Low-pressure cylinder switching and full-load heat supply method and system with built-in injection pressurizing pipe bundle

A low-pressure cylinder, full-load technology, applied in the field of cogeneration and waste heat recovery heating, can solve the problems of large land occupation and investment, difficult to effectively reduce the smoke temperature of the reheater, and increased workload, etc., to achieve no additional energy. energy consumption and raw material consumption, increase the flexibility of thermal power operation, increase the effect of power generation and heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

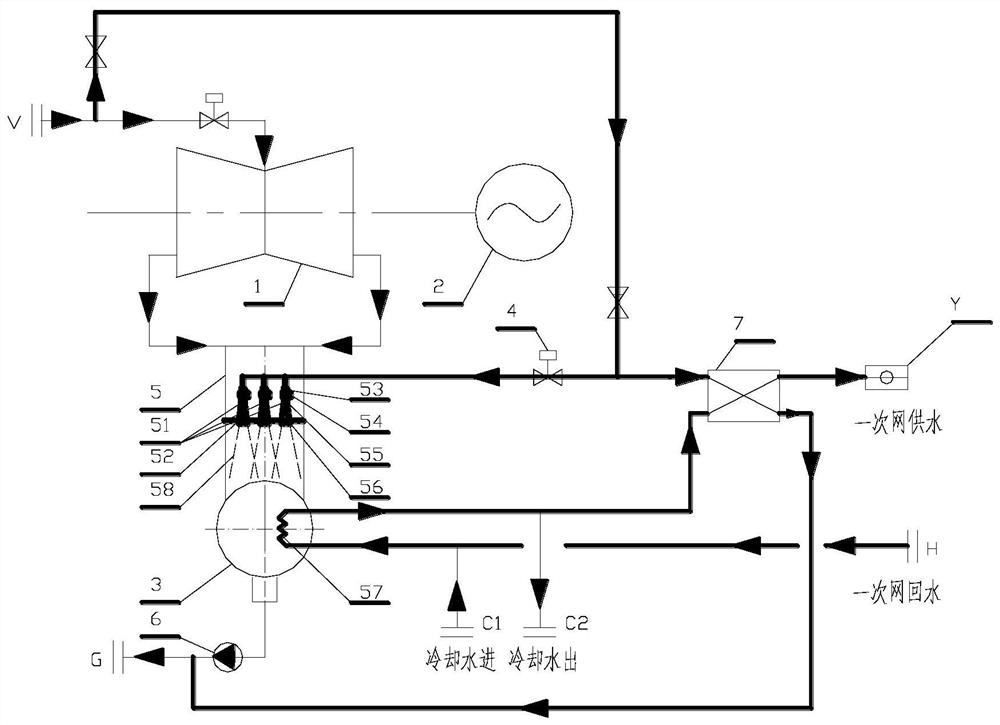

[0019] figure 1 It is a schematic diagram and an embodiment of the system of the present invention.

[0020] Specific examples of the present invention are as follows.

[0021] The method and system for low-pressure cylinder cut-off and full-load heating with built-in injection booster tube bundles are characterized in that: the exhaust steam communication pipe 5 between the exhaust port of the low-pressure cylinder 1 of the steam turbine and the condenser 3 is arranged inside the cavity There is a built-in low-pressure group jet injection tube bundle 51, which is composed of a group of unit ejectors 55, and the unit high-pressure drive steam inlet 53 of each unit ejector 55 is connected to the steam inlet of the low-pressure cylinder 1 It is connected with the steam inlet of the heat network heater 7, the unit low-pressure steam inlet 54 of the unit ejector 55 communicates with the upper low-pressure area of the exhaust steam communication pipe 5, and the unit medium-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com