Integrated cooker with mute oil fume suction device and manufacturing method thereof

A technology of integrated cooker and oil suction fume, which is applied in the field of integrated cooker, can solve the problems of increasing the noise of integrated cooker, reducing the service life of integrated cooker, affecting the working efficiency of integrated cooker, etc., so as to improve stability, improve stability and reliability, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

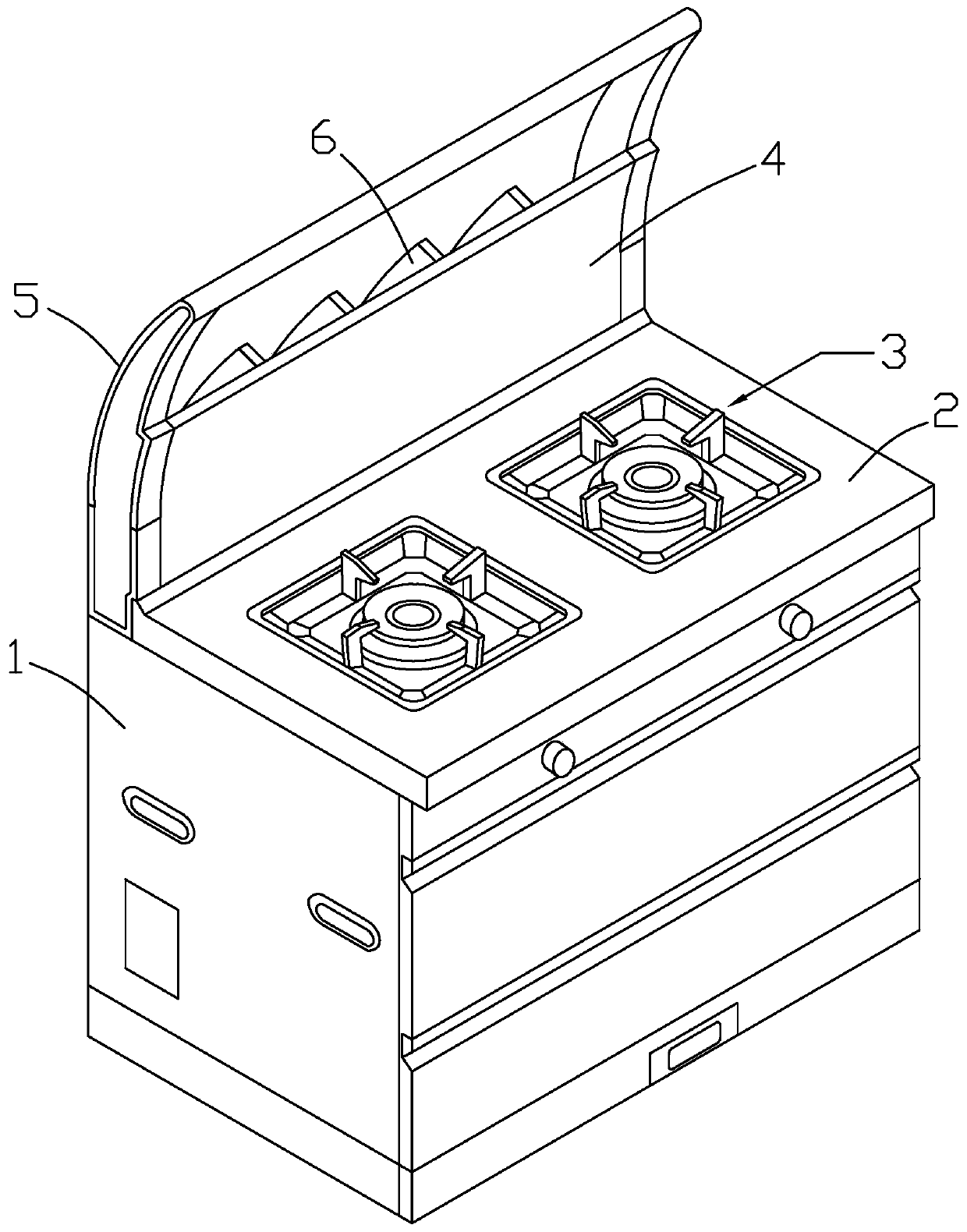

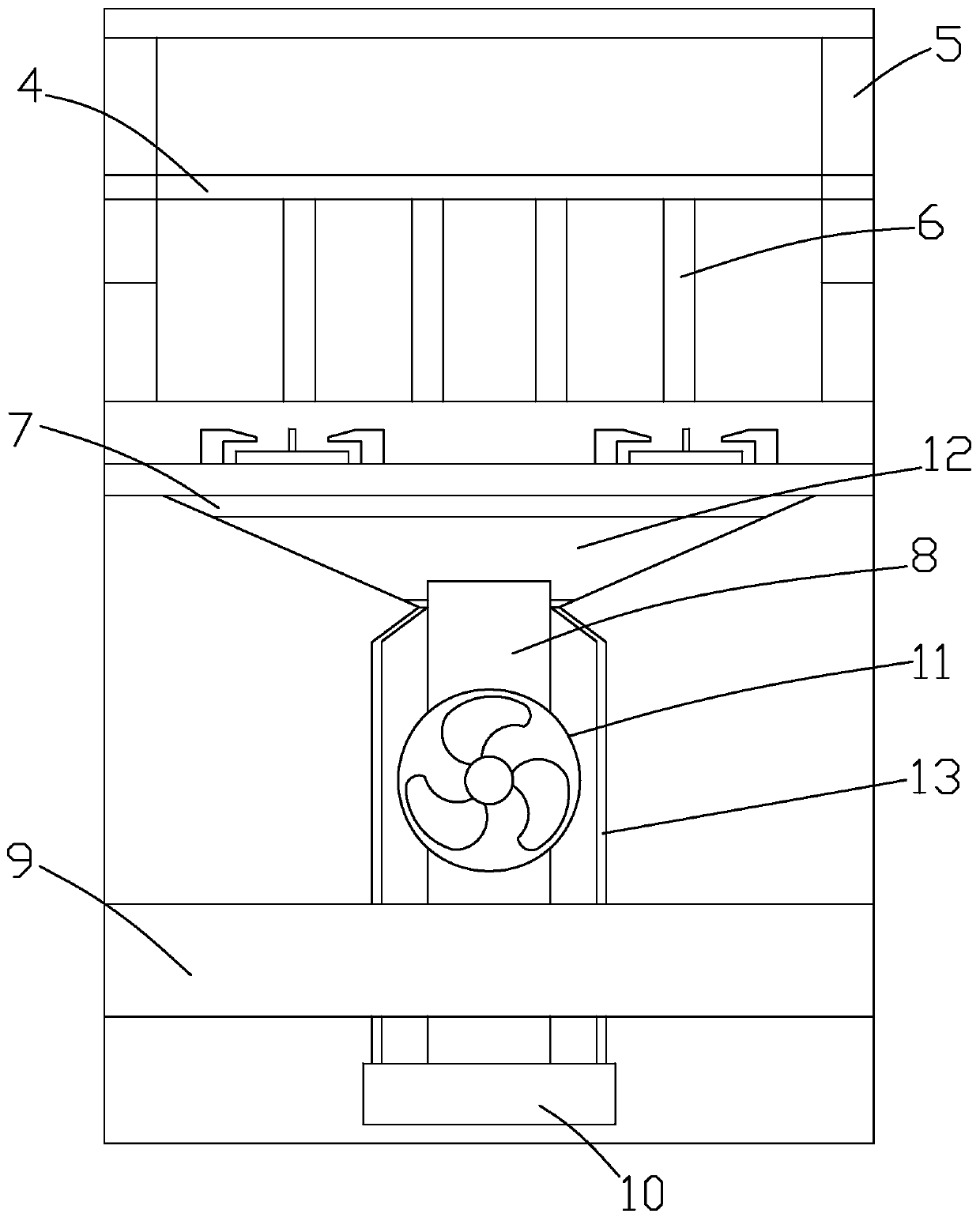

