Assembled prestressed ultra-high-strength steel-self-stressed fiber reinforced concrete protective door

A fiber-reinforced concrete and self-stressing technology, which is applied in door leaf, window/door, anti-war damage, etc., can solve the problems of increasing the risk of exposure of protective works, high requirements for construction standards of foundation parts, and increased weight of concrete used in steel materials, etc., to achieve The construction quality is easy to guarantee, the difficulty of maintenance and reinforcement is reduced, and the construction speed is accelerated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

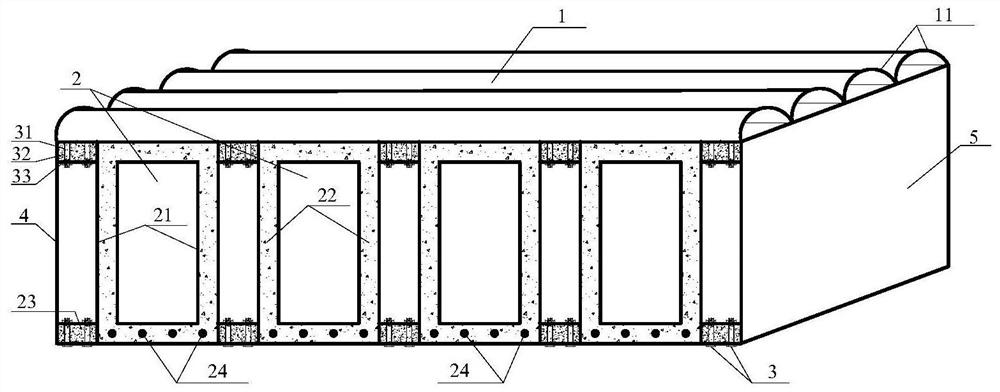

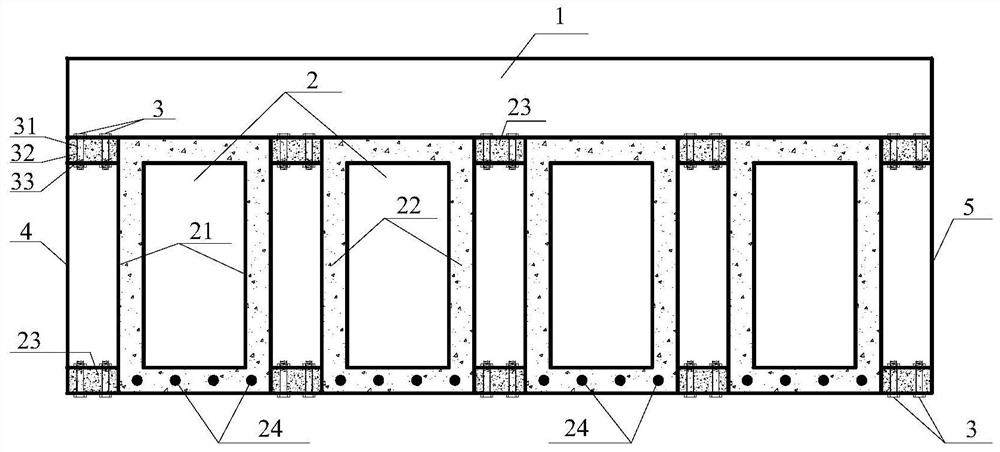

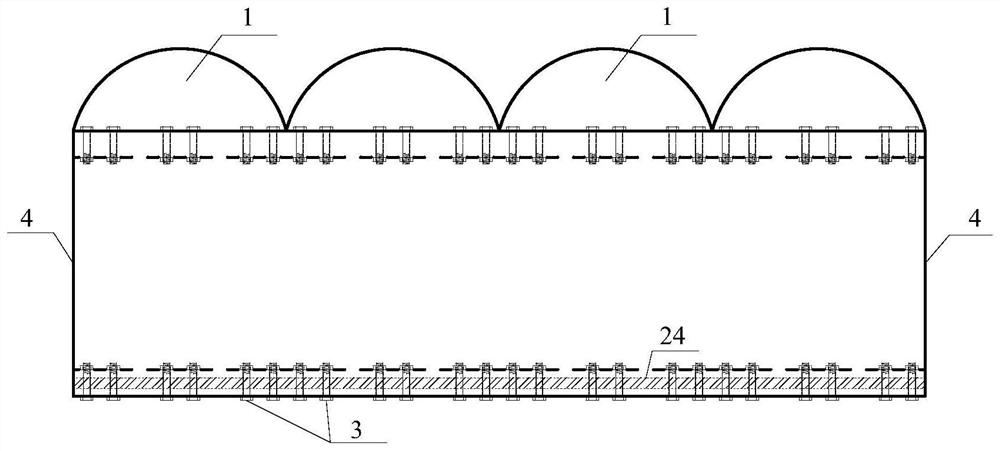

[0035] Such as figure 1 , 2 , 3, and 4, the assembled prestressed ultra-high-strength steel-self-stress fiber concrete protection door of the present invention includes arc energy dissipation device 1, ultra-high-strength steel-self-stress fiber concrete main beam 2 and left and right ultra-high-strength steel Side block 4, 5;

[0036] The arc-shaped energy dissipation device 1 is detachably fixedly connected to the top of the ultra-high-strength section steel-self-stressing fiber concrete main beam 2 through an assembly connector 3, and the left and right ultra-high-strength section steel side blocks 4, 5 are respectively connected to the ultra-high-strength section steel - The left and right sides of the self-stressing fiber reinforced concrete girder 2 are detachably fixedly connected by assembly connectors 3;

[0037] The arc-shaped energy dissipation device 1 and the left and right ultra-high-strength steel side blocks 4, 5 are all prefabricated by ultra-high-strength ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com