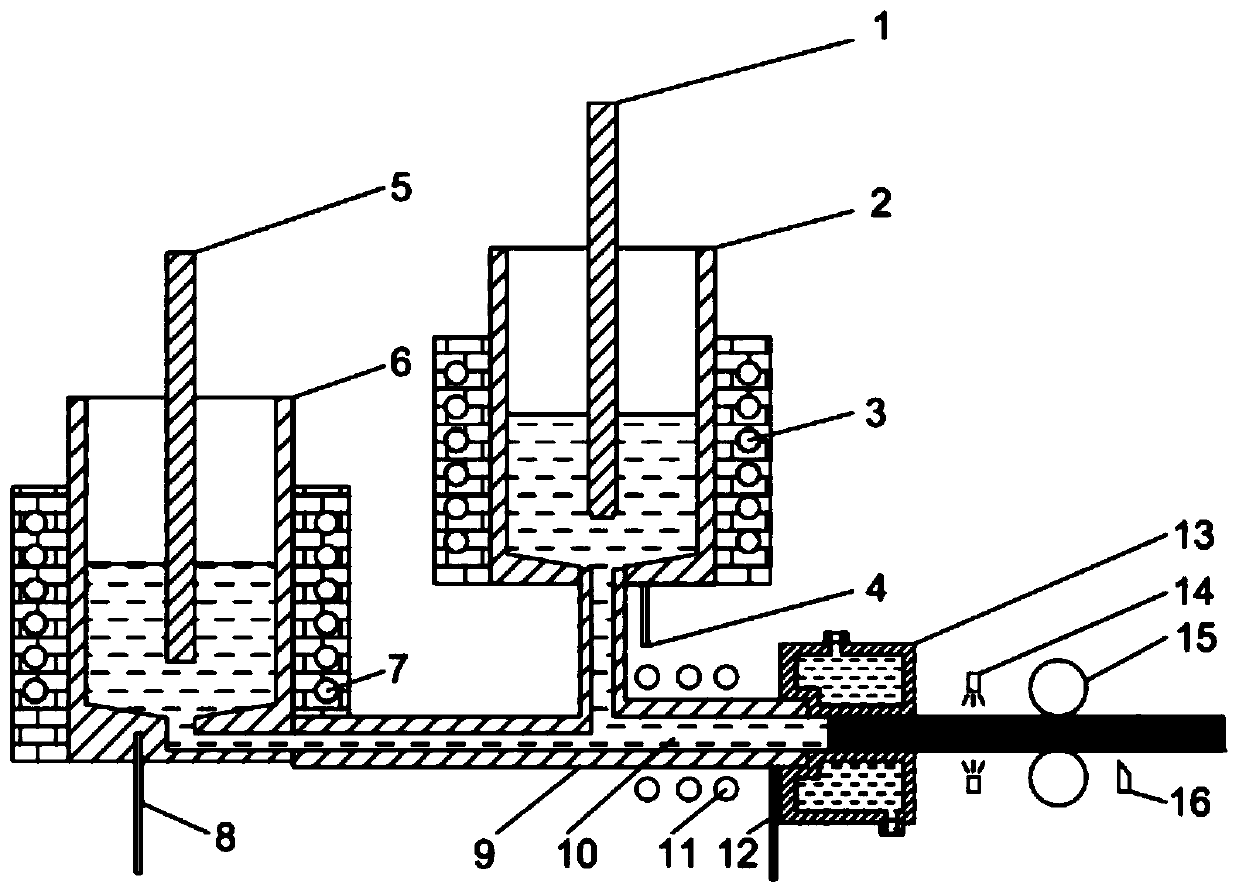

Immiscible alloy preparation method and continuous casting device

An immiscible alloy and continuous casting technology, which is applied in the field of immiscible alloy material preparation, can solve the problems of immiscible alloy composition and uneven structure, so as to facilitate automatic continuous production, suppress fine structure, debugging and production The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: the preparation of Cu-10wt.%Fe composite material

[0059] Put the electrolytic pure copper into the melting chamber of the metal melting furnace A1, heat, melt and keep warm with the induction heater A3, the melting temperature measured by the first temperature measuring element 4 is 1180°C, and the holding temperature is 1180°C.

[0060] Put pure iron and electrolytic copper with a mass ratio of Fe:Cu=1:4 into the melting chamber of the metal melting furnace B6, heat, melt and keep warm through the induction heater B7, and measure the melting temperature through the second temperature measuring element 8 It is 1450 ℃, and the holding temperature is 1450 ℃.

[0061] After the pure Cu liquid and the Fe-Cu alloy liquid reach the target temperature, start the first stopper mechanism 1 and the second stopper mechanism 5, respectively allow the pure Cu liquid and the Fe-Cu alloy liquid to enter the mixing chamber 10 through the guide tube 9 Mixing in the mixi...

Embodiment 2

[0062] Embodiment 2: the preparation of Cu-20wt.%Co composite material

[0063] Put the electrolytic pure copper into the melting chamber of the metal melting furnace A1, heat, melt and keep warm with the induction heater A3, the melting temperature measured by the first temperature measuring element 4 is 1180°C, and the holding temperature is 1180°C.

[0064] Put pure cobalt and electrolytic copper with a mass ratio of Co:Cu=2:3 into the melting chamber of the metal melting furnace B6, heat, melt and keep warm through the induction heater B7, and measure the melting temperature through the second temperature measuring element 4 It is 1600 ℃, and the holding temperature is 1600 ℃.

[0065] After the pure Cu liquid and the Co-Cu alloy liquid reach the target temperature, start the first stopper mechanism 1 and the second stopper mechanism 5, respectively allow the pure Cu liquid and the Co-Cu alloy liquid to enter the mixing chamber 10 through the guide tube 9 Mixing is carrie...

Embodiment 3

[0067] Embodiment 3: the preparation of Cu-10wt.%Ag composite material

[0068] Put the electrolytic pure copper into the melting chamber of the metal melting furnace A1, heat, melt and keep warm with the induction heater A3, the melting temperature measured by the first temperature measuring element 4 is 1180°C, and the holding temperature is 1180°C.

[0069] Put pure silver and electrolytic copper with a mass ratio of Ag:Cu=1:4 into the crucible B6 of the metal melting furnace B, heat, melt and keep warm through the induction heater B7, and measure the melting through the second temperature measuring element 8 The temperature is 1200°C, and the holding temperature is 1200°C.

[0070] After the pure Cu liquid and the Ag-Cu alloy liquid reach the target temperature, start the first stopper mechanism 1 and the second stopper mechanism 5, and allow the pure Cu liquid and the Ag-Cu alloy liquid to enter the mixing chamber 10 through the guide tube 9 respectively Mixing in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com