Lens module

A lens module and lens technology, applied in the field of optical imaging, can solve the problems of complex lens module structure and lower production efficiency, and achieve the effects of simple structure, high production efficiency, anti-shake and auto-focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

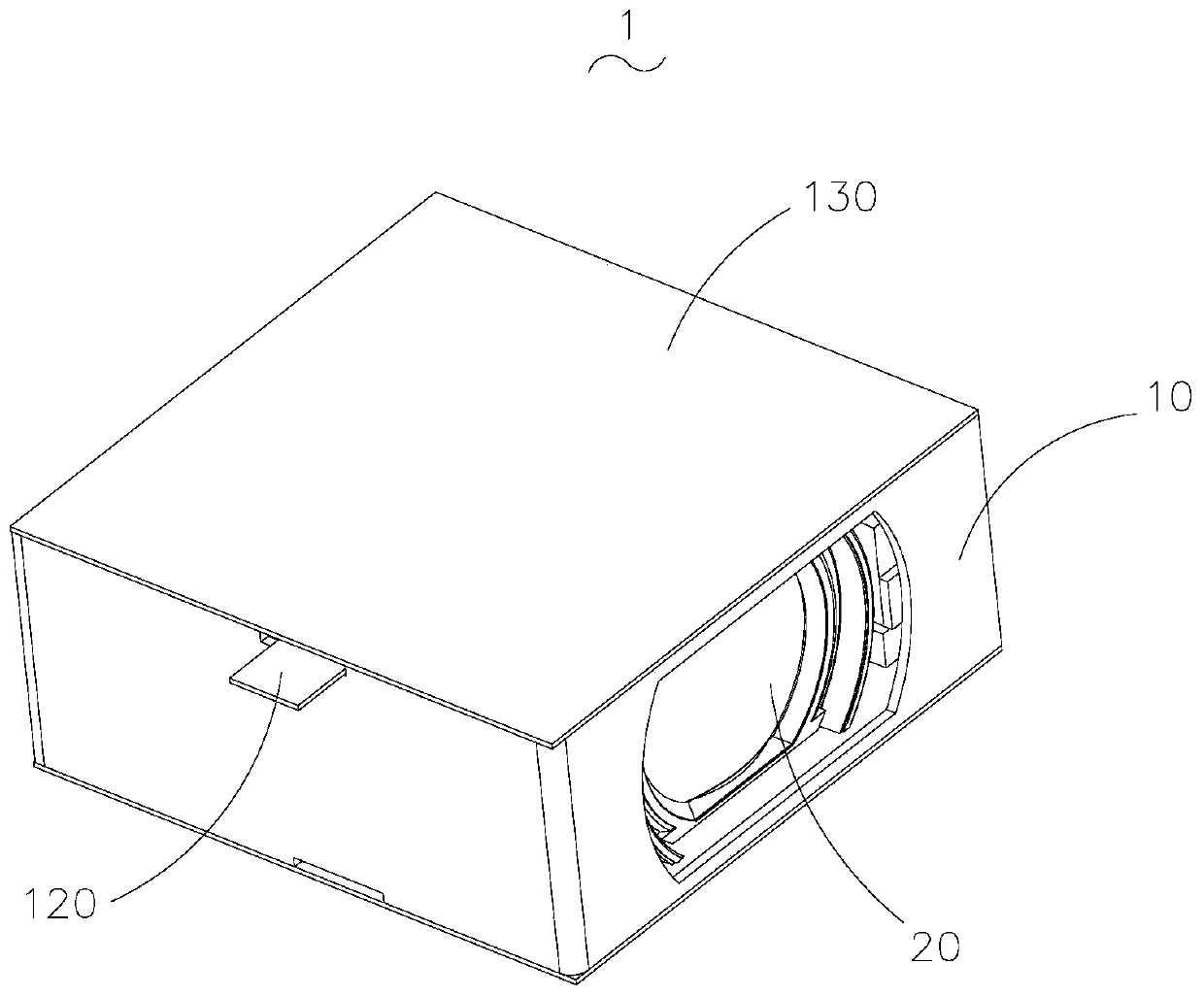

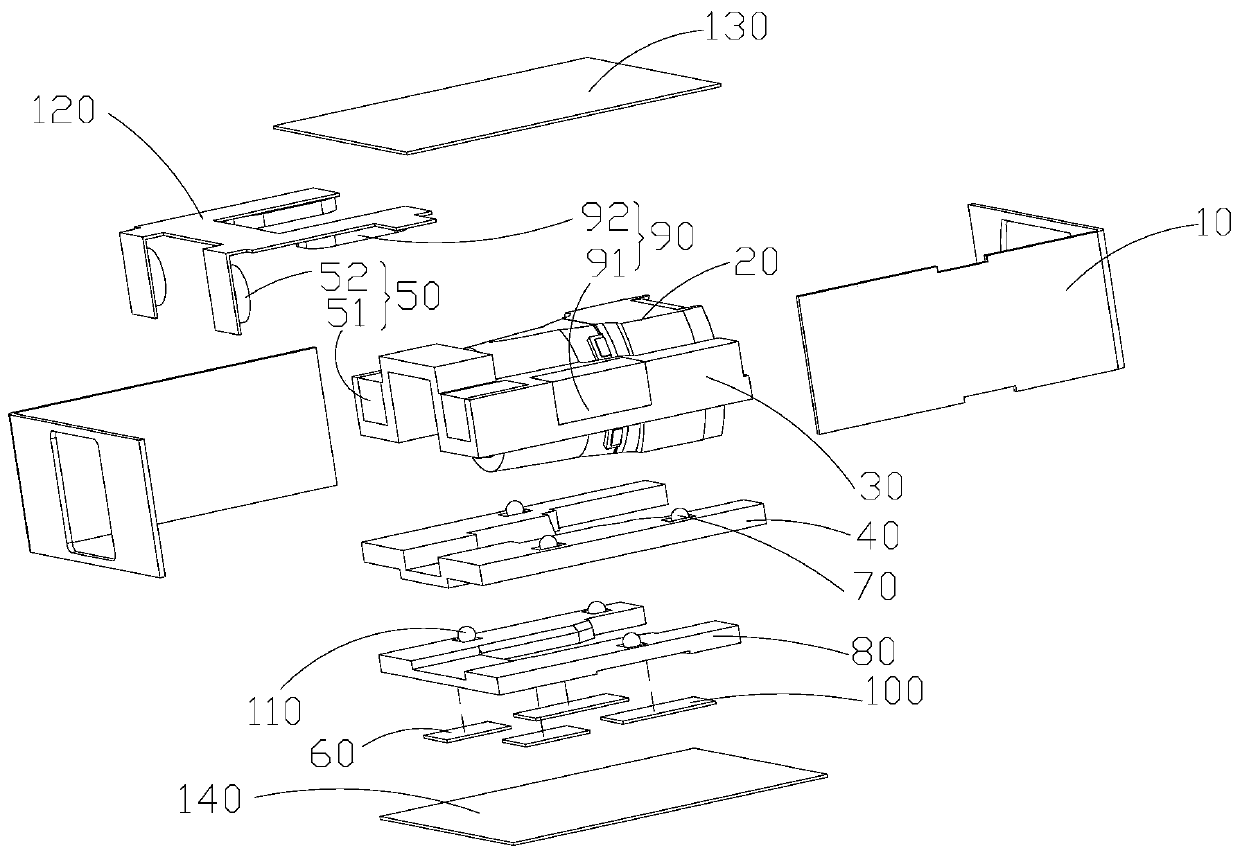

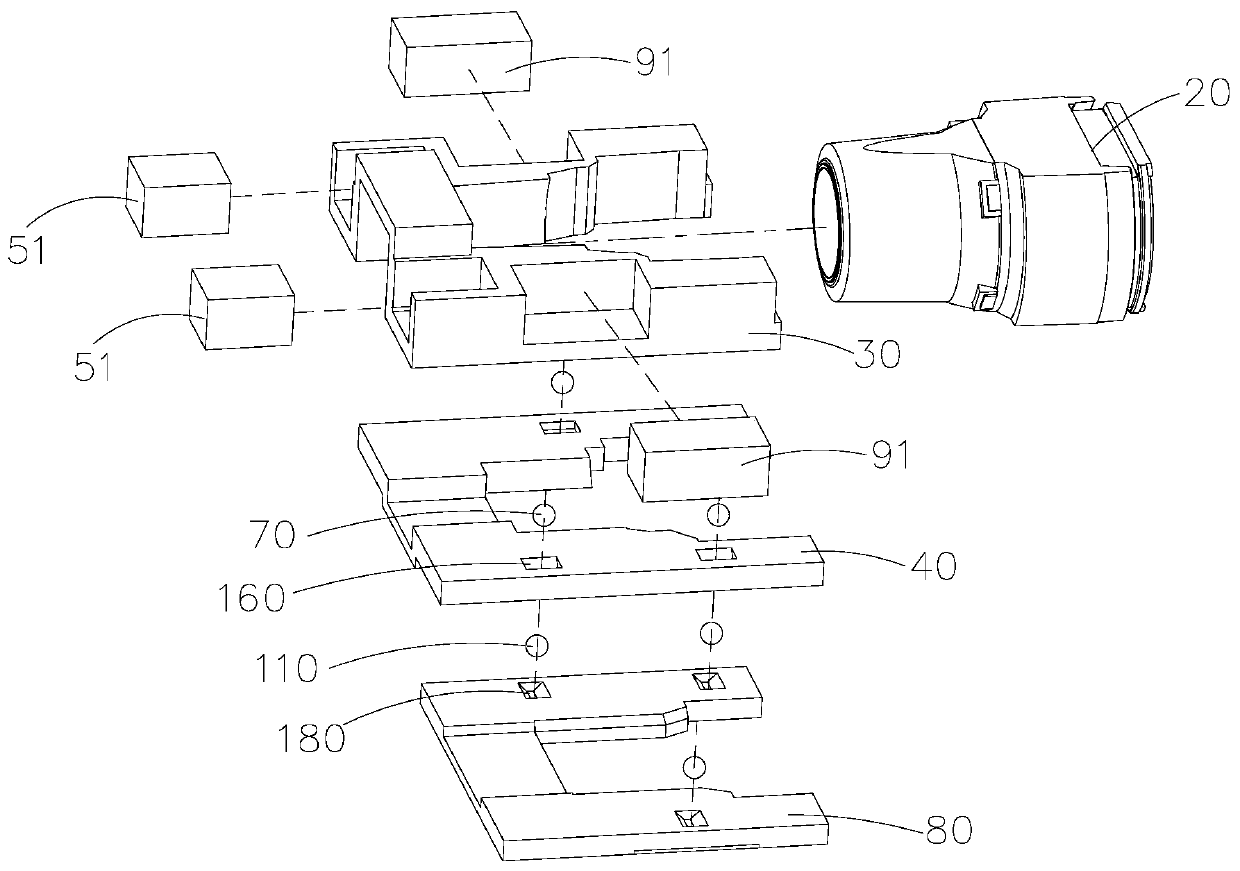

[0032] see Figure 1-7 , the first embodiment of the present invention relates to a lens module 1, comprising a housing, a lens 20 accommodated in the housing, a mounting bracket 30 for fixing the lens 20, a first base 40 opposite to the mounting bracket 30, a second Two bases 80, drive the mounting bracket 30 so that the lens 20 is relatively displaced relative to the first base 40 in the direction of the optical axis of the lens 20, and drive the mounting bracket 30 so that the lens 20 is relatively displaced relative to the second base 80 The relative displacement of the second driving member 90 in the direction perpendicular to the optical axis of the lens 20 , the first base 40 and the second base 80 are fixed relative to the housing. Specifically, the mounting bracket 30, the first base 40, and the second base 80 may be in sliding contact, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com