Chopping control system of traction inverter

A traction inverter, control system technology, applied in control systems, control/regulation systems, AC motor control, etc. Stability and other problems, to achieve the effect of high integration, solving voltage instability, and solving poor real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

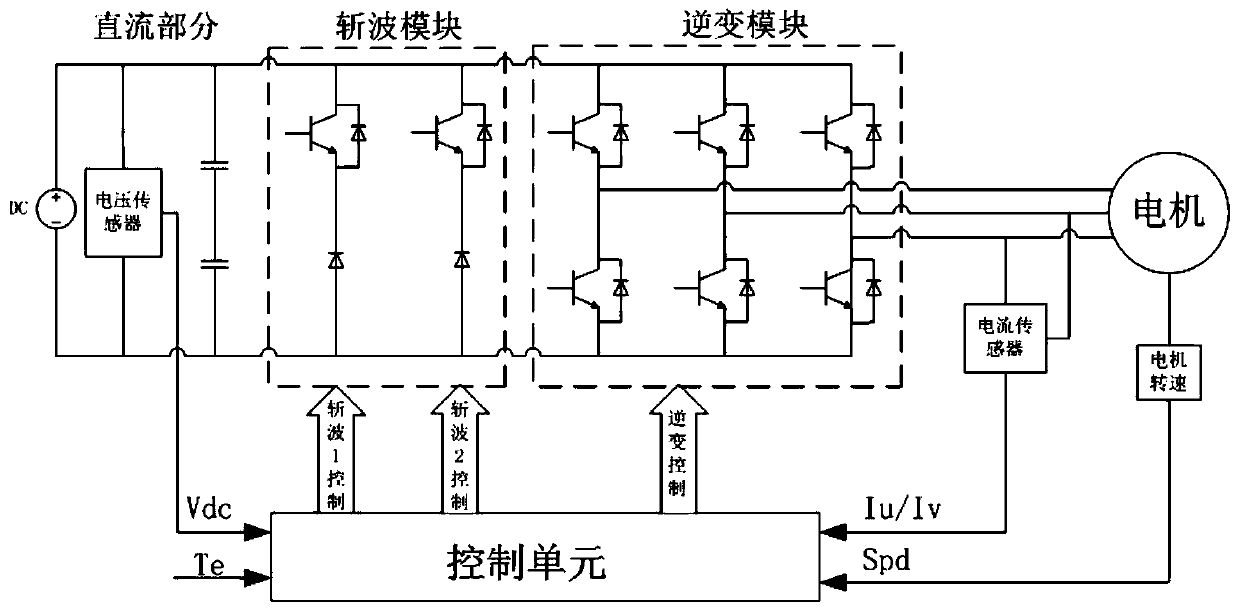

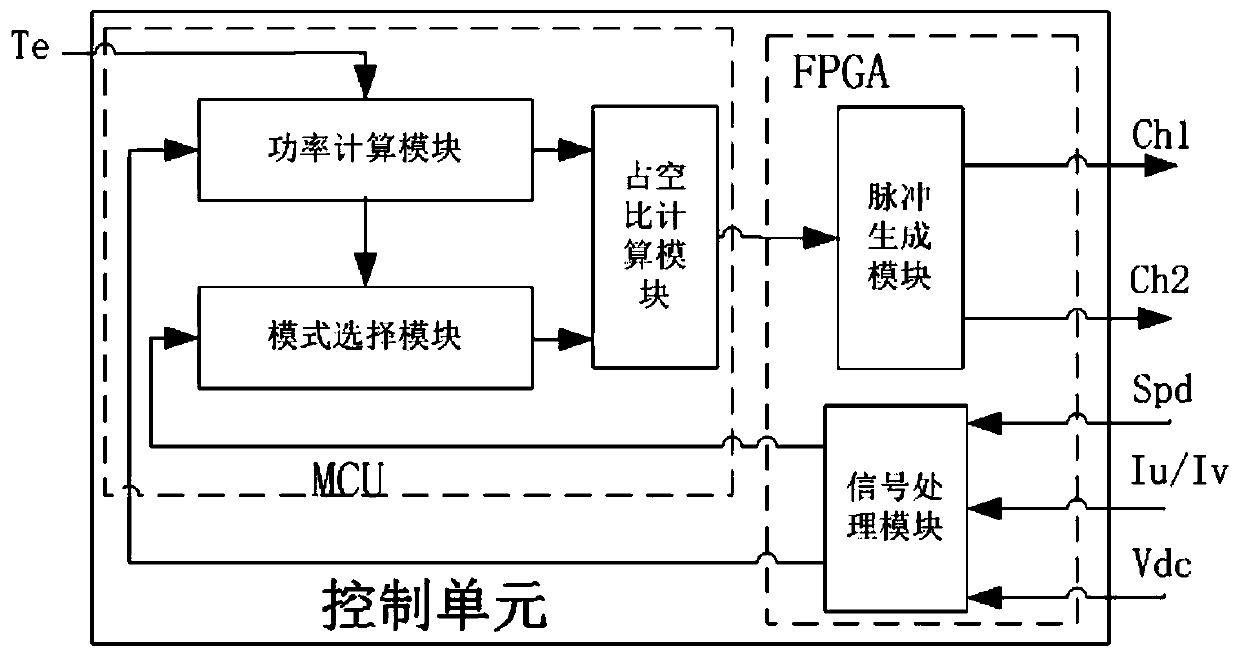

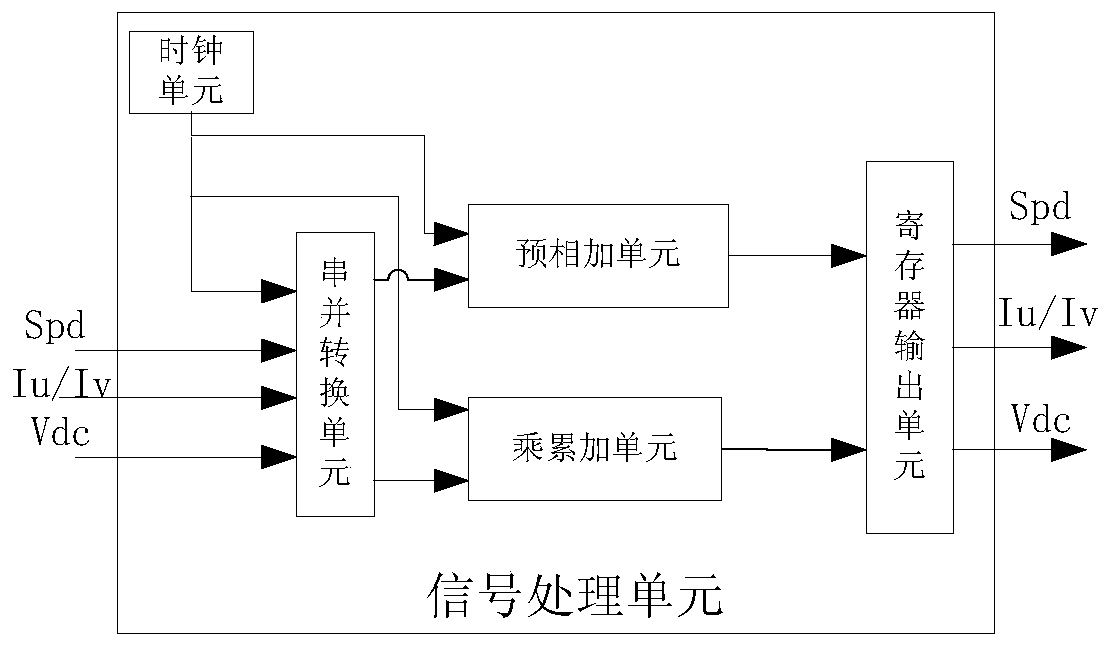

[0017] refer to figure 1 , the traction inverter includes a DC part, a chopping part, and an inverter part. The control unit sends a PWM signal through an external input analog signal (voltage Vdc, torque Te, speed Spd, current Iu / Iv) through internal processing and calculation. Pulse signal (chopping 1 control, chopping 2 control and inverter control), and then control the opening and closing of IGBT to realize chopping control and inverter control. The control unit of the present invention is actually a part of the traction inverter control system (motor control system), which mainly includes a double-bridge IGBT chopper unit and a control unit to realize the traction inverter chopper control under motor braking conditions and solve the problem of reducing The calorific value of the single-bridge IGBT improves the real-time performance of the chopper control, stabilizes the intermediate voltage, and facilitates the implementation of the overall control system of the traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com