Method for implementing large interlocking test function group configuration based on GB assembly language of Ovation

An assembly language, interlocking test technology, applied in instruments, simulators, control/regulation systems, etc., can solve the problems of reduced logical readability, easy execution errors, and damage to the logical layout, shortening the summarization time, and improving work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

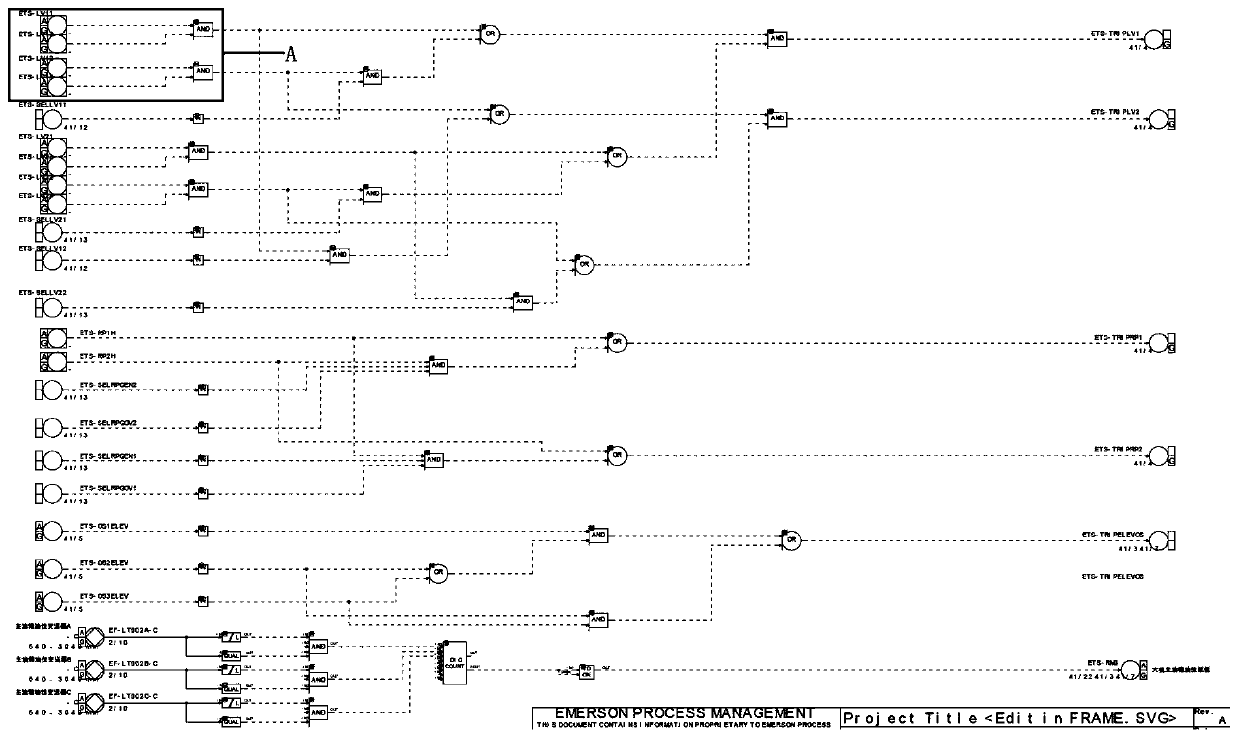

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

[0034] The purpose of large interlocking: the boiler, steam turbine, and generator of the unit have their own protection systems, and the action of any part of the protection system will affect the safe operation of other parts. At present, the unit has gradually developed into a relatively complete logic system. Judgment and control functions are processed by a special device, which is the large interlock protection system of the unit unit.

[0035] The large interlock protection test needs to be carried out before each ignition of the unit. The purpose is to verify the correctness of the logic and wiring of the interlock protection circuit between the three main engines, and to ensure the safety of the unit and equipment.

