Rotating bed with concentric corrugated rings

A technology of corrugated rings and rotating beds, applied in chemical methods for reacting liquid and gaseous media, chemical/physical/physicochemical fixed reactors, chemical/physical/physicochemical processes, etc., capable of solving limitations, rotating beds To solve the problem of low mass transfer efficiency and achieve the effect of improving the circumferential distribution of liquid and improving the efficiency of gas-liquid mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

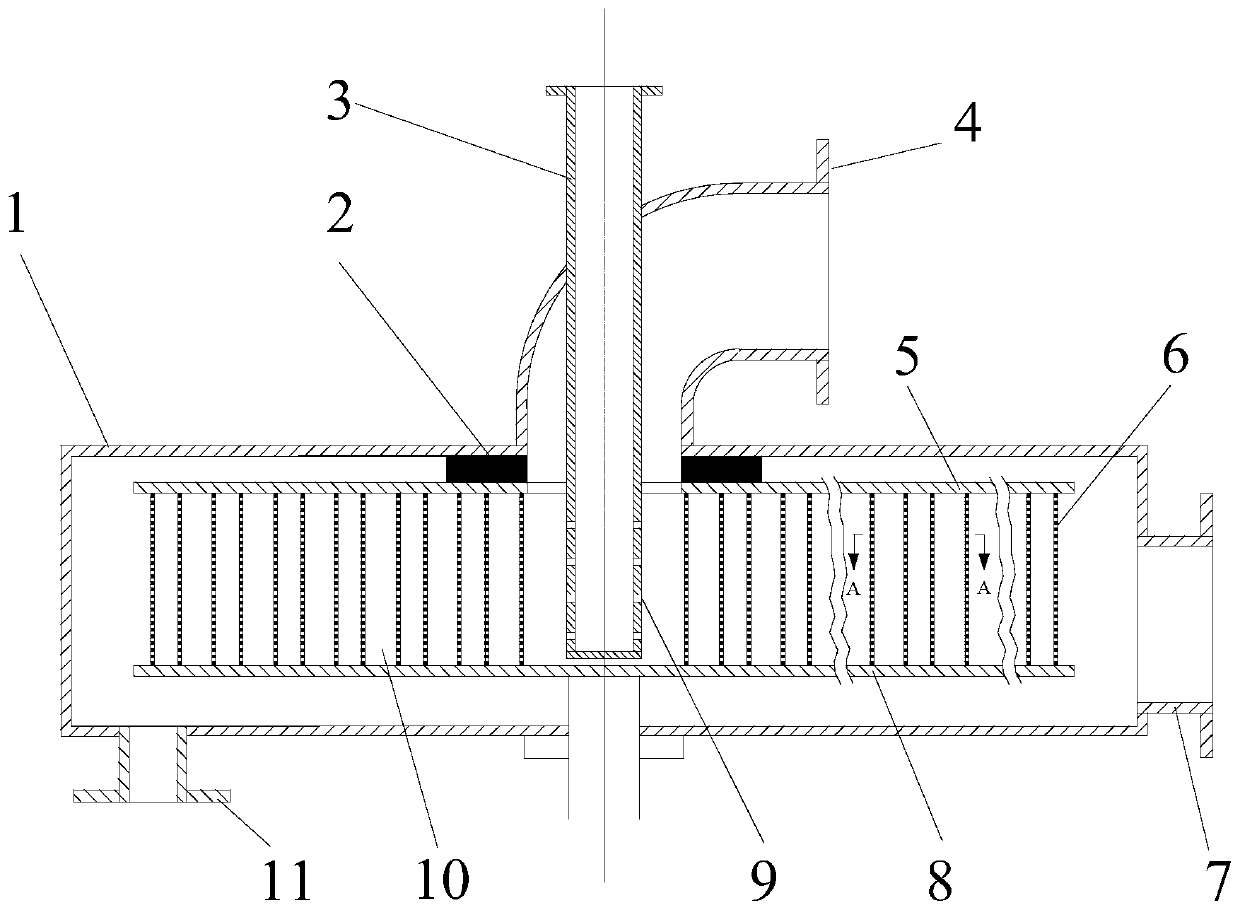

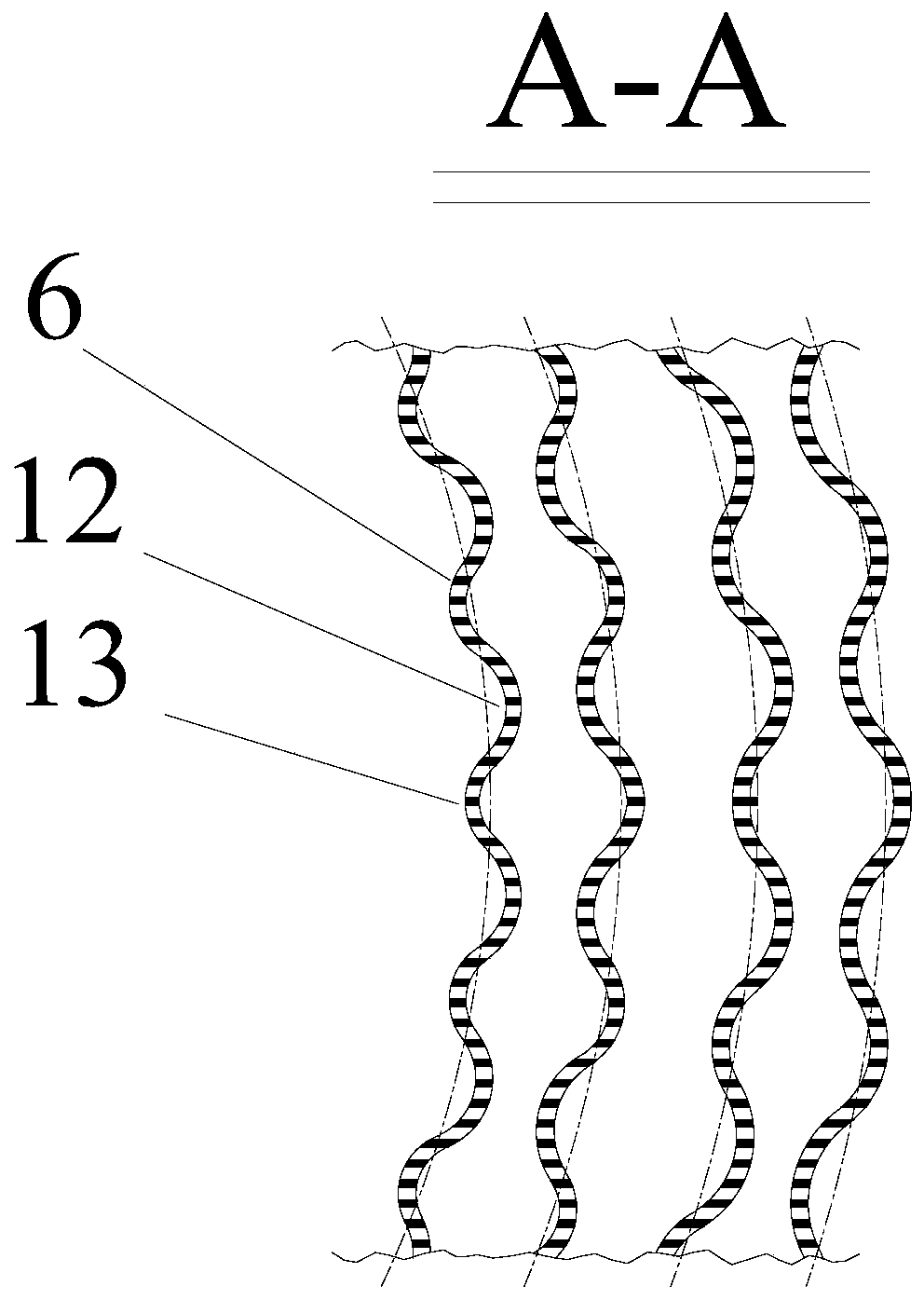

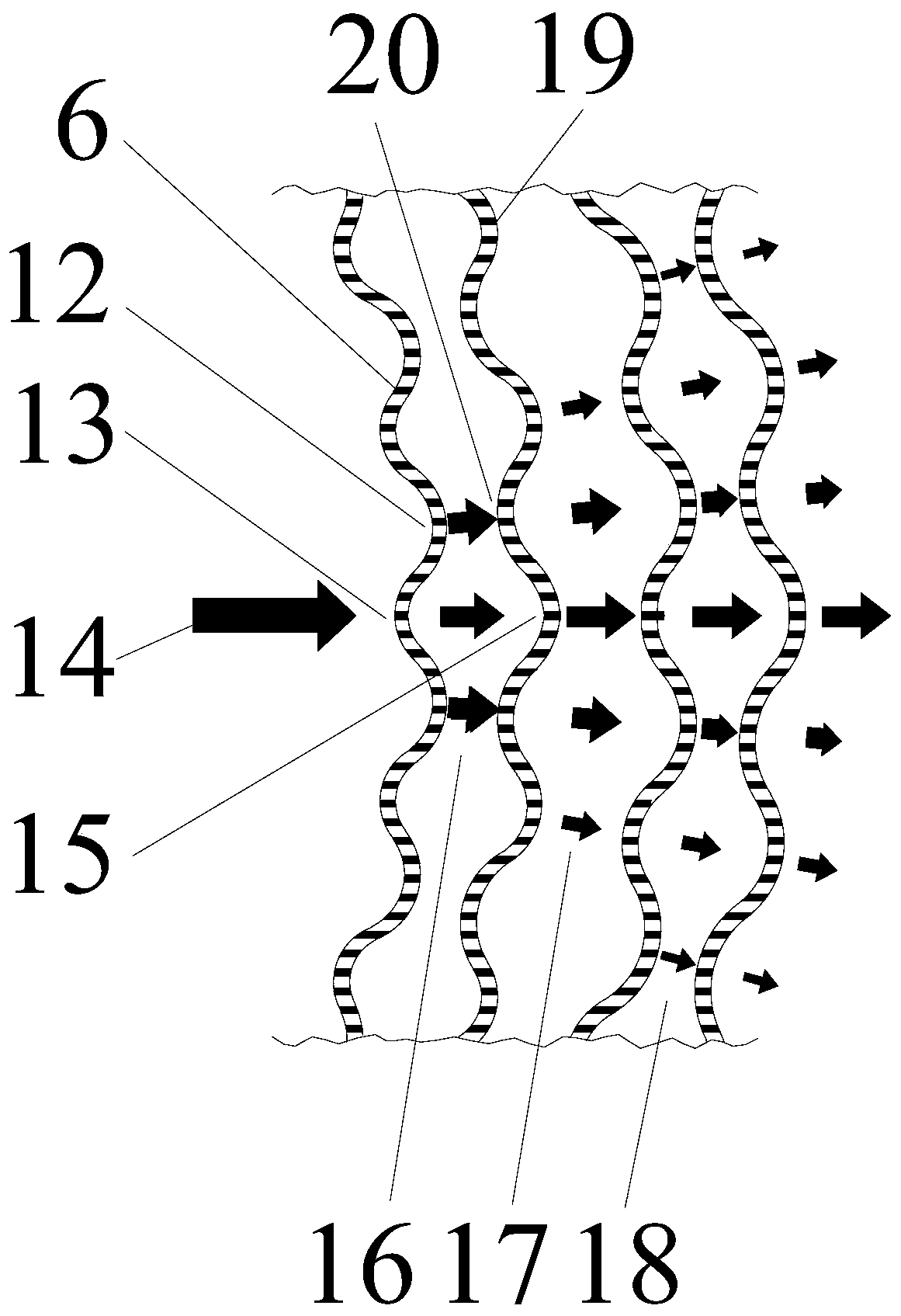

[0015] Embodiment 1: as attached figure 1 As shown, this concentric corrugated ring rotary bed mainly includes a cavity 1, a rotor 10 is arranged in the cavity 1, a dynamic seal 2 is arranged between the rotor 10 and the cavity 1, and a