Device for preventing shaking of main rope for elevator

A main rope and anti-vibration technology, which is applied in the direction of transportation and packaging, elevators, etc., can solve problems such as elevator operation obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

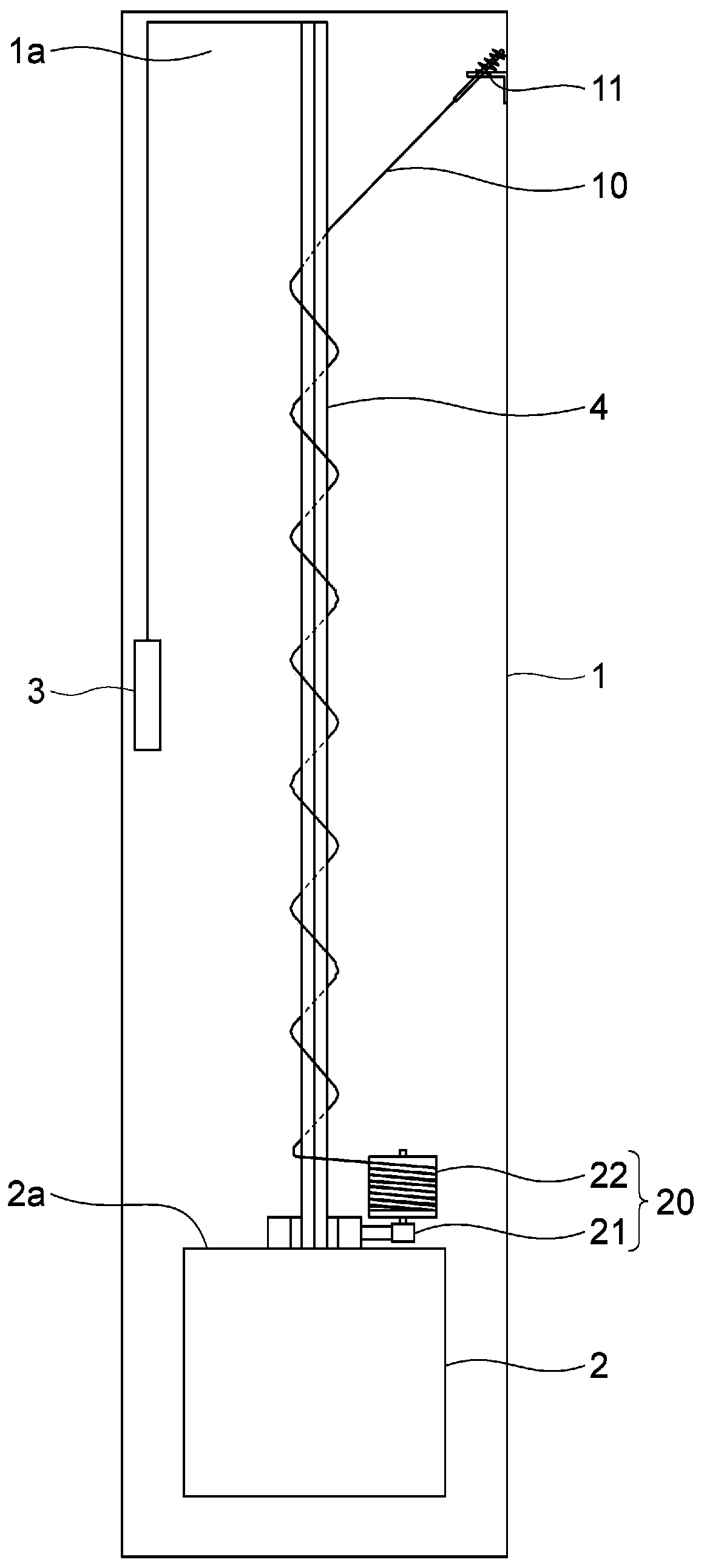

[0030] figure 1 It is a front view of an elevator equipped with the main rope vibration damping device for an elevator according to Embodiment 1 of the present invention.

[0031] like figure 1 As shown, one end of the three main ropes 4 is fixed to the car 2 which is installed in the hoistway 1 in a freely ascending and descending manner. The other end of the main rope 4 is fixed to the counterweight 3 . The car 2 constitutes a lifting body.

[0032] Around the main rope 4, a vibration damping rope 10 as a main rope vibration damping rope is provided. One end of the anti-vibration rope 10 is fixed to a rope fixing tool 11 provided on the ceiling 1 a of the hoistway 1 .