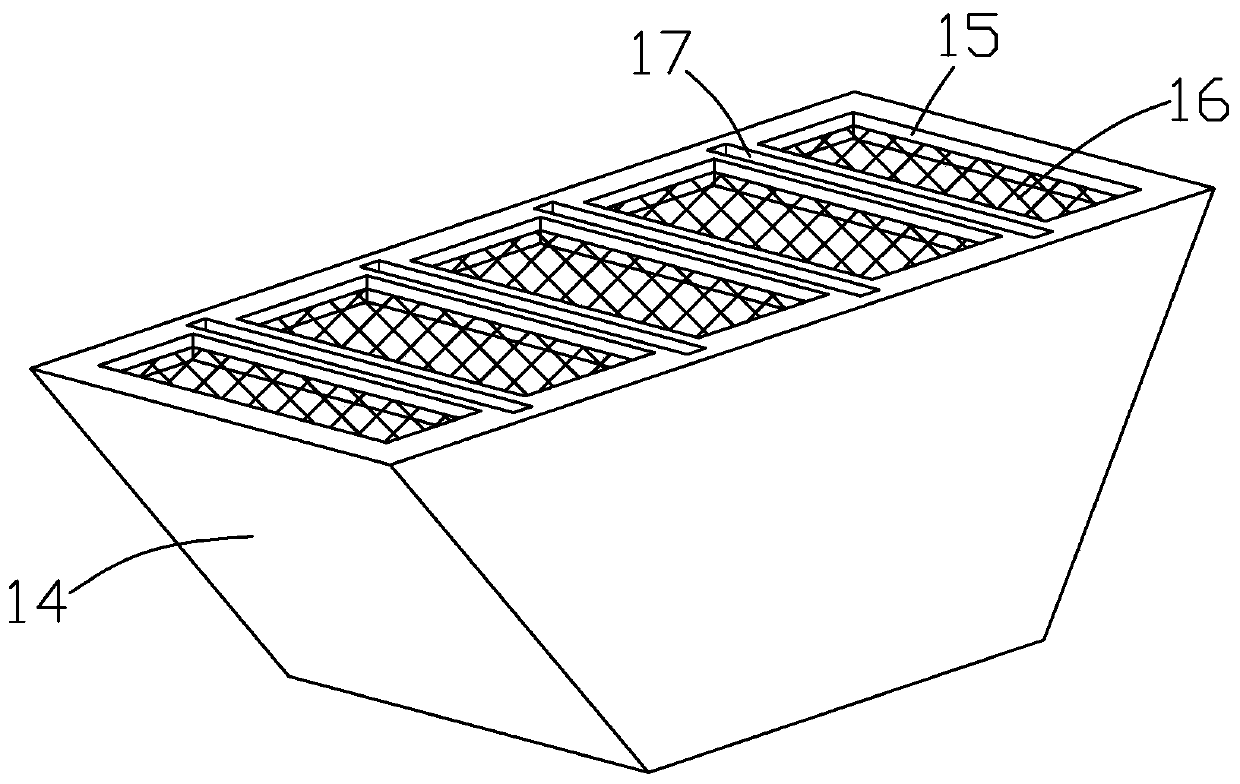

[0058] Such as Figure 1 to Figure 8 As shown, it is an integrated cooker with a silent oil suction device according to the present invention, which includes an integrated cooker body 1, a glass platen 2 is arranged on the top surface of the integrated cooker body 1, and a cooker 3 is arranged on the glass platen 2. The interior of the stove body 1 is provided with a smoke collection chamber 7, a smoke guide pipe 8 and a smoke exhaust pipe 9, the smoke collection chamber 7 is connected to the smoke exhaust pipe 9 through the smoke guide pipe 8, and the smoke guide pipe 8 is provided with a fan 11, integrated into the stove body The rear side of the top surface of 1 is provided with a rear baffle 5 and a smoke guide 4, and spacers 6 are uniformly arranged between the back baffle 5 and the smoke guide 4, and the spacers 6 include a base plate 30 and a second sound-absorbing layer 31. The two sound-absorbing layers 31 are symmetrically arranged on both sides of the base plate 30,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com