Mold dragging and putting rack convenient to move

A mold and frame technology, applied in the field of mold storage devices, can solve the problems of small number of stored molds, inconvenient moving and loading and unloading, and unreasonable use of space, so as to achieve the effect of improving the fixing firmness and facilitating loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

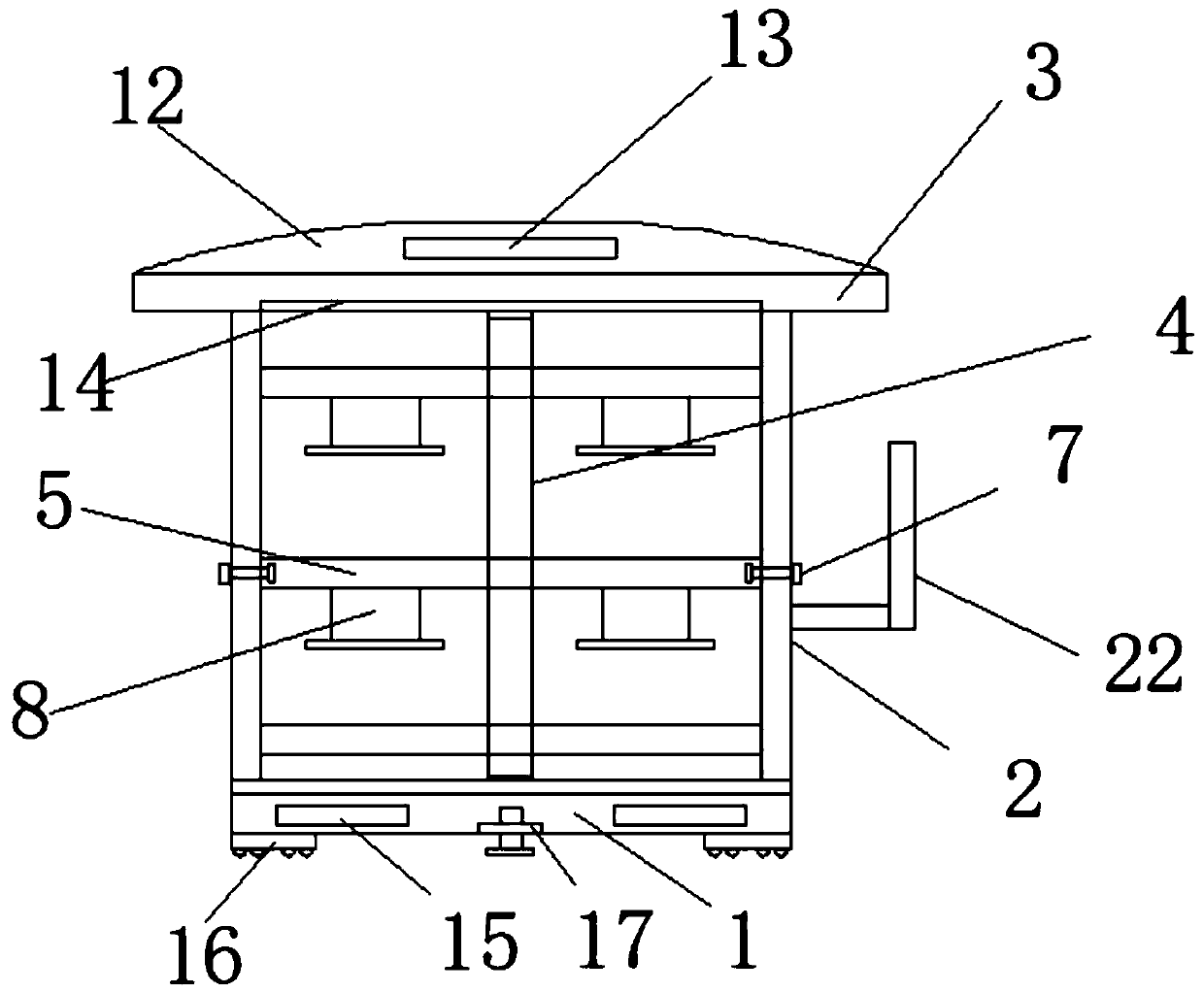