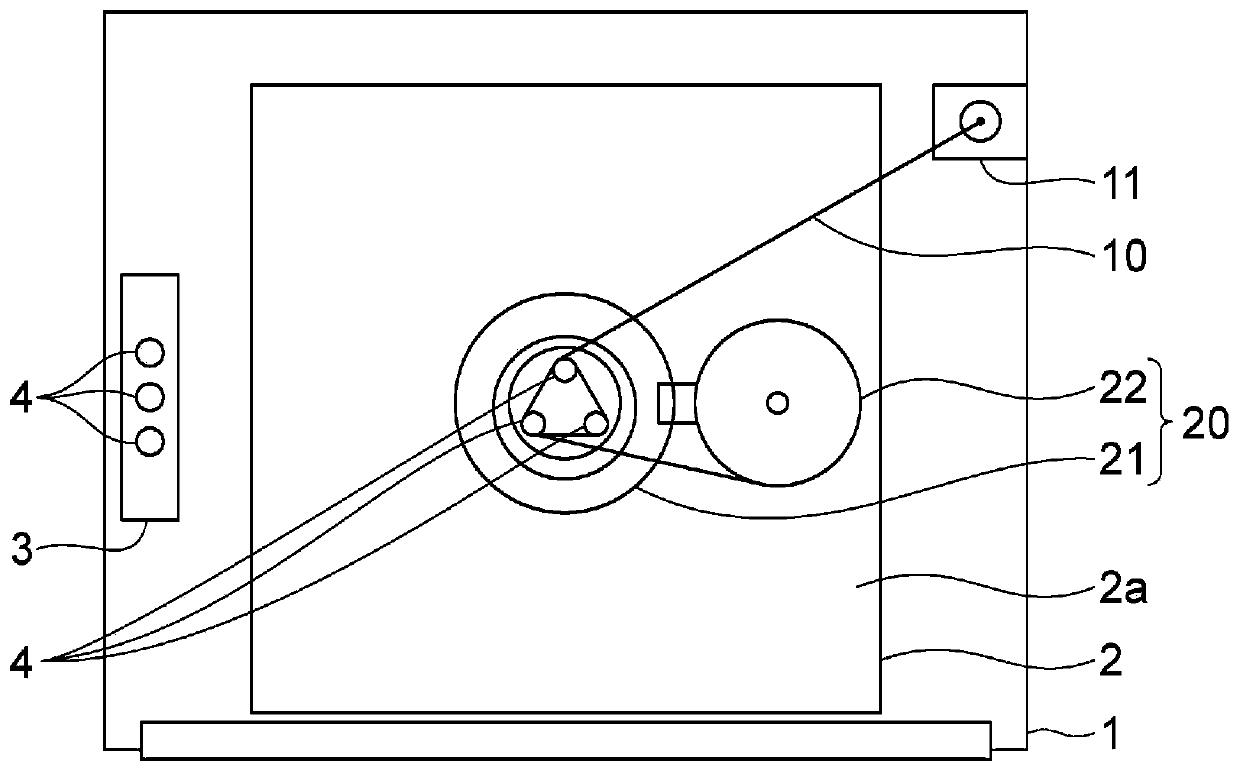

[0033] figure 2 Yes figure 1 A top view of the elevator shown. like figure 2 As shown, a disc-shaped rotating body 21 is provided on the upper portion 2 a of the car 2 so as to surround the main rope 4 . A motor (not shown) as a rotating body drive unit is attached to the rotating body 21 . The ro...

Embodiment approach 2

[0046] Next, use Figure 5 and Image 6 , the main rope vibration damping device for an elevator according to Embodiment 2 will be described. In Embodiment 2, the vibration-damping rope winds the auxiliary rope together with the main rope.

[0047] Figure 5 It is a front view of an elevator equipped with a main rope vibration damping device for an elevator according to Embodiment 2. like Figure 5 As shown, a rotating body 23 is provided on the upper part 2a of the car 2 . The rotating body 23 is rotated by an unillustrated motor as a rotating body drive unit. The drum 22 is provided on the rotating body 23 . The other end of the anti-vibration rope 10 is fixed to the drum 22 .

[0048] In the hoistway 1 , an auxiliary rope 30 is provided separately from the main rope 4 . One end of the auxiliary rope 30 is fixed to a rope fixing member 31 provided on the ceiling 1 a of the hoistway 1 . In addition, the other end of the auxiliary rope 30 is fixed to a rope fixing mem...

