Dehumidifier for capsule filling room and tablet drying room

A dehumidifier, room technology, applied in space heating and ventilation, space heating and ventilation details, applications, etc., can solve the problems of production failure, moldy tablets, and high temperature, to ensure normal production, avoid temperature increase, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

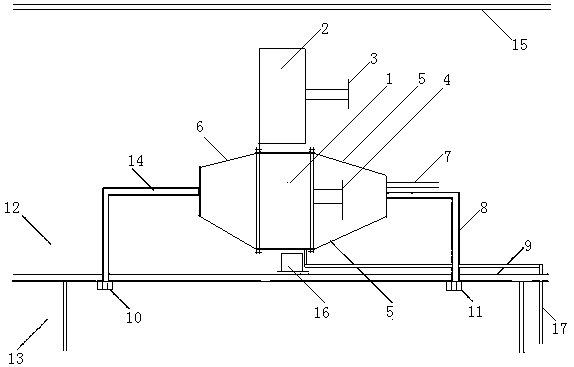

[0008] see figure 1 , and the names of the parts are as follows: surface cooler 1, radiator 2, heat dissipation fan 3, surface cooler fan 4, front-end fan cylinder 5, rear-end fan cylinder 6, ozone pipe 7, front air pipe 8, shed Plate 9, dry air inlet 10, wet air outlet 11, technical mezzanine 12, clean room 13, rear air duct 14, building roof 15, compressor 16, cooling drain 17.

[0009] see figure 1 , the capsule filling room and the film-drying room use dehumidifiers, the technical interlayer 12 above the shed board 9, and the purification room 13 below the shed board 9. It includes a surface cooler 1, a radiator 2, a heat dissipation fan 3, and a surface cooler fan 4. Put the dehumidifier in the technical interlayer 12 above the shed board 9 of the capsule filling room or the film drying room, unfold the surface cooler 1 and radiator 2 folded in the dehumidifier in parallel, and pass the surface cooler 1 through the front end of the air The barrel 5 is sealed with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com