Gear milling machine tool

A technology for milling gears and machine tools, which is applied in the direction of gear teeth manufacturing devices, gear cutting machines, belts/chains/gears, etc. It can solve the problems of increasing difficulty, hob axial runout, and not wide, so that it is not easy to move relative to each other and avoid left and right Offset, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

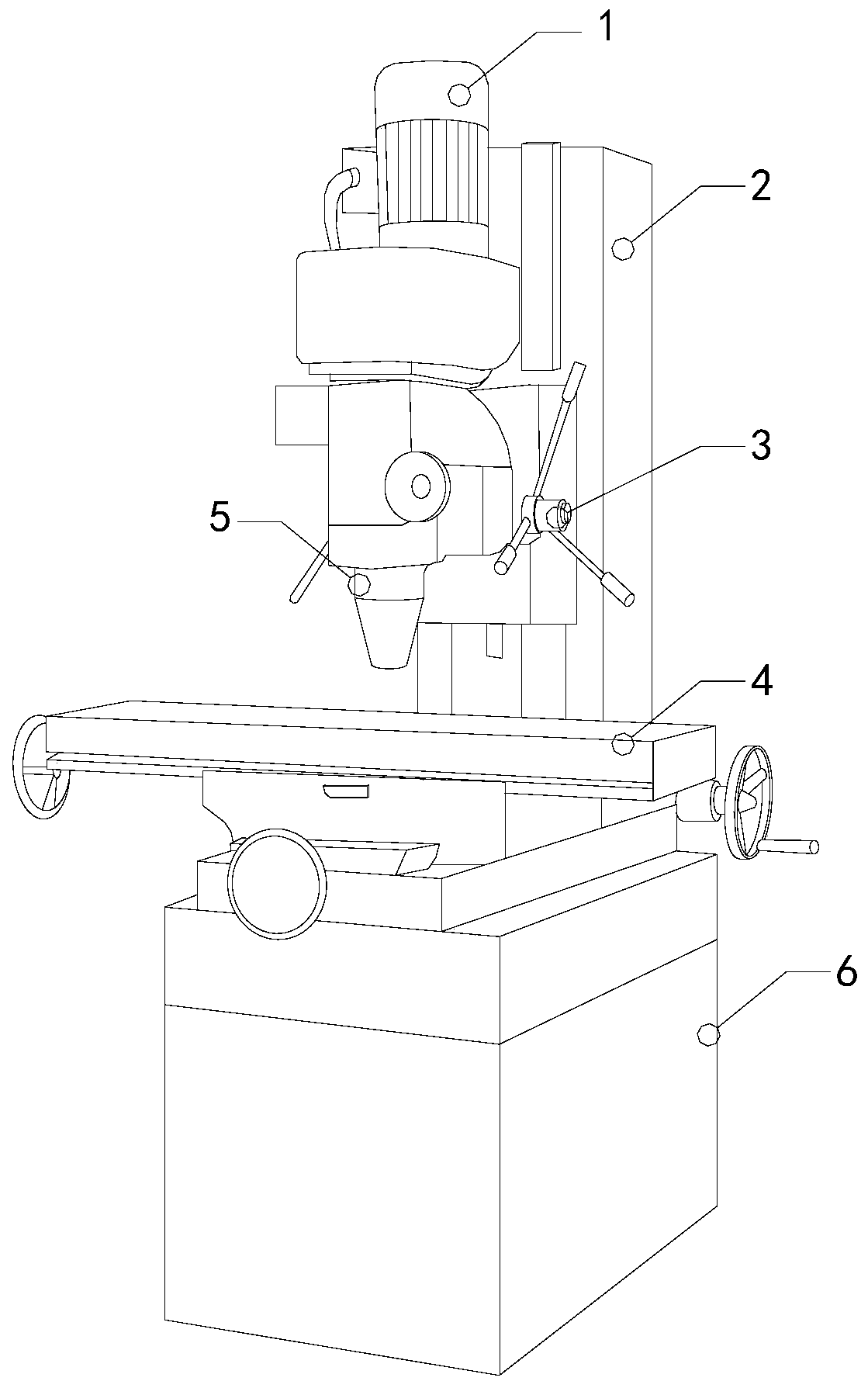

[0028] see Figure 1-Figure 6 , the present invention provides a gear milling machine tool, the structure of which includes a motor 1, an electric control box 2, a control hand 3, a mobile lathe 4, a cutter head structure 5, and a bottom box 6, and a mobile Lathe 4, an electric control box 2 is vertically welded on the bottom box 6 next to the mobile lathe 4, a cutter head structure 5 is arranged directly above the mobile lathe 4, and the cutter head structure 5 is mechanically connected to the output shaft of the motor 1, The motor 1 is close to the top of the electric control box 2 and is electrically connected with it.

