Direct-connection cantilever-type self-reel-changing reeling and unreeling device

A rewinding and unwinding, cantilever technology, applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems of stop impact, complex structure design, difficult to hold tension, etc., to improve stability and accuracy , The effect of simplifying the support method and improving the running rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

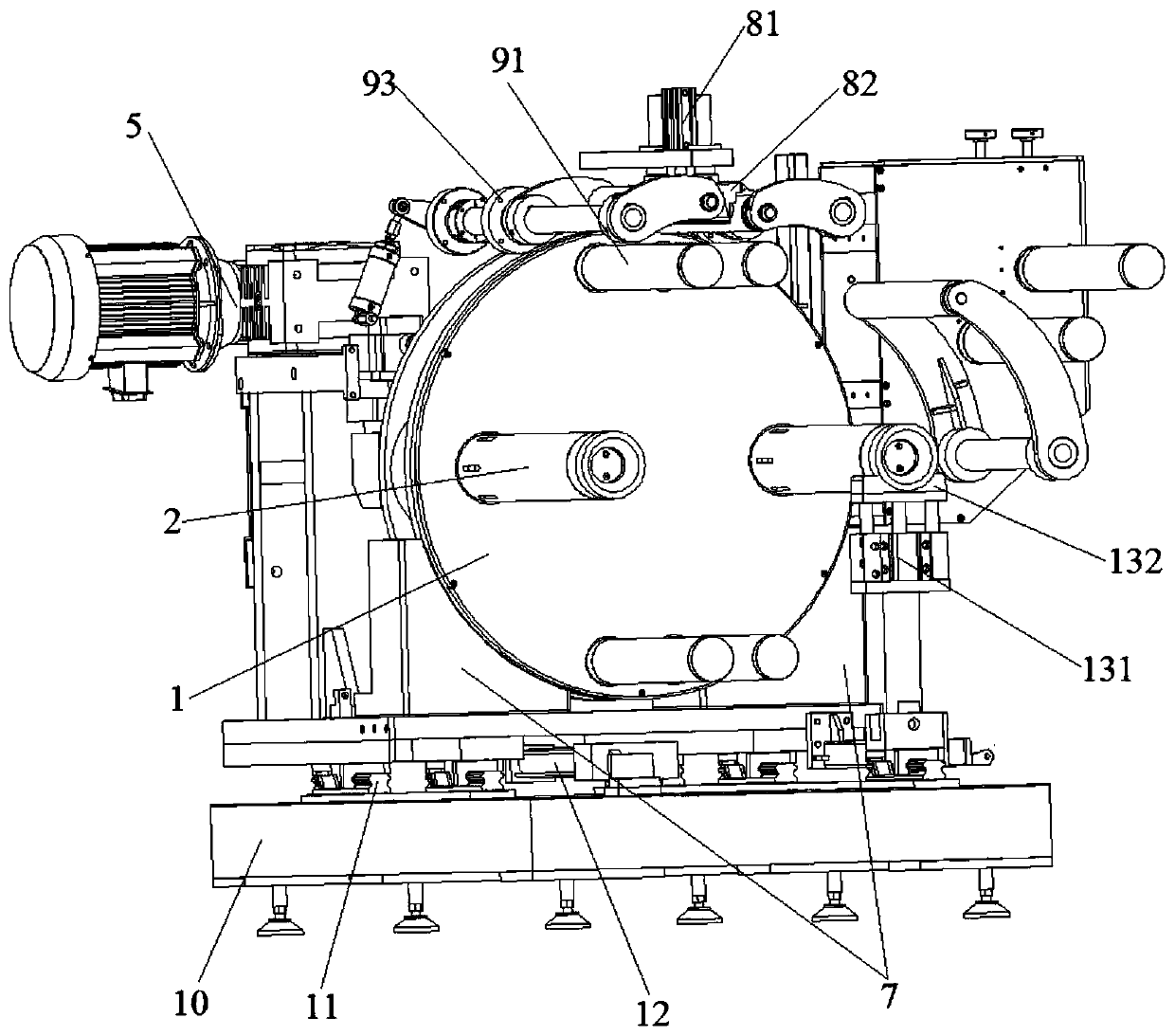

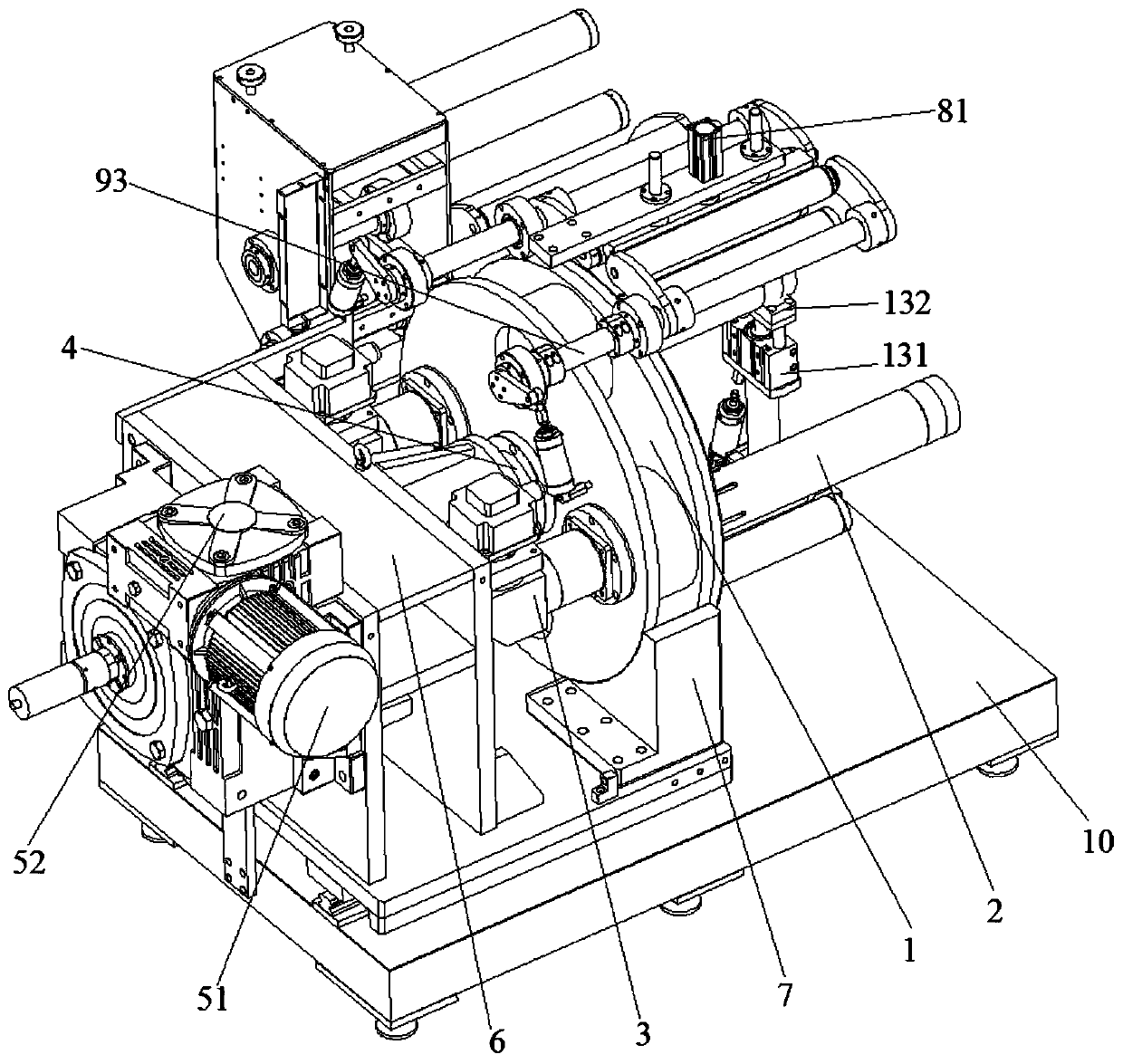

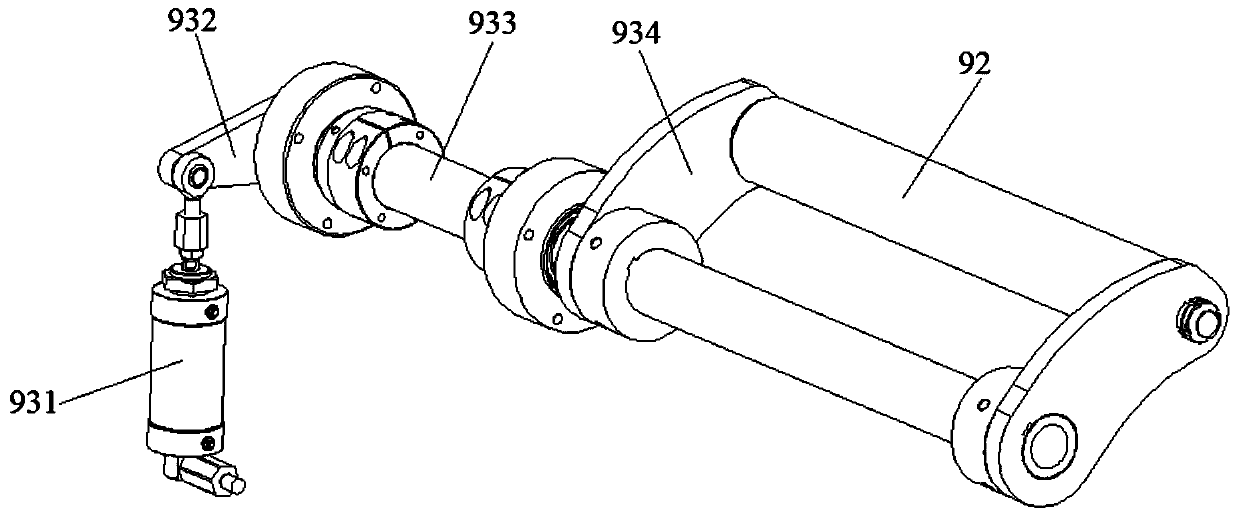

[0017] A direct-coupled cantilever type self-changing rewinding and unwinding device proposed in this embodiment, refer to figure 1 and figure 2 , including a turntable 1, the first side of the turntable 1 is symmetrically provided with two unwinding main shafts 2 for installing materials, and the second side of the turntable 1 is provided with servos connected coaxially with the two unwinding main shafts 2 respectively. Motor 3; the center of the second side of the turntable 1 is coaxially connected to a rotating main shaft 4, and the other end of the rotating main shaft 4 is connected to the driving end of a rotating drive mechanism 5; between the turntable 1 and the rotating drive mechanism 5 A bearing seat 6 is also added, the rotating main shaft 4 is passed through the bearing seat 6, two tapered roller bearings 7 for supporting the turntable 1 are symmetrically installed on the bearing seat 6, and the two tapered roller bearings The bearing 7 is in sliding contact with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com