Multi-stage resin surface etching method, and plating method on resin using same

A resin and etching technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of low adhesion, poor working environment, high cost, and achieve high adhesion and efficient etching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057]

[0058] A 50×100×3 mm ABS resin test piece (3001M: manufactured by UMGABS Co., Ltd.) was used as a sample. The sample was immersed in degreasing cleaning solution PC-1 and PC-2 (manufactured by JCU Co., Ltd.) at 60°C for 10 minutes, and then placed in a 50°C bath containing 10 ml / L of ENILEX WE (manufactured by JCU Co., Ltd.). Immerse in the surface conditioning solution for 10 minutes.

[0059] The sample subjected to degreasing and surface conditioning was treated by the etching process described in Table 1, and further immersed in a conditioning (catalyst imparting enhancement) treatment solution D-POP CDV (manufactured by JCU Corporation) at 25° C. for 1 minute.

[0060] In addition, the etchant used in the etching process described in Table 1 is as follows.

[0061] Chromate etching (existing method)

[0062] Chromic anhydride: 3.8mol / L

[0063] Sulfuric acid: 3.8mol / L

[0064] Liquid temperature 68°C

[0065] The method of the invention

[0066] Process (...

Embodiment 2

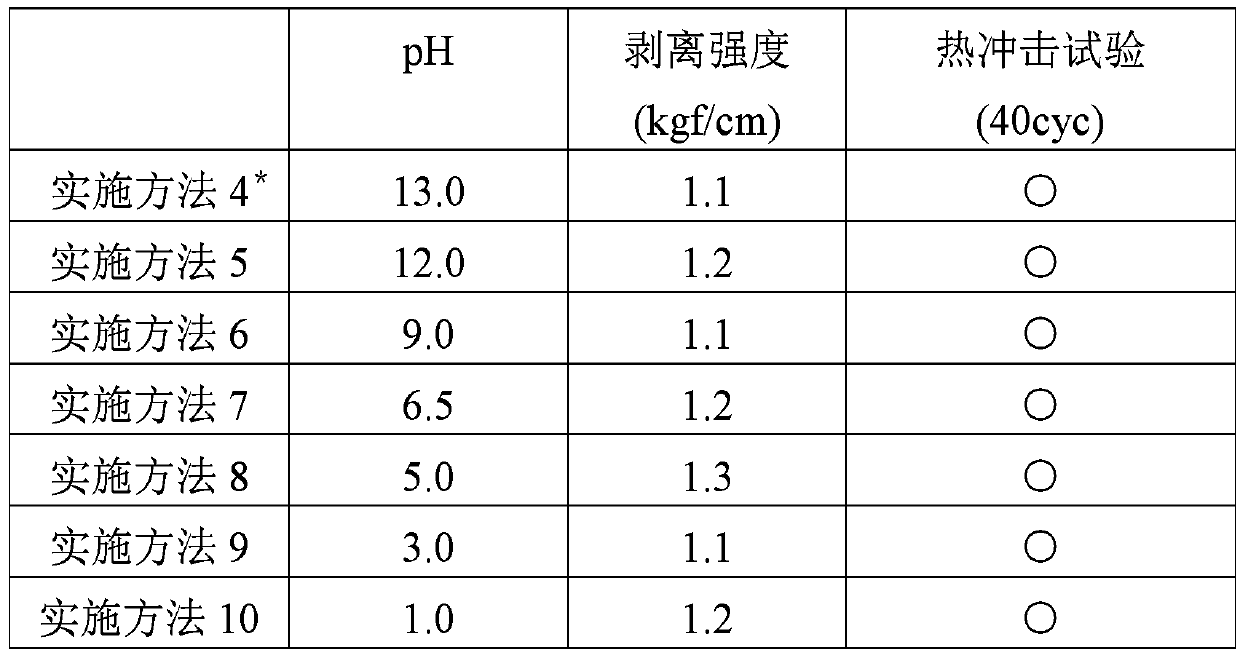

[0088] In the implementation method 1 of Example 1, the pH of the etching solution used in the step (a) is set to the value in Table 2, and the buffer solution in Table 3 is used as the pH buffer solution corresponding to the pH. In Example 1, electroless nickel plating was performed in the same manner. In addition, sodium hydroxide and sulfuric acid were used for pH adjustment. In addition, the electroless nickel plating layer was subjected to peel strength measurement and thermal shock test in the same manner as in Example 1. The results are shown in Table 2.

[0089] 【Table 2】

[0090]

[0091] * Carry out 5 sets of procedures (a) and (b)

[0092] 【table 3】

[0093] pH pH buffer 10.0 or above Carbonic acid / bicarbonate buffer 5.5~10.0 Boric acid / sodium tetraborate buffer 2.5~5.5 Acetic acid / sodium acetate buffer Below 2.5 Phosphate / sodium dihydrogen phosphate buffer

[0094] In the method of the present invention, any pH is no...

Embodiment 3

[0096] In implementation method 1 of Example 1, electroless nickel plating was performed similarly to Example 1 except having removed the pH buffering agent from the liquid used in process (a) and (b). When the peel strength measurement and the thermal shock test were performed on this electroless nickel plating layer in the same manner as in Example 1, the results were the same as in Embodiment Method 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com