Embodiment approach 3

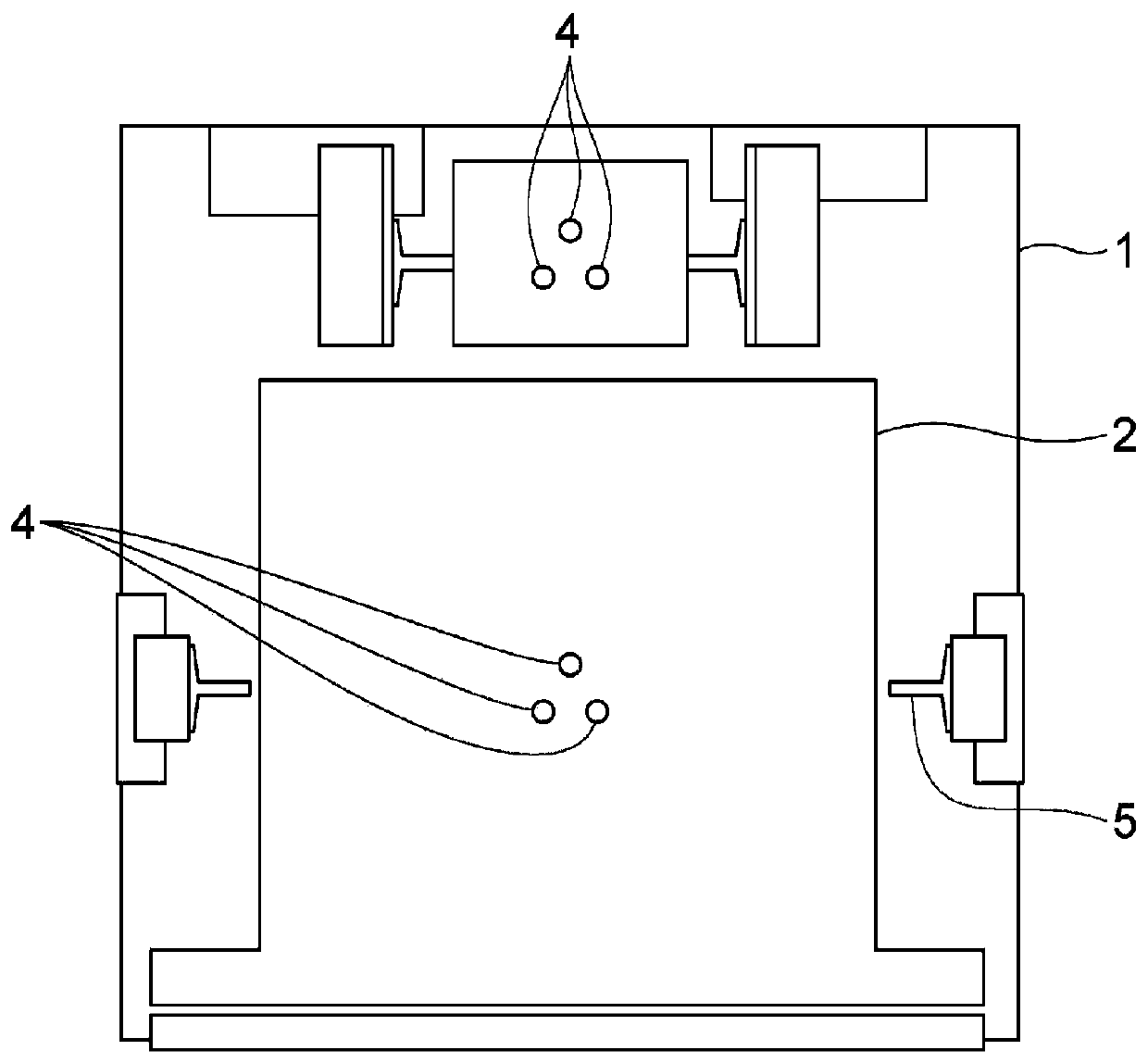

[0055] Next, use Figure 7 to Figure 9 , a main rope vibration damping device for an elevator according to Embodiment 3 will be described. In Embodiment 3, instead of the reel used in Embodiments 1 and 2, pulleys are used.

[0056] Figure 7 It is a front view of an elevator equipped with a main rope vibration damping device for an elevator according to Embodiment 3. One end of the anti-vibration rope 10 is fixed to a rope fixing member 11 on the ceiling 1 a of the hoistway 1 . The anti-vibration rope 10 descends obliquely downward in the hoistway 1 while making one turn around the main rope 4 . A rotating body 24 is provided on the upper portion 2 a of the car 2 . A motor (not shown) as a rotating body drive unit is attached to the rotating body 24 . The rotating body 24 is controlled to rotate clockwise and counterclockwise by the rotation of the motor. On the outer peripheral side of the rotating body 24, a direction changing portion 24a that is a pulley provided in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com