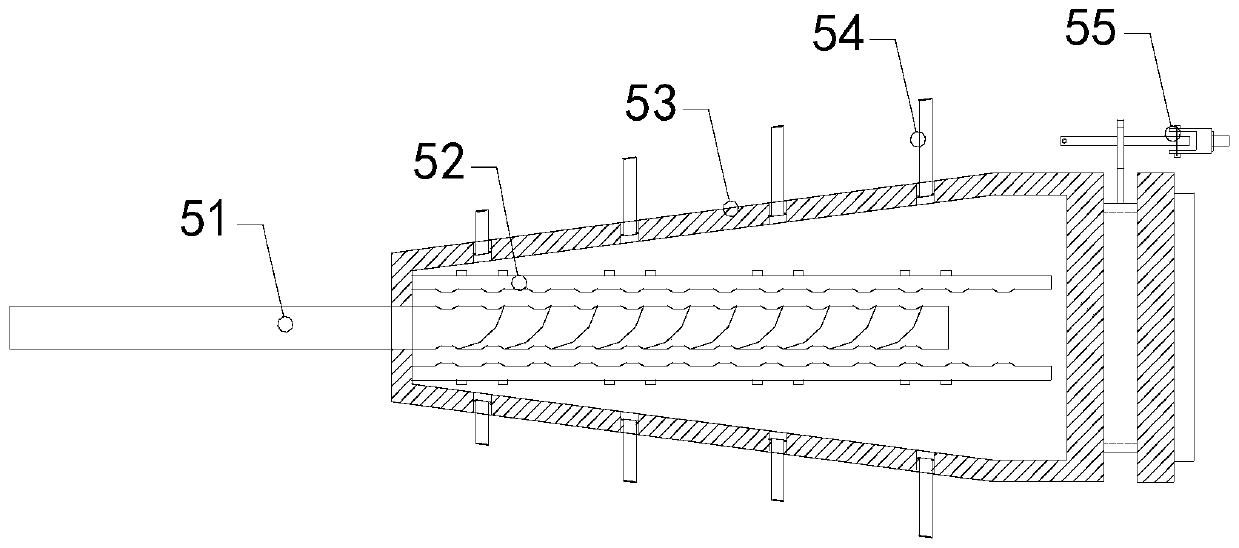

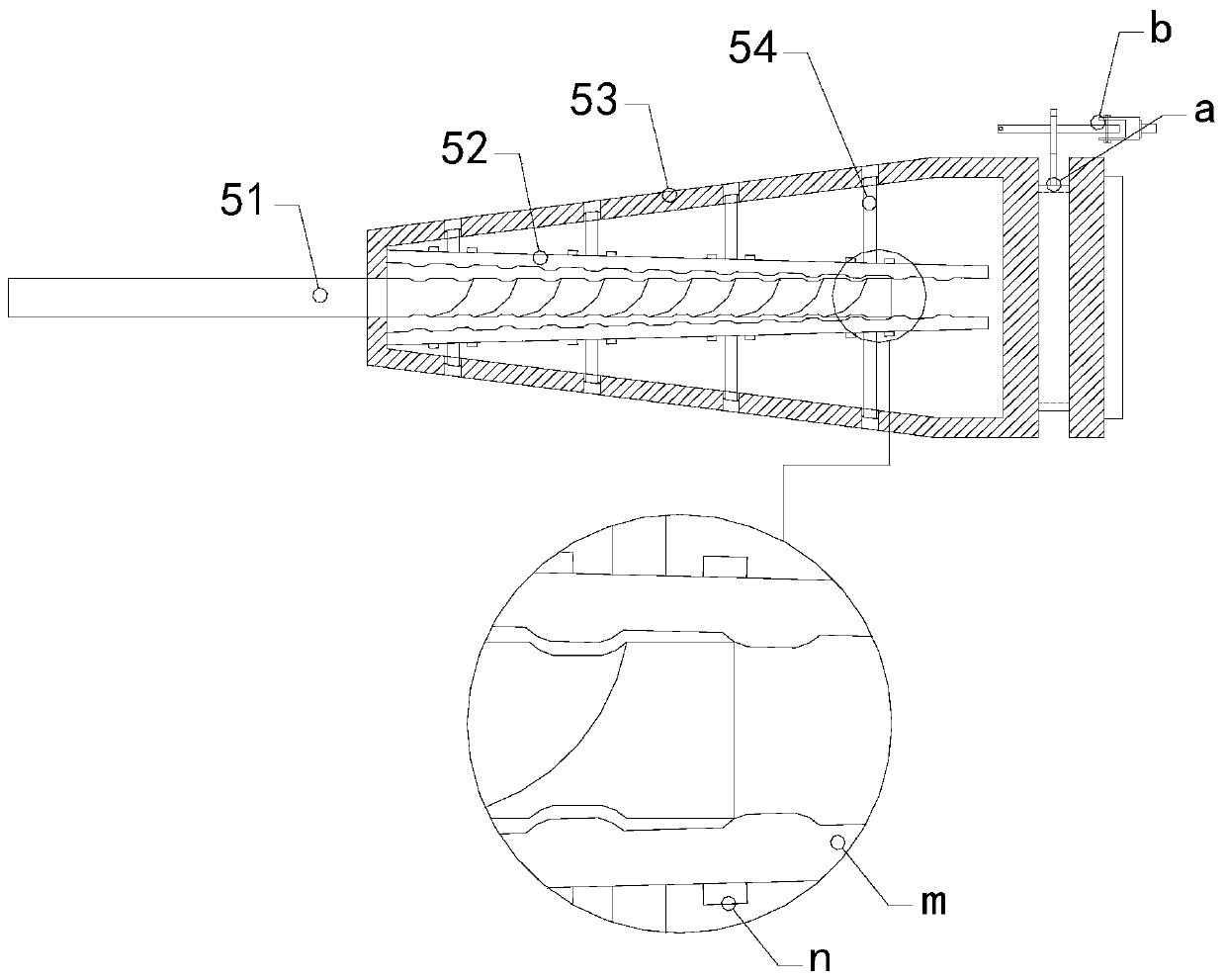

[0029] Described cutter head structure 5 comprises cutter head 51, clamp bar 52, shell 53, locking bar 54 and forms, and described shell 53 is the hollow taper structure, not only can clamp cutter head 51, also allows clamp bar 52 to possess sufficient space, the end of the housing 53 with a relatively small diameter clamps the cutter head 51, the cutter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com