Vehicle air conditioner compressor comprehensive performance testing equipment

A comprehensive performance testing and automotive air-conditioning technology, which is applied to mechanical equipment, pump testing, conveyor objects, etc., can solve the problems of multiple equipment, scattered testing items, repetitive waste of mechanisms, etc., achieve high equipment integration, improve testing efficiency, Avoid the effects of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with example and accompanying drawing, the present invention will be further described.

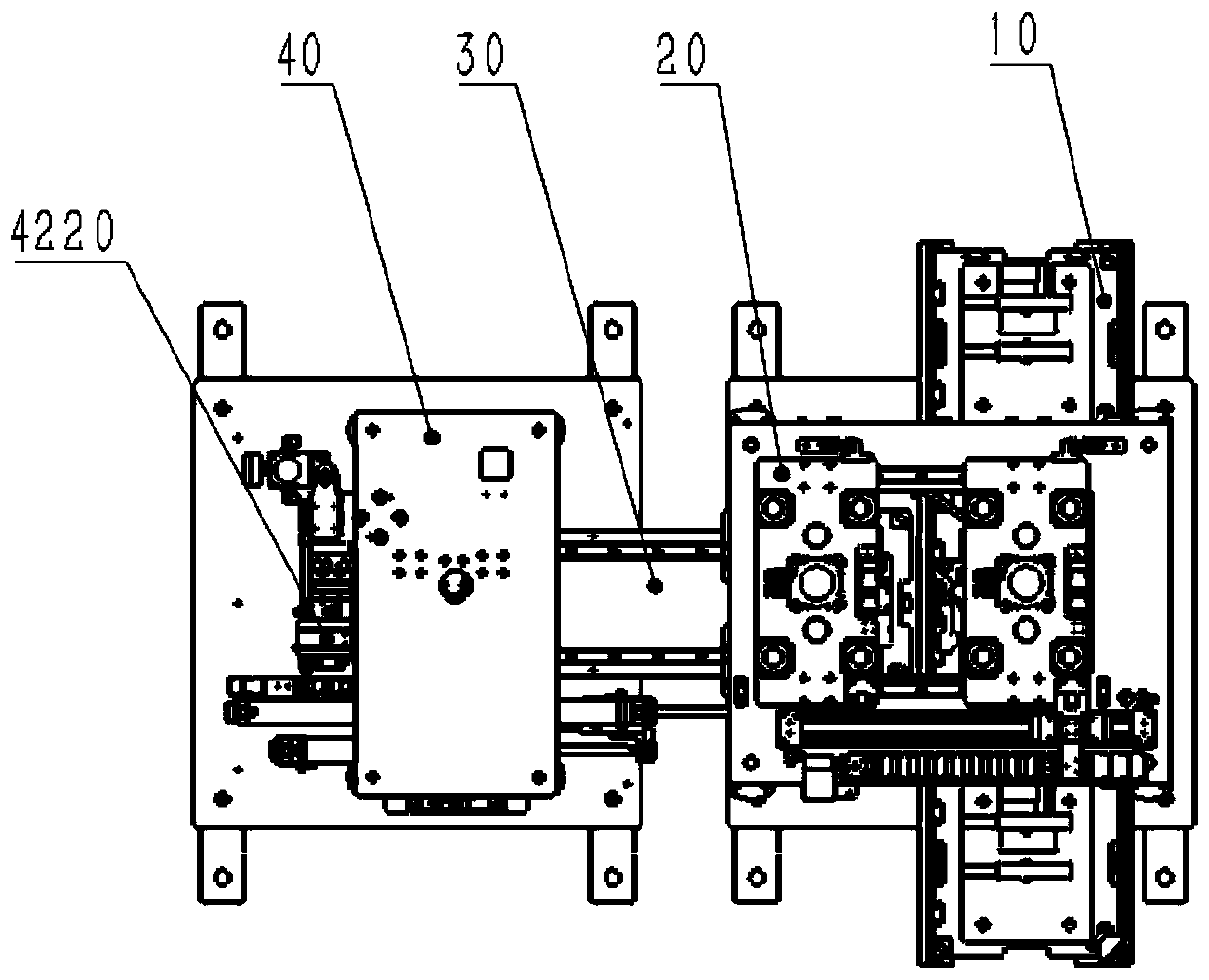