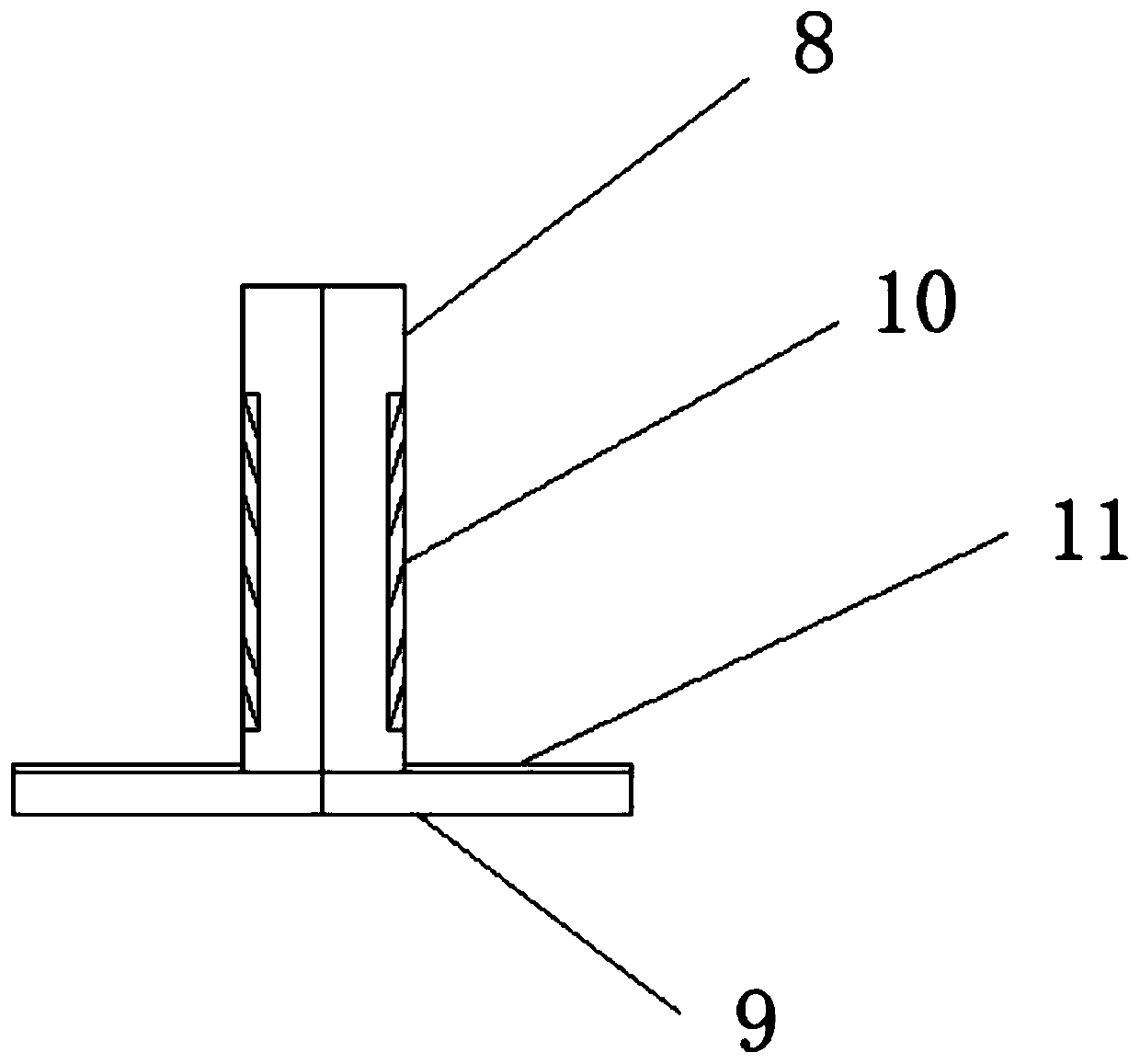

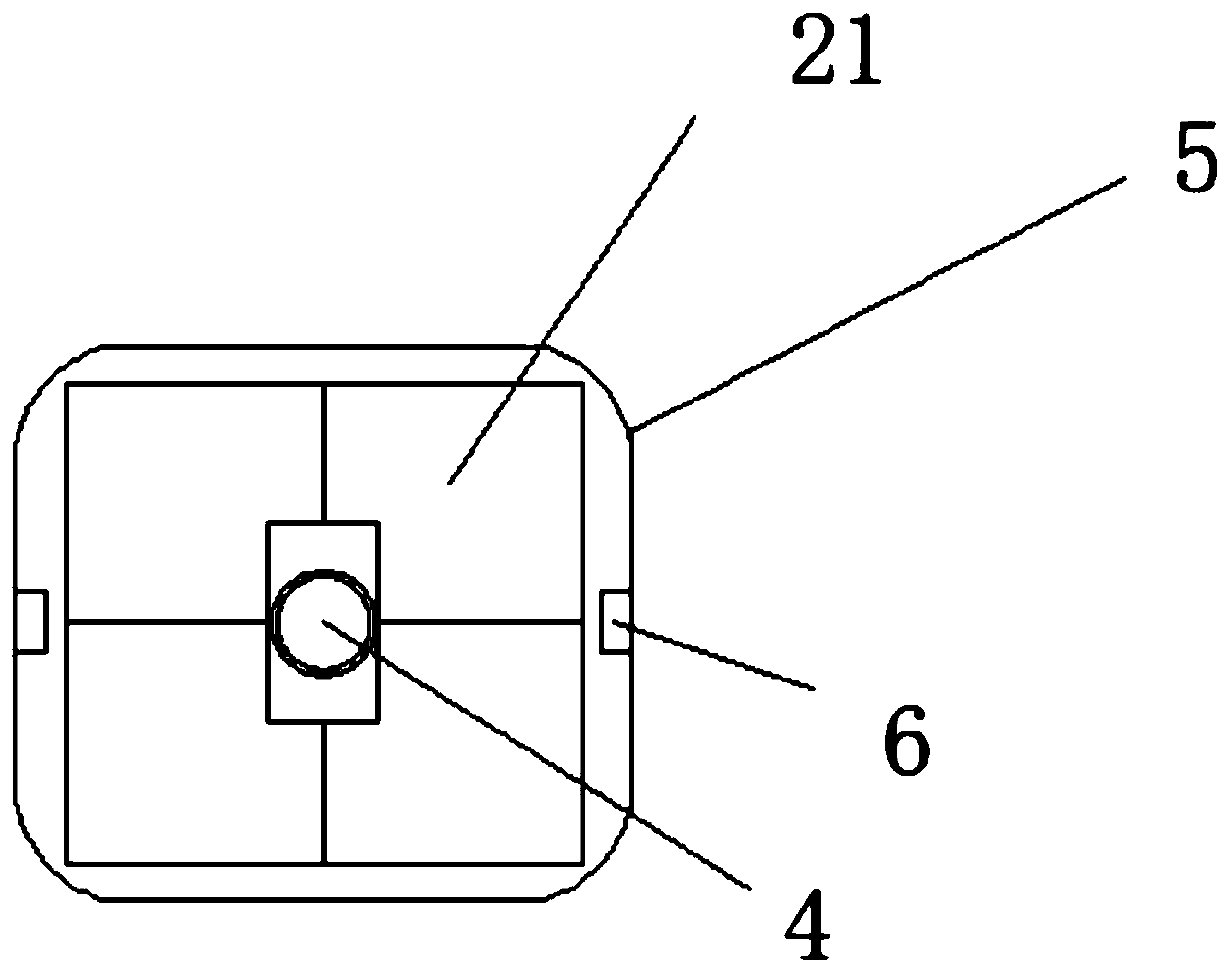

[0024] like Figure 1-4 As shown, a mold drag-and-drop rack that is easy to move includes a base 1, a frame 2 is welded on the top of the base 1, and a support column 4 is installed on the inner bottom of the frame 2, and the surface of the support column 4 is buckled. A supporting plate 5 is installed, the top surface of the supporting plate 5 is provided with a mold placement groove 21, the surface of both sides of the supporting plate 5 is provided with limiting holes 6, the surfaces of both sides of the frame 2 are rotatably mounted with fastening bolts 7, One end of the fastening bolt 7 is rotatably installed in the limit hole 6, the bottom surface of the supporting plate 5 is welded with an extension backing plate 8, the bottom end of the extension backing plate 8 is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com