gas seal is arranged on the side of the cavity 1. The inlet pipe 7 is provided with a liquid outlet pipe 11 on the bottom plate of the cavity 1; the rotating shaft 21 of the rotor 11 penetrates from the bottom plate of the cavity 1, and the liquid inlet pipe 3 penetrates the cavity 1 and the rotor from the upper part of the cavity 1 In the central chamber 22 of 10, the liquid inlet pipe 3 with the upper opening and the bottom closed is installed coaxially with the rotating shaft 21, and several liquid outlet holes 9 are also opened on the pipe wall of the liquid inlet pipe 3; the gas outlet pipe 4 is arranged on the cavity The upper panel of the body 1 and communicates with the central chamber 22 of the rotor 10; the rotor 10 is composed of an ...

Embodiment 2

[0019] Embodiment 2: When the present invention is used for rectification, the gas from the reboiler enters the inner cavity of the cavity 1 from the gas inlet pipe 7, passes through the rotor 10 in the radial direction, contacts with the liquid in countercurrent, and finally passes through the gas outlet The pipe 4 enters the condenser to condense to obtain the rectification product; part of the condensate enters from the liquid inlet pipe 3 as reflux liquid, enters the interior of the rotor 10 through the liquid outlet hole 9 on the liquid inlet pipe, and is accelerated and thrown out under the action of centrifugal force. The liquid is crushed into fine liquid foam and liquid silk, and contacts with the gas countercurrently for mass transfer and heat transfer. The liquid enters the reboiler through the liquid outlet pipe 11 to be heated, and the rectified product is discharged from the reboiler.

[0020] With ethanol-water as the substance system, under the rotating speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com