Fire extinguisher valve

A technology for fire extinguishers and valves, which is applied in the direction of valve lifts, valve details, valve devices, etc., and can solve the problem that fire extinguishers are not suitable for people with small hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

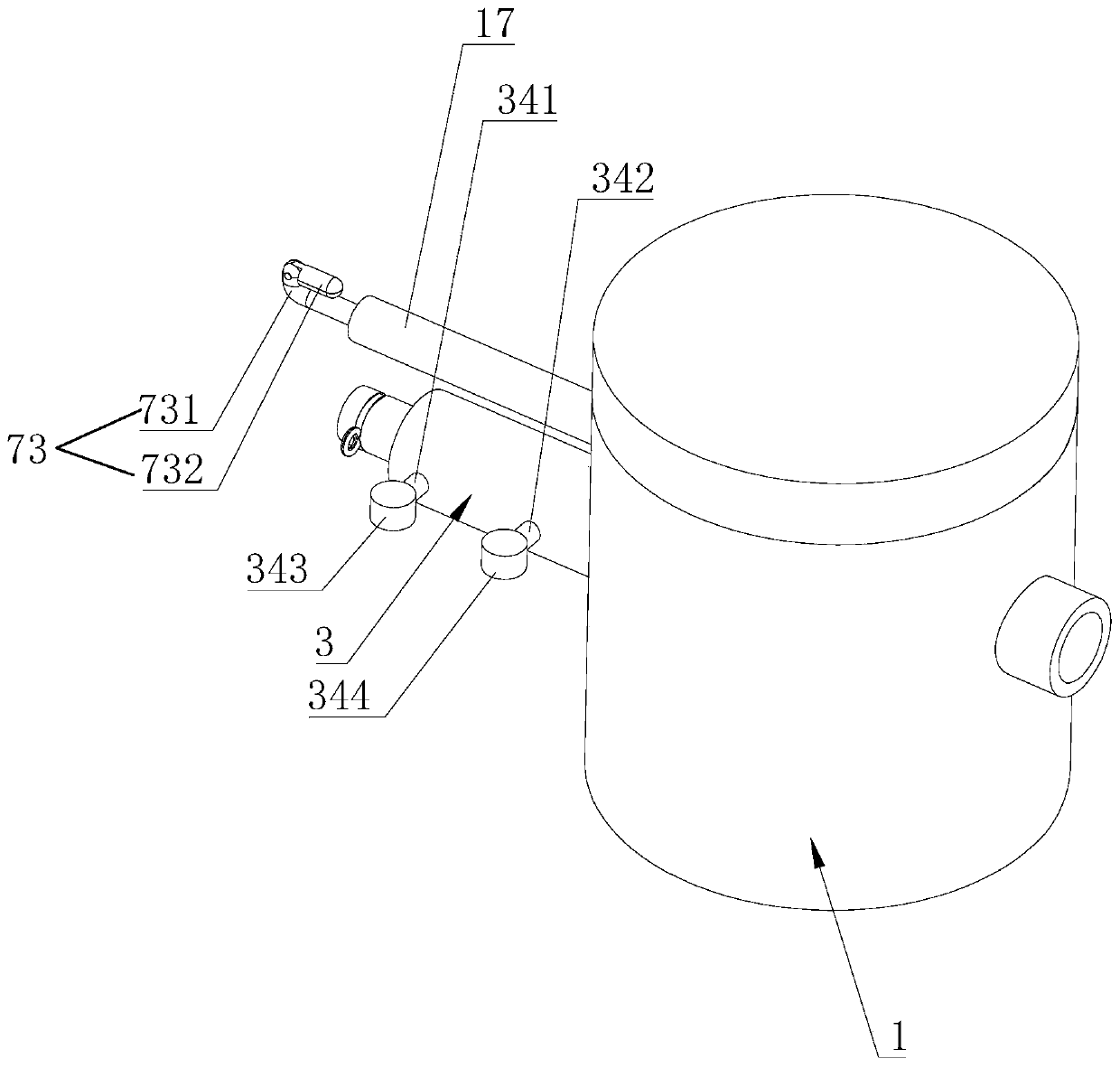

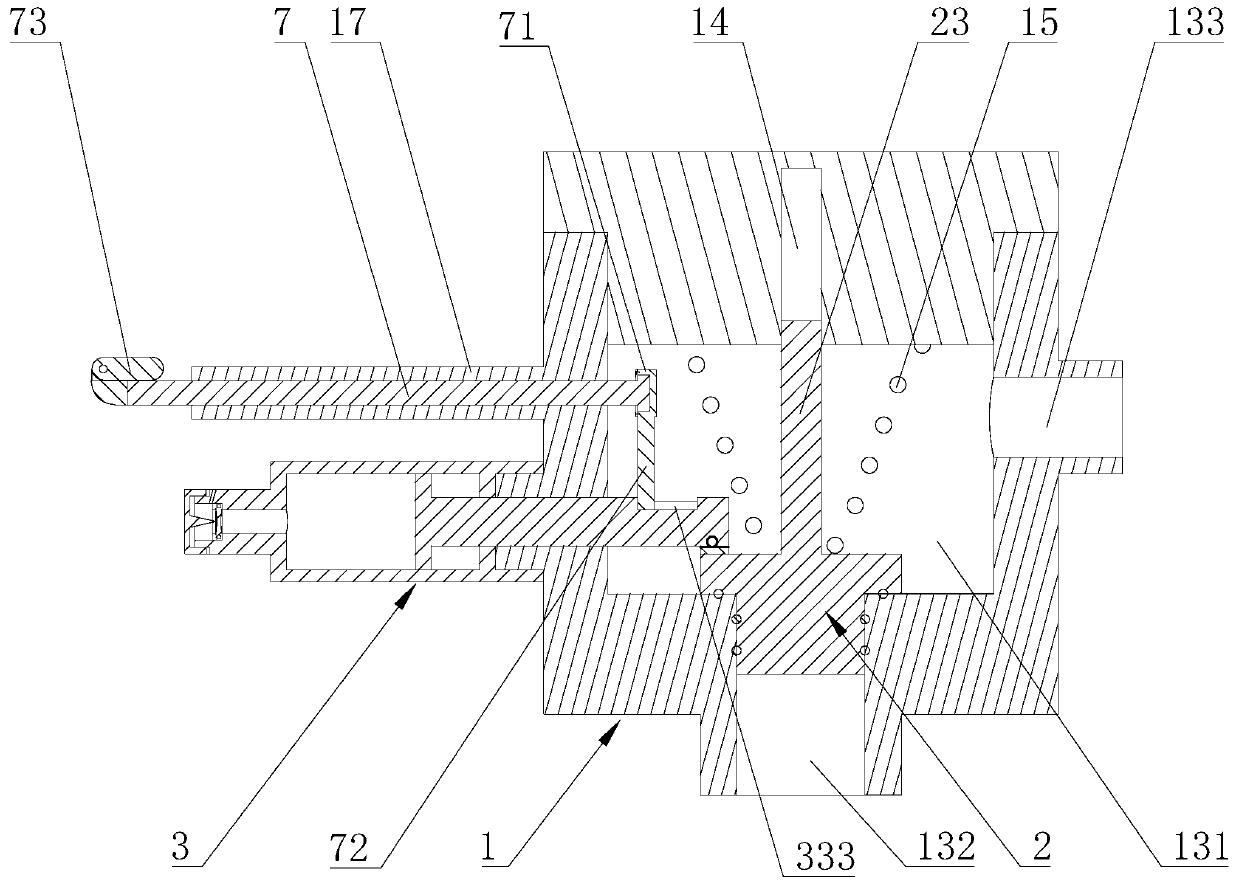

[0043] See attached figure 1 And attached figure 2 , a fire extinguisher valve mainly includes a valve body 1, a valve core 2 and a locking cylinder 3.

