A Pre-storage Reactivity Control Mechanism

A technology of reactivity control and energy storage mechanism, which is applied in the direction of reactors, nuclear power generation, climate sustainability, etc., can solve the problems of increasing the volume of the core and shielding body, affecting the small and light weight of the reactor, and increasing the size of the reflective layer. Achieve less reactivity, achieve reliability, and achieve the effect of small equivalent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

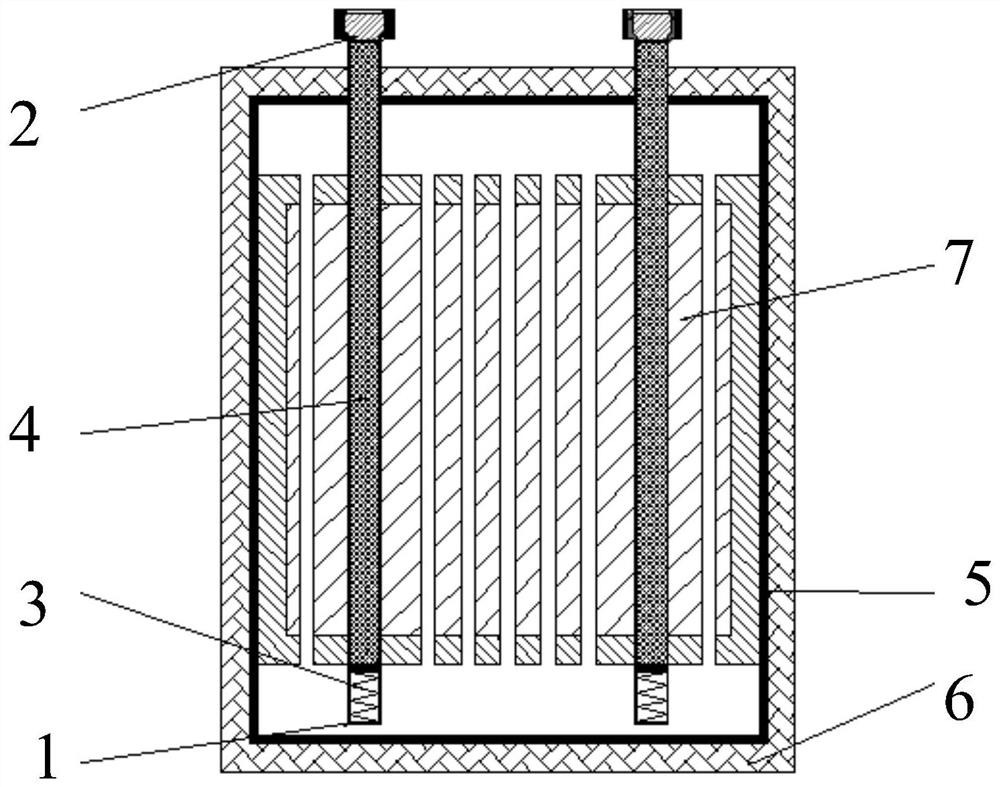

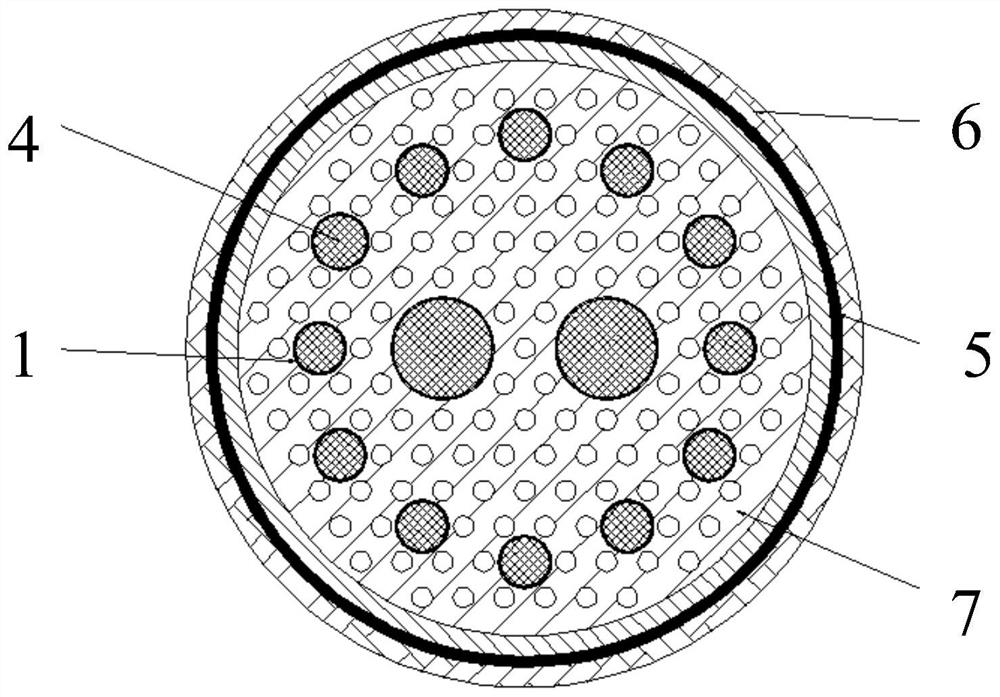

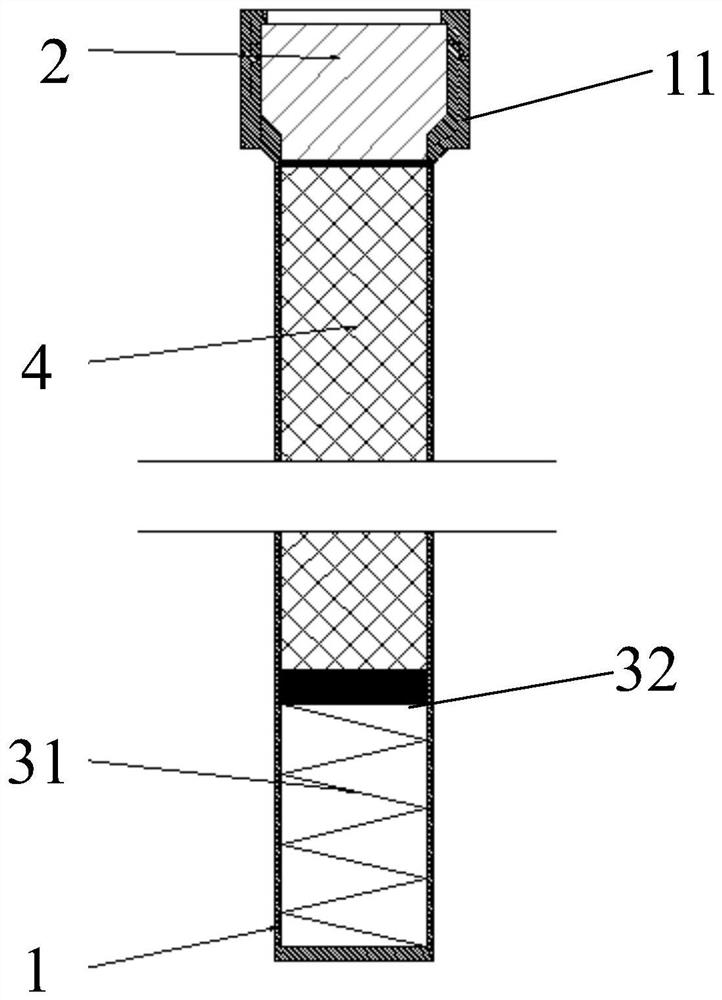

[0032] Such as Figure 1-3 As shown, a pre-storage reactive control mechanism of this embodiment includes an outer tube 1 and a solidification seal 2 packaged in the inner chamber of the outer tube 1, an energy storage mechanism 3 and a reactive element 4; wherein, the outer tube 1 The top nozzle of the tube is exposed outside the reactor vessel 5 of the nuclear reactor, and the outer tube 1 body is vertically inserted into the reactor vessel 5 .

[0033] The outer tube 1 is the boundary of the pre-storage reactivity control mechanism, providing isolation from the reactor environment. The outer tube 1 is specifically a cylindrical shell structure with a head at the bottom, which adopts multi-section welding, and a boss 11 is formed at the nozzle of the top, and the solidification seal 2 is arranged in the boss 11 .

[0034] The solidification seal 2 is the control element of the pre-storage energy reactivity control mechanism. The solidification seal 2 is arranged on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com