Steel pipe concrete column H-shaped steel beam fabricated rigid joint strong beam strong column structure and construction method

A technology of steel tube concrete column and H-shaped steel, which is applied in the direction of building structure, construction, etc., can solve the problems of small rigidity and non-directionality, and achieve the effect of high bearing capacity, large extension length, and strengthened cooperative work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to better understand the present invention, the invention will be described in further detail below in conjunction with the accompanying drawings and implementation examples, but the implementation of the present invention is not limited thereto, and the scope of protection of the present invention is also designed by those skilled in the art according to the concept of the present invention. Think of the equivalent technical means.

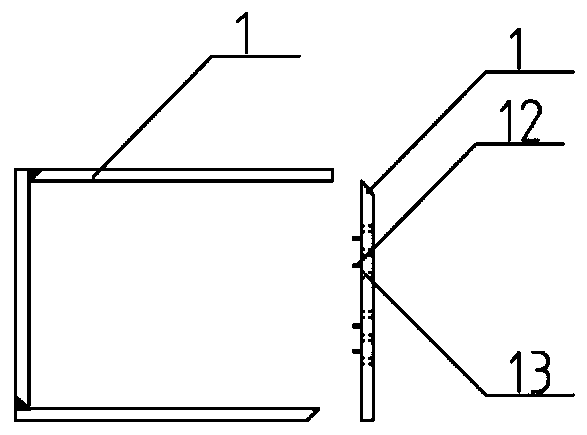

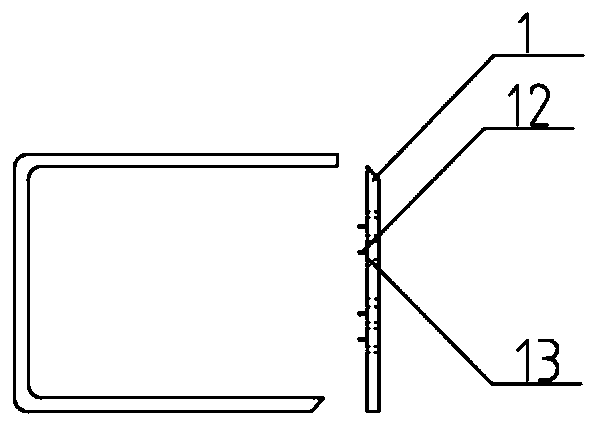

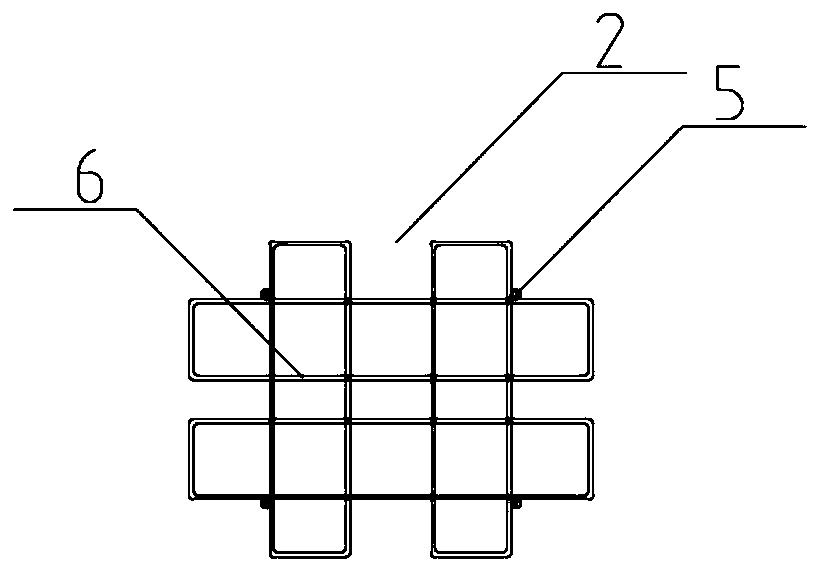

[0073] Figure 1 to Figure 18 As shown, a concrete-filled steel tube column H-shaped steel beam assembled rigid-connected node strong beam-strong column structure includes a steel tube concrete column with tension bars, an assembled rigid strong node and an H-shaped steel beam.

[0074] In order to better understand the present invention, two examples are now proposed: embodiment 1 is that the node member penetrates the steel plate member, and both the upper and lower node members use H-shaped steel supports; embodiment 2 is that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com