Drilling machine for wood

A drilling machine, wood technology, applied in wood processing equipment, fixed drilling machine, bark area/debris/dust/waste removal, etc., can solve easy residual wood chips, drill blockage, uneven laying level, etc. problem, to achieve the effect of flexible compaction treatment, preventing clogging and preventing splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

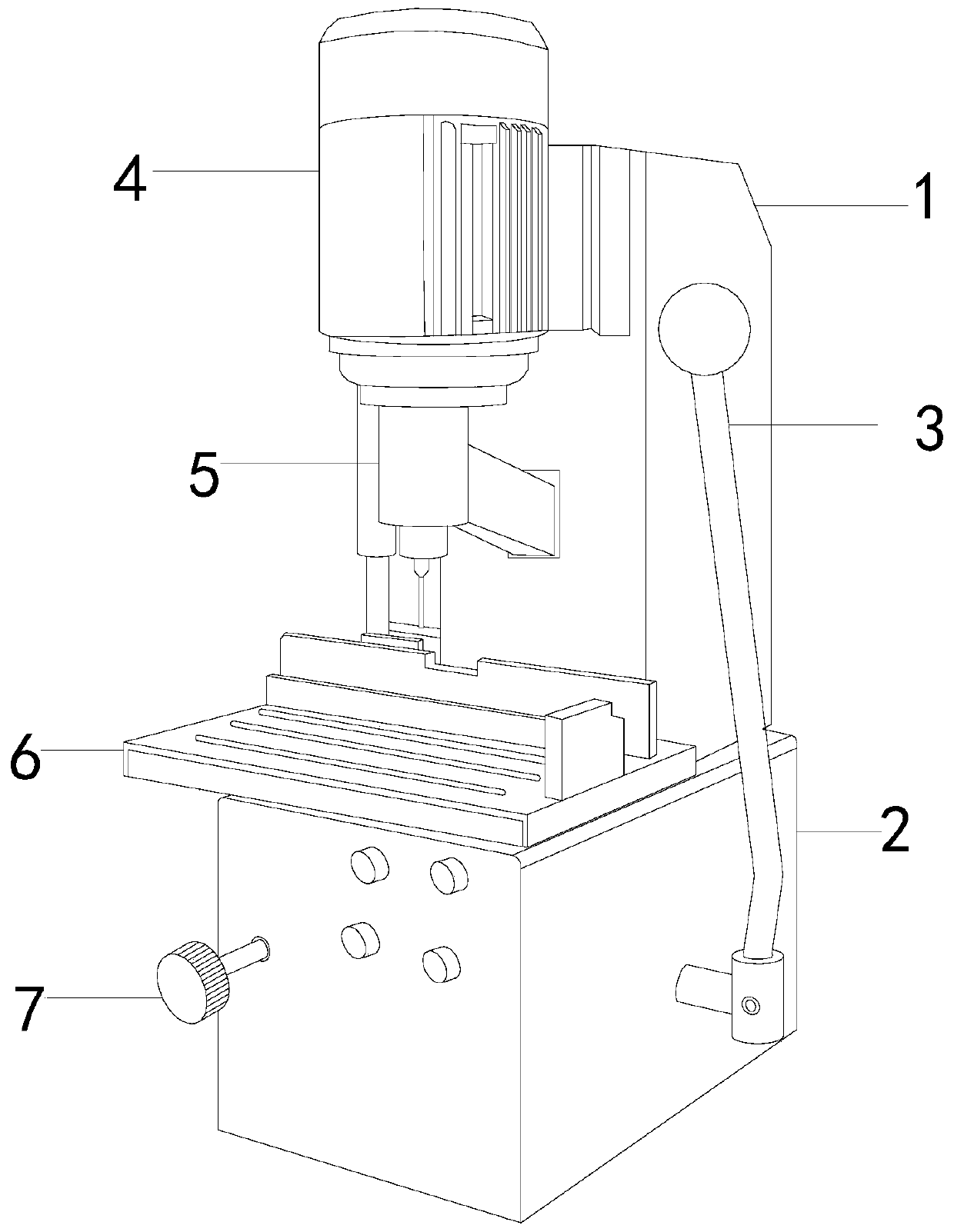

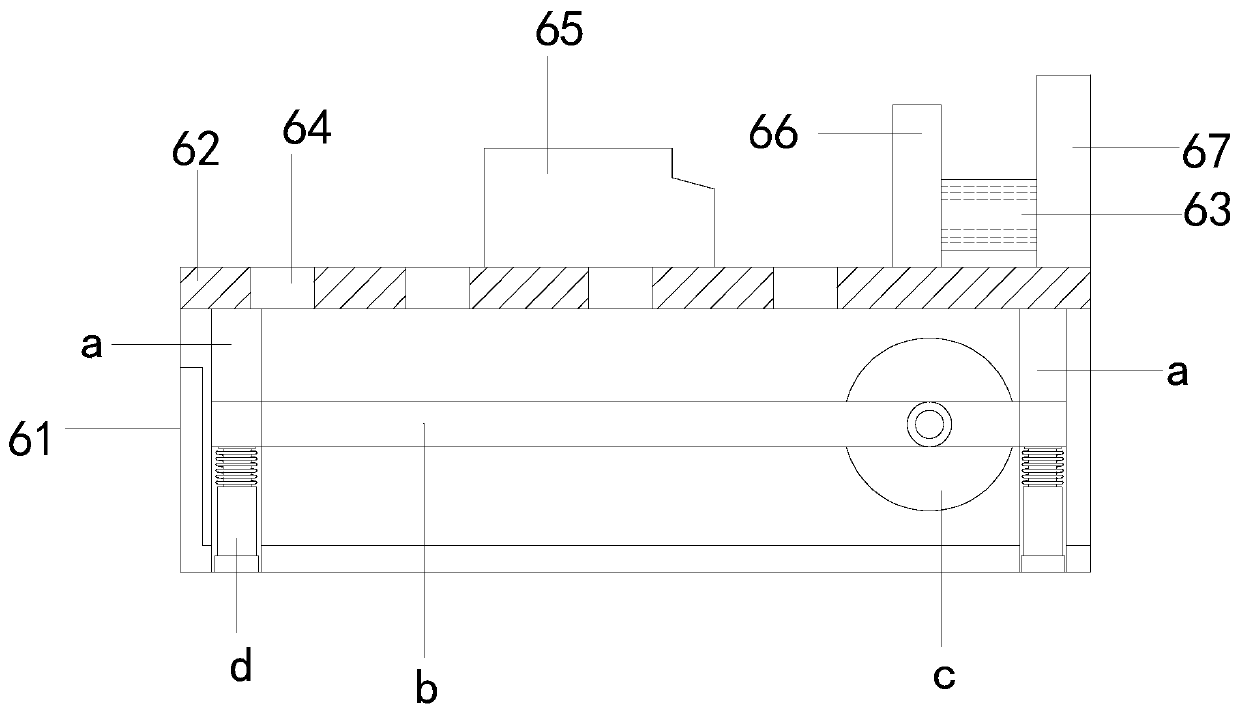

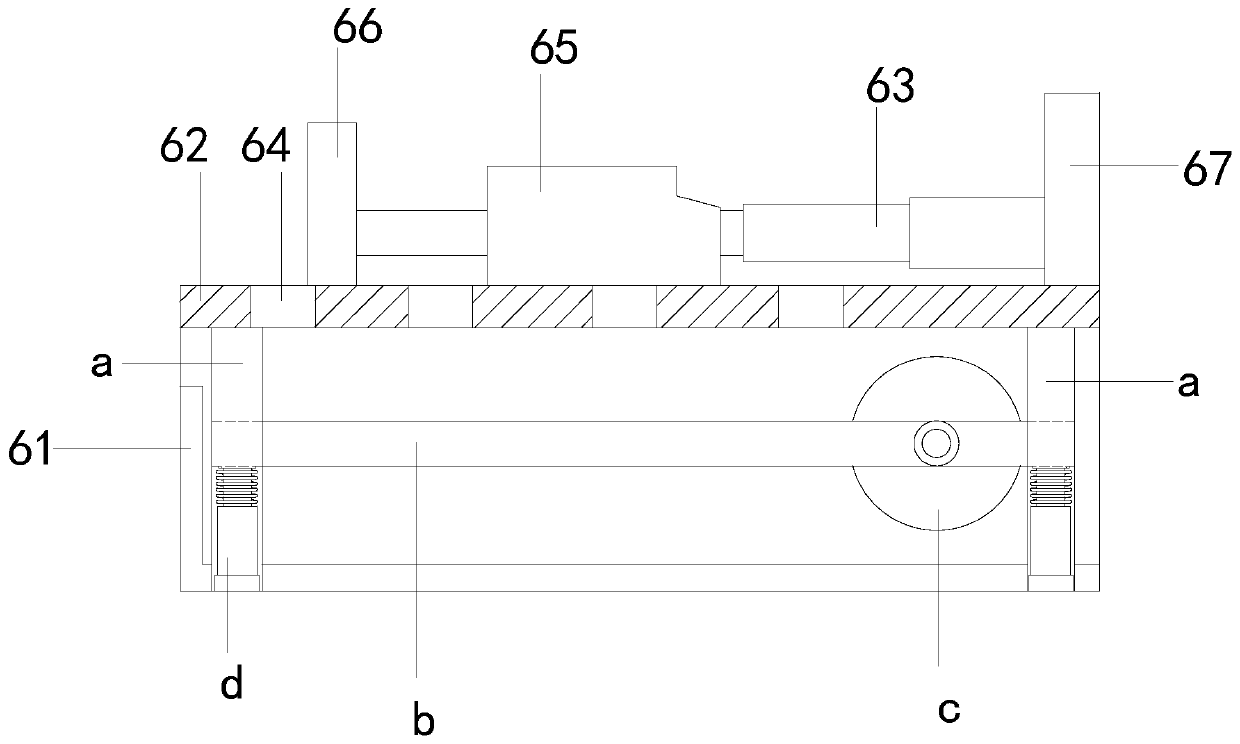

[0023] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of wood drilling machine, and its structure comprises frame 1, cabinet 2, control bar 3, motor 4, drill 5, processing table 6, adjuster 7, described frame 1 and The fixed connection of the chassis 2, the control rod 3 is connected with the chassis 2, the motor 4 is fixed above the front end of the frame 1, the drill 5 is connected below the motor 4, and the processing table 6 is fixed on The upper end of the cabinet 2, the cabinet 2 is provided with a regulator 7, and the processing table 6 is mainly composed of a storage base 61, an electromagnetic board 62, a telescopic push rod 63, a discharge channel 64, a top plate 65, a pusher plate 66, Support plate 67, the electromagnetic plate 62 is fixed at the upper end position of the storage base 61, the support plate 67 is fixed at the upper rear end position of the electromagnetic plate 62, and the pushing plate 66 is fixed with the support plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com