Sand filling, rainwater recharging and water storing method for waste motor-pumped well

A sand and rainwater technology, applied in water supply devices, drinking water devices, water resources protection, etc., can solve the problem of slow water seepage rate decline, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

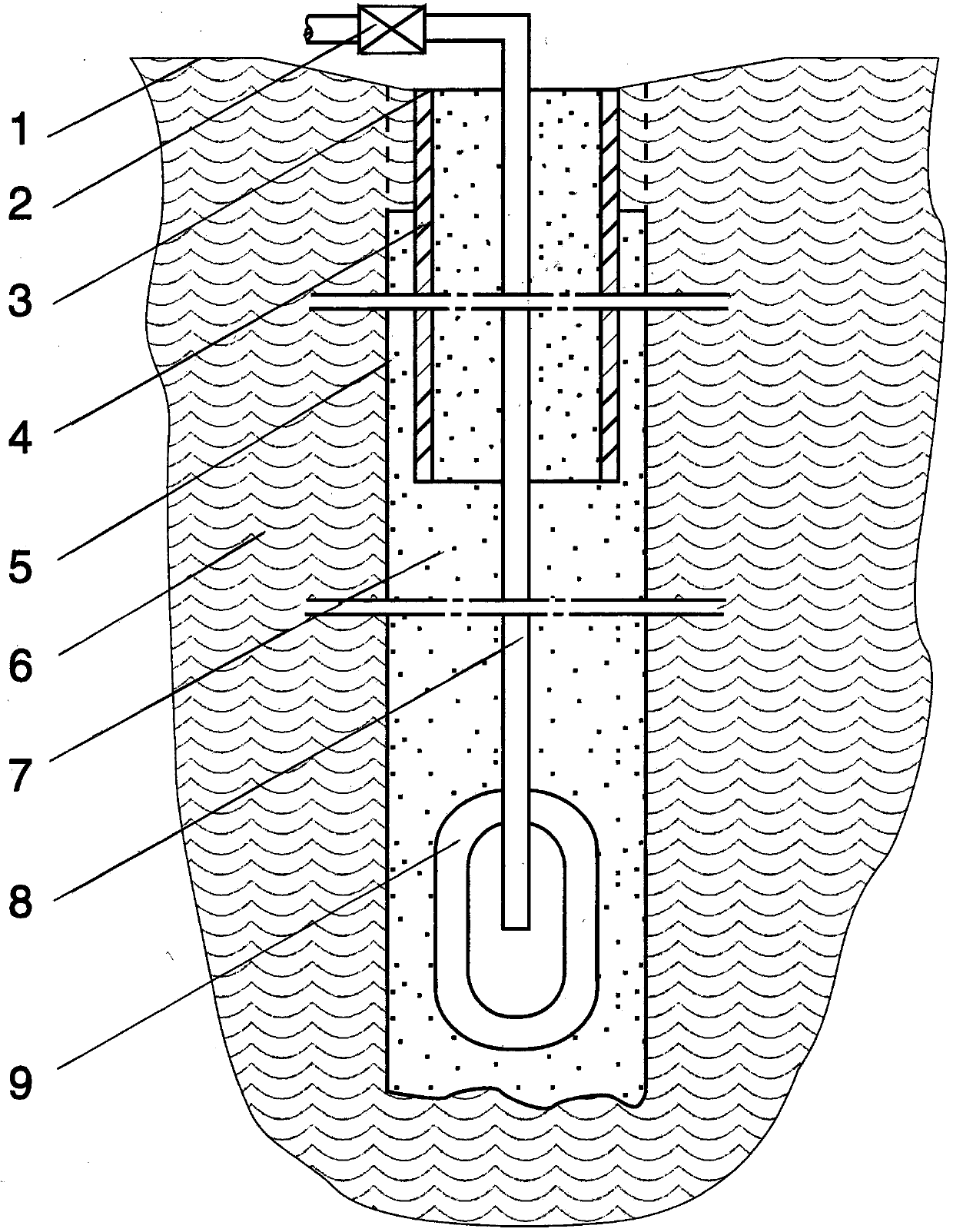

[0021] Clean up the debris and mud at the bottom of the dry well (5), fill the bottom of the well with sand (7) 0.5 meters deep, put the cylindrical filter column (9) connected to the water pipe (8) into the well, and the water pipe ( 8) Receive on the ground (1), then or dry well (5) is filled with sand (7) again, just become the well that fills sand, and well head (3) suitably arranges, builds a well head (3) with brick and cement Well, if the wellhead (3) is not built, the wellhead will be enlarged, and more sand (7) will be put. The wellhead (3) will be lower than the ground (1), and a small ditch can be set on the ground (1), so that the rainwater is all towards the wellhead (3 )flow. On rainy days, the rainwater flows into the sand well naturally, and the rainwater infiltrates into the bottom of the well along the gaps in the sand (7), without manual management. After a long time, the sand (7) at the wellhead (3) will filter the soil. Replace the sand with mud, or shove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com