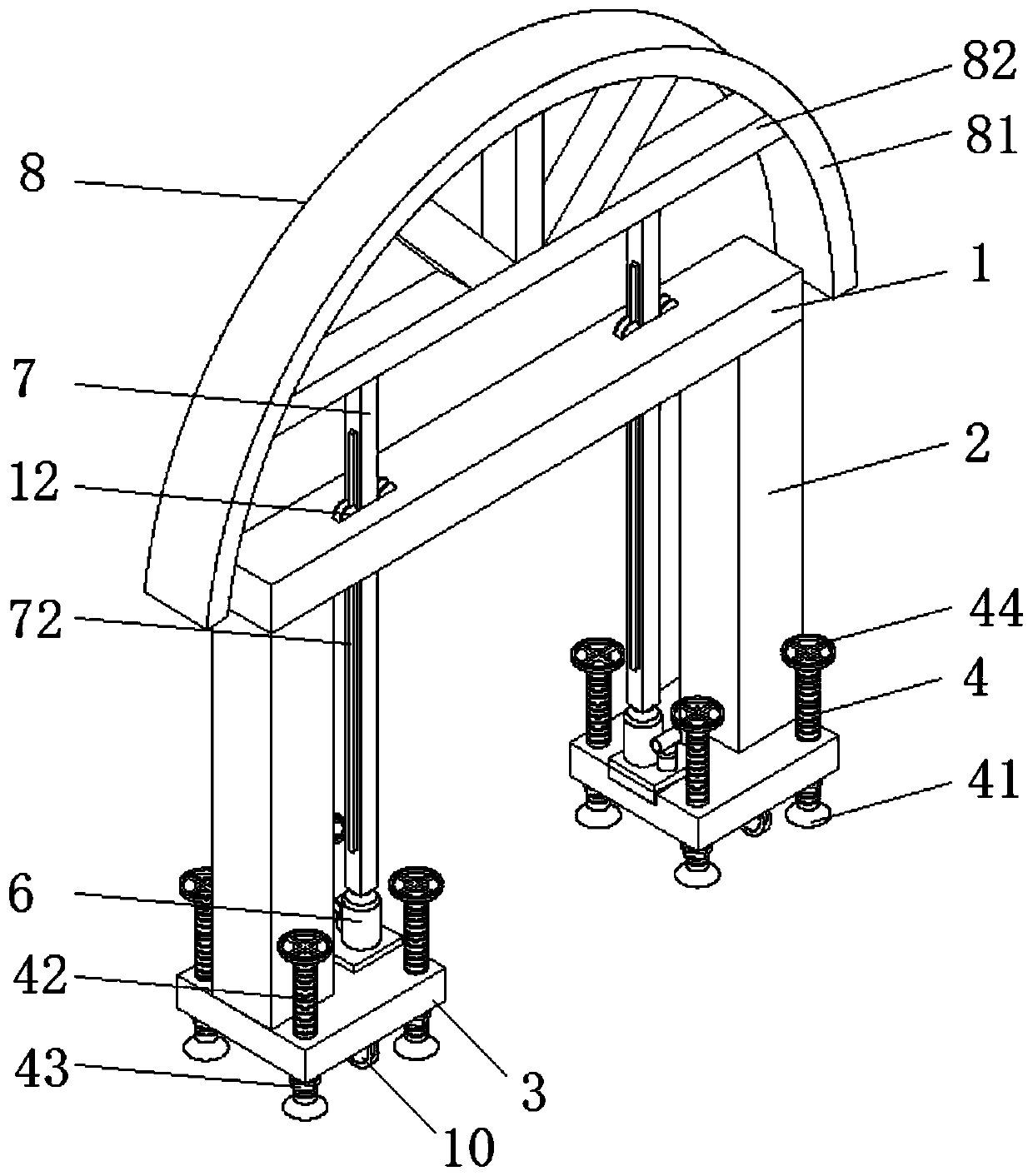

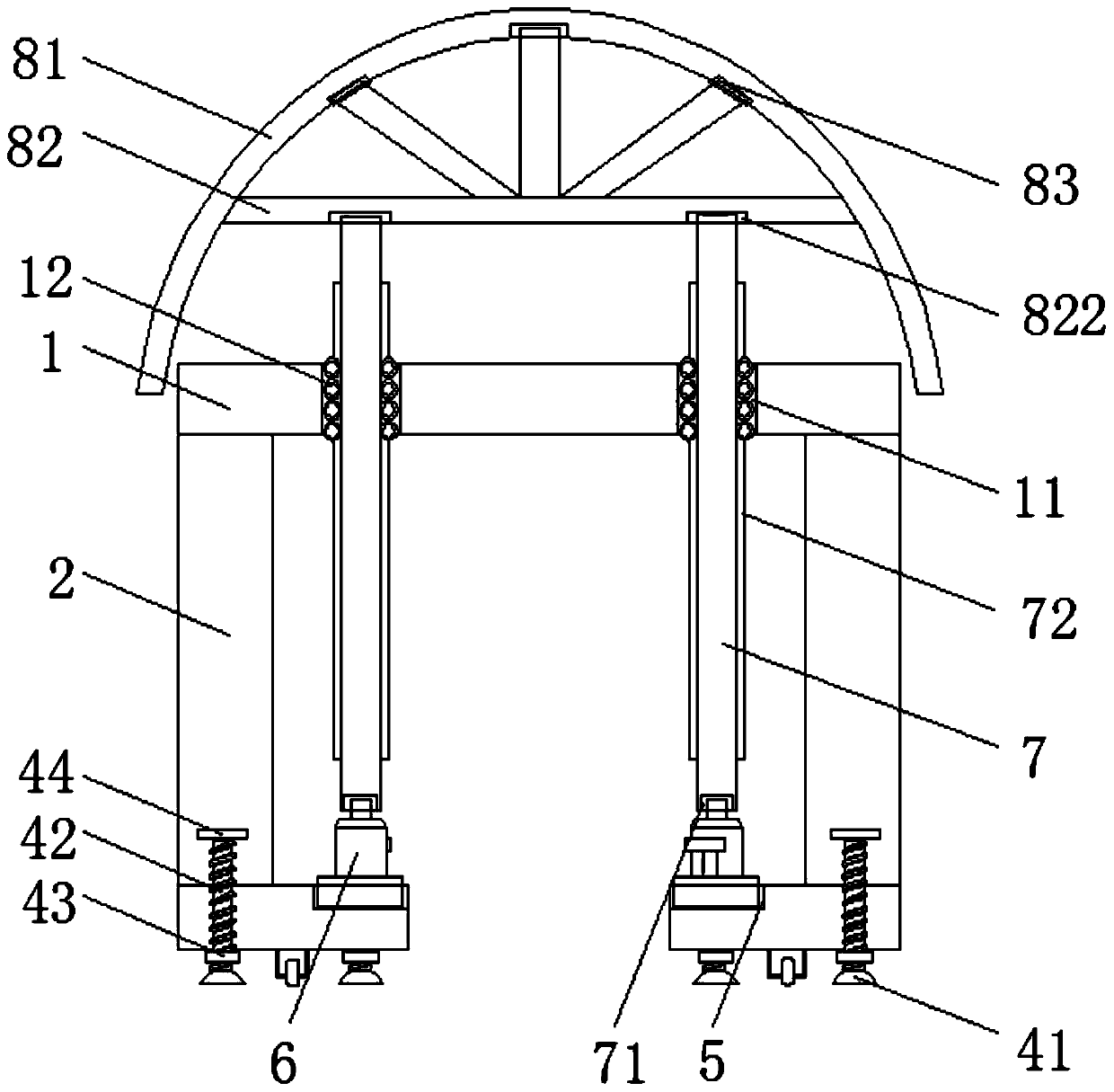

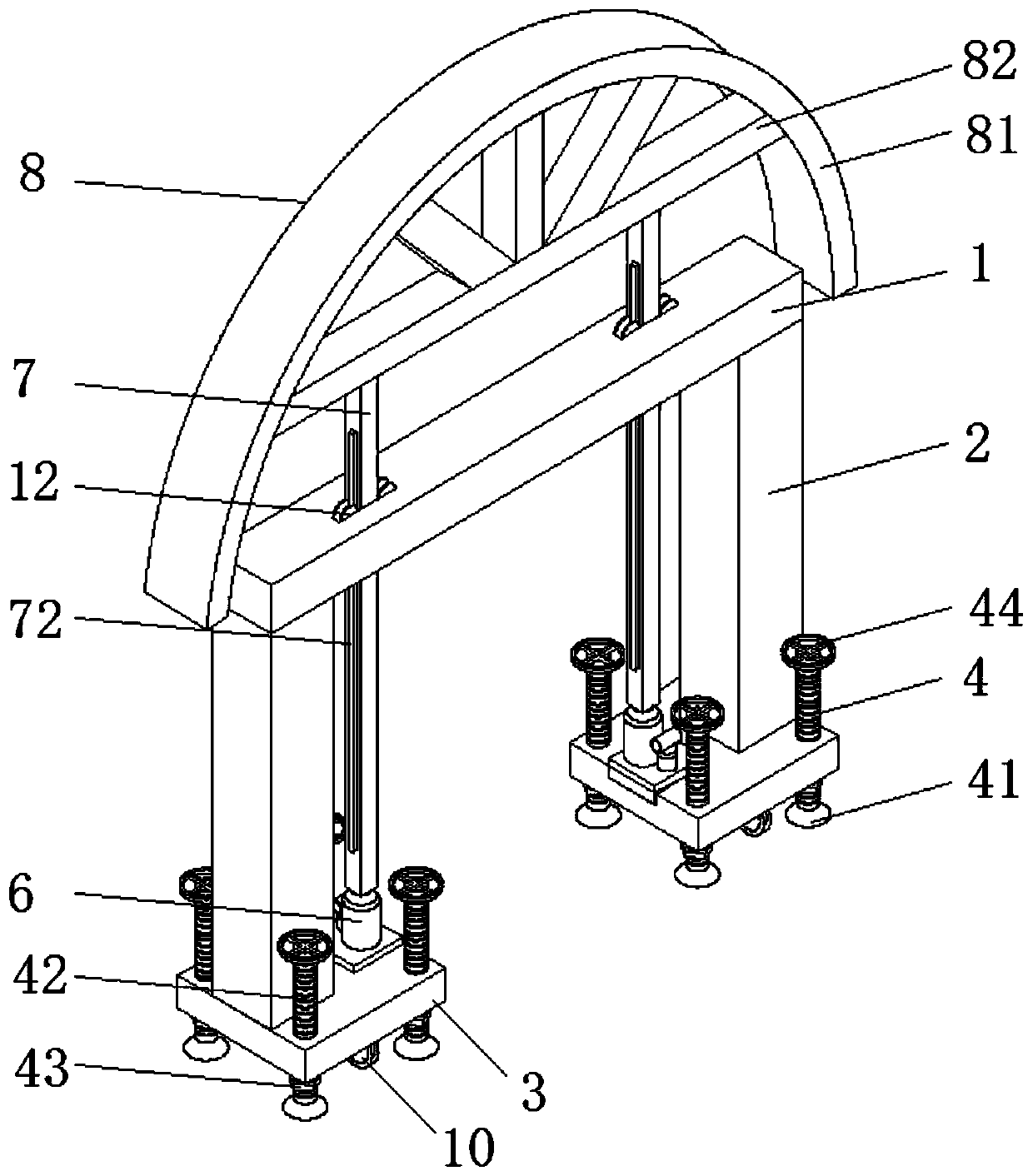

[0026] like figure 1 and figure 2 The shown tunnel support formwork for civil engineering includes a support plate 3, on which the support column 2 is fixedly connected, on which the support column 2 is fixedly connected to the beam frame 1, and a base 41 is arranged under the support plate 3, and the support A first lifting mechanism 4 is arranged between the board 3 and the base 41 ; a frame body 8 located above the beam frame 1 is also included, and a second lifting mechanism is arranged between the frame body 8 and the support plate 3 or the beam frame 1 .

Embodiment 2

[0028] like figure 1 and figure 2 The shown tunnel support formwork for civil engineering is implemented in the following manner:

[0029] It includes a beam frame 1, a support plate 3 and a first lifting mechanism 4. Both ends of the bottom of the beam frame 1 are provided with support columns 2, and the bottom end of the support column 2 is provided with a support plate 3. The first lifting mechanism 4 runs through the square support The four corners of the plate 3, one end of the support plate 3 is provided with a fixed groove 5, the fixed groove 5 is provided with a jack 6 and connected by bolts, the top of the jack 6 is provided with a push rod 7, the bottom of the push rod 7 is provided with a top groove 1 71, and the jack 6 The top is nested in the top groove 1 71, slide rails 72 are provided on both sides of the ejector rod 7 and connected by bolts, the two ends of the beam frame 1 are oppositely provided with rolling through holes 11, and the two ends of the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com