Ejection-type heat pump waste steam recycling heating mode and system based on complete thermoelectricity decoupling

A kind of spent steam recovery and ejection technology, which is applied in heating systems, hot water central heating systems, heating methods, etc. Problems such as steam flow imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

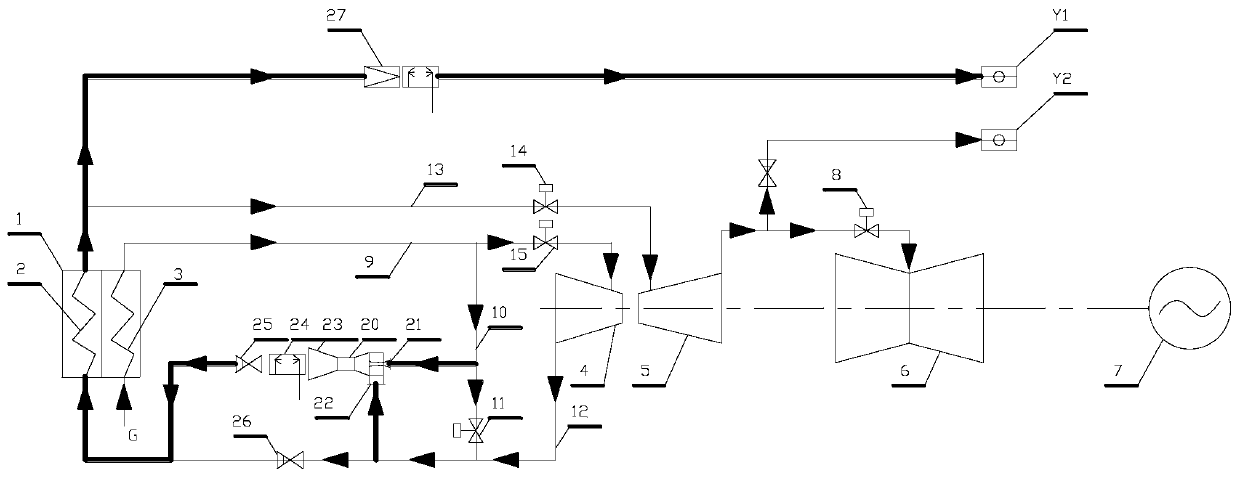

[0048] The specific embodiment 1 of the present invention is as follows.

[0049] Based on complete thermoelectric decoupling, ejector heat pump waste steam recovery and heating system, the system includes boiler superheated steam, reheater, steam turbine high pressure cylinder, medium pressure cylinder, low pressure cylinder, generator, decoupling injection device, Connecting pipelines, the decoupling injection device includes a gas distribution ejector 20, the high pressure of the gas distribution ejector 20 drives the main steam pipe between the steam inlet 21 and the outlet of the superheater 3 of the boiler 1 and the inlet of the high pressure cylinder 4 9 connected, the low-pressure steam inlet 22 of the gas distribution ejector 20 is connected with the exhaust port of the high-pressure cylinder 4 through the cold re-pipe 12, and the medium-pressure exhaust steam outlet 23 of the gas distribution ejector 20 is passed through the gas distribution desuperheater 24 and The ...

specific Embodiment 2

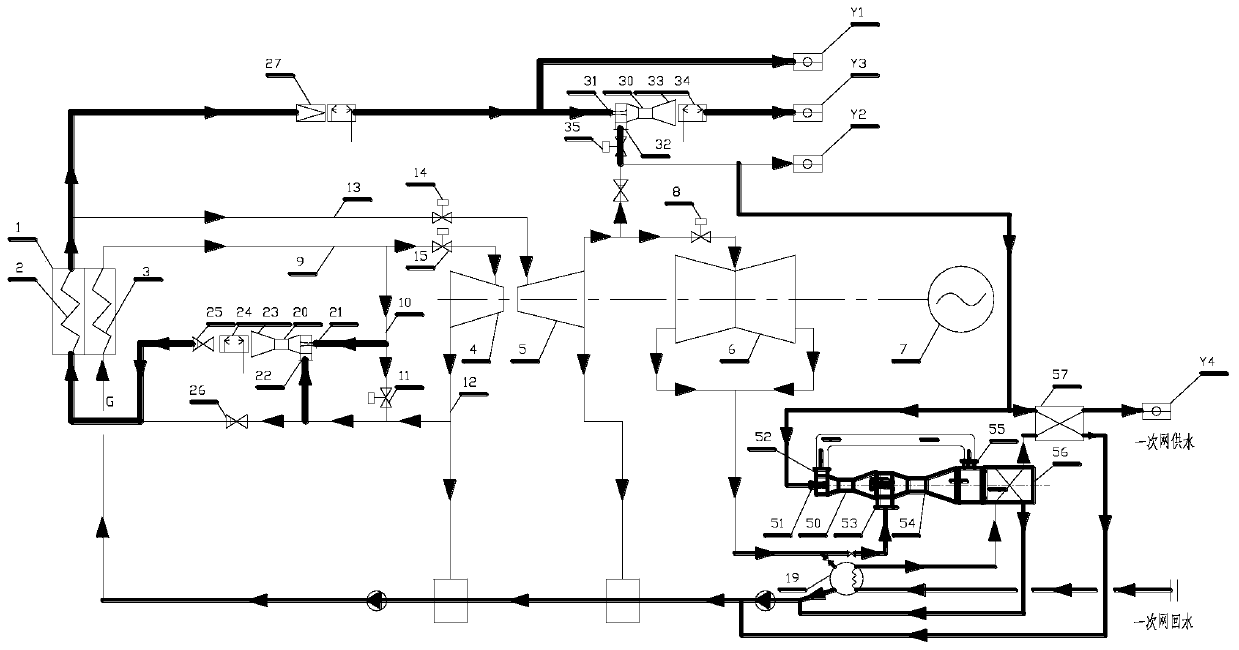

[0072] This specific embodiment is based on the specific embodiment 1. The decoupling injection device also includes a steam supply ejector 30, and the steam supply high pressure of the steam supply ejector 30 drives the steam inlet 31 and the external supply of the heat re-pipe 13. The steam extraction port is connected with the steam supply pipeline of the high-pressure steam user Y1, the steam supply low-pressure steam inlet 32 of the steam supply ejector 30 is connected with the steam exhaust port of the medium-pressure cylinder 5 and the gas supply pipeline of the low-pressure steam user Y2, and the steam supply lead The steam supply medium-pressure exhaust steam outlet 33 of the injector 30 communicates with the medium-pressure steam user Y3 through the steam supply desuperheater 34. The steam supply ejector 20 adopts a stepless adjustment joint adjustment structure.

[0073] The exhaust port of the low-pressure cylinder 6 is not only connected to the condenser 19, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com