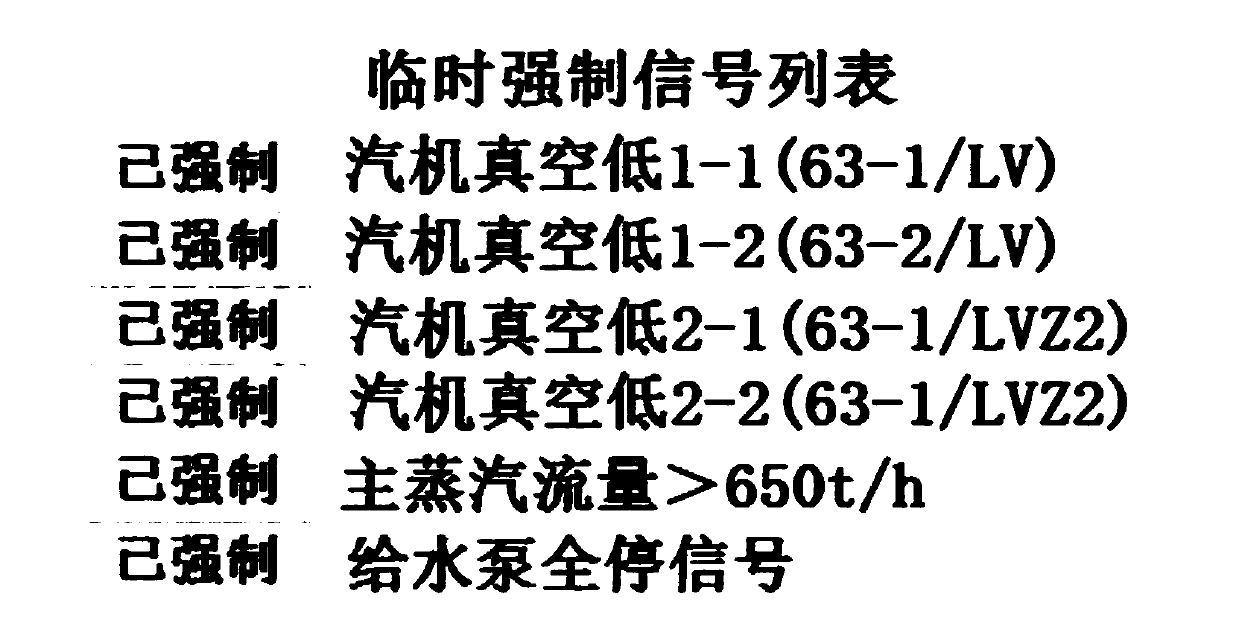

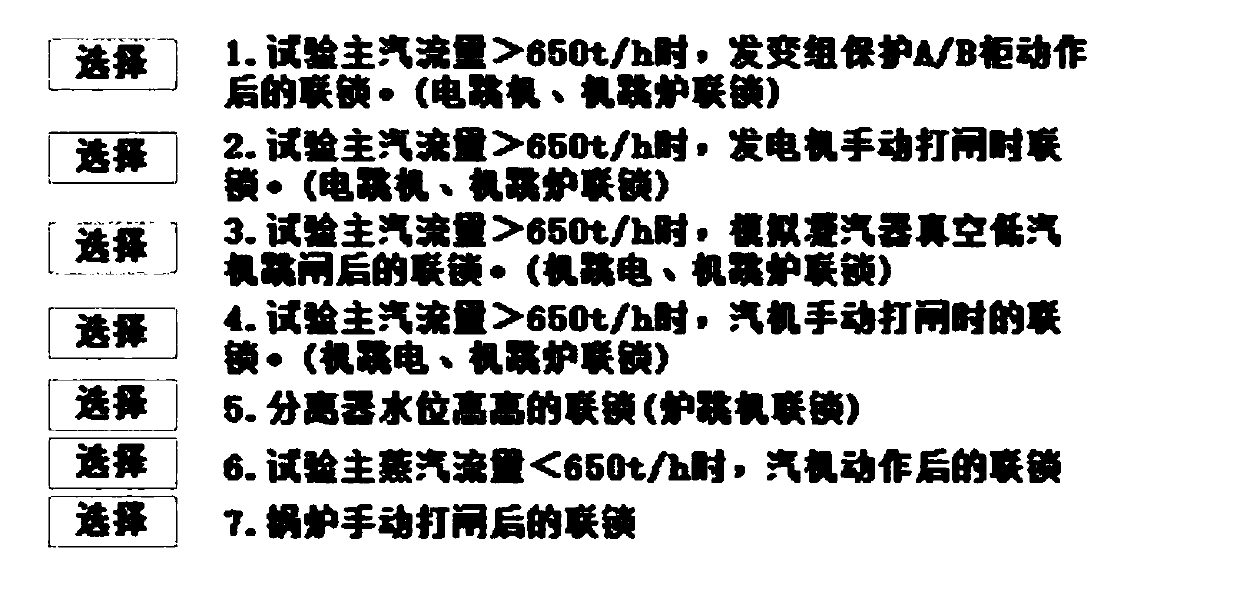

[0036] as attached figure 1 And attached figure 2 , based on Ovation's GB assembly language to realize the method of large interlocking test f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com