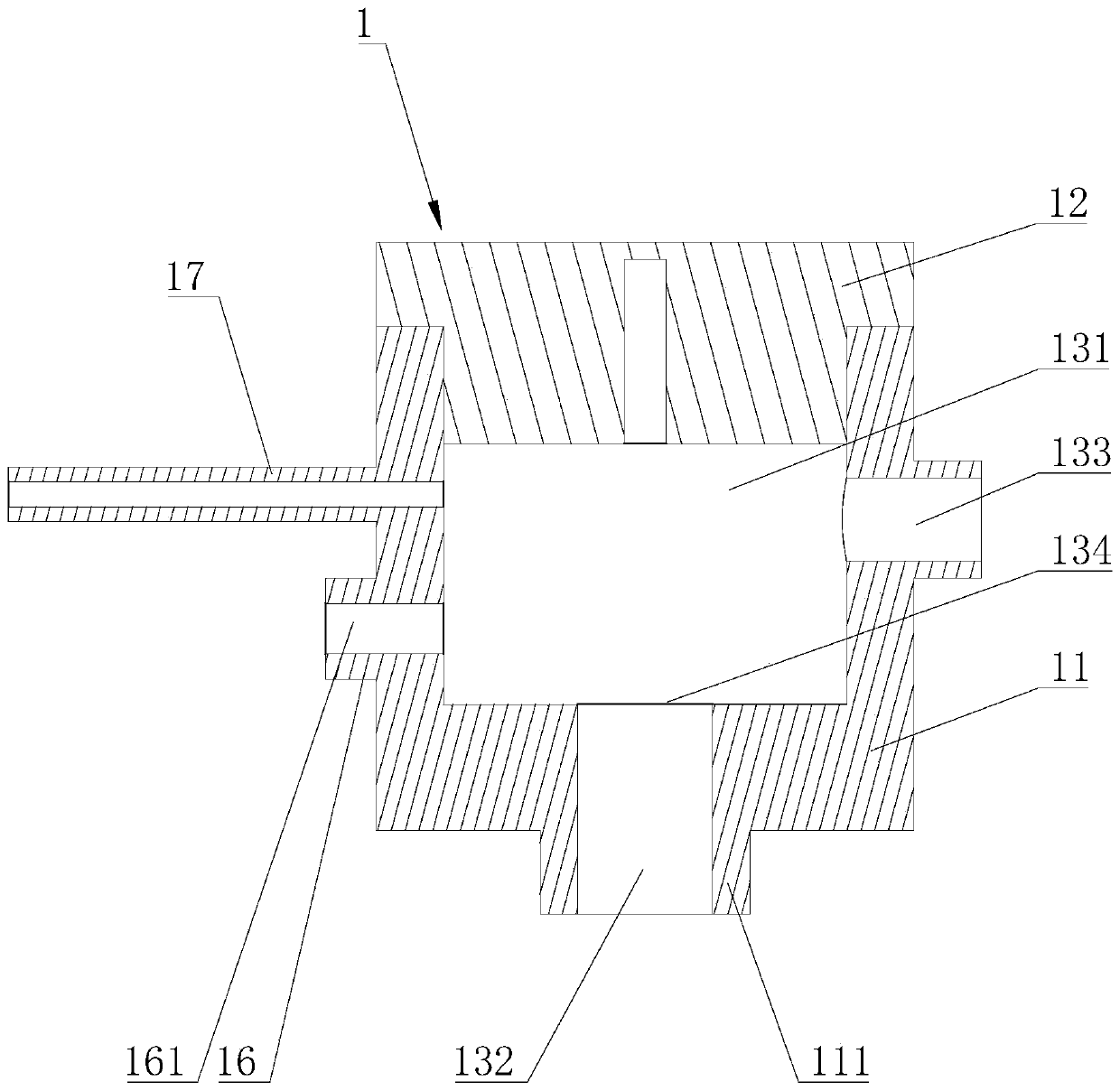

[0044] See attached image 3 , The valve body 1 includes a lower valve body 11 and an upper valve body 12 . The top of the lower valve body 11 is provided with a counterbore, and the side wall of the lower valve body 11 is also provided with a side hole communicated with the counterbore and arranged horizontally. The upper valve body 12 is threadedly mounted on the top of the lower valve body 11 , and seals and covers the top opening of the counterbore in the lower valve body 11 . When the upper valve body 12 is installed on the lower valve body 11 to form the valve body 1 , the counterbore and the side hole are combined to form the control chamber 131 , the first flow channel 132 and the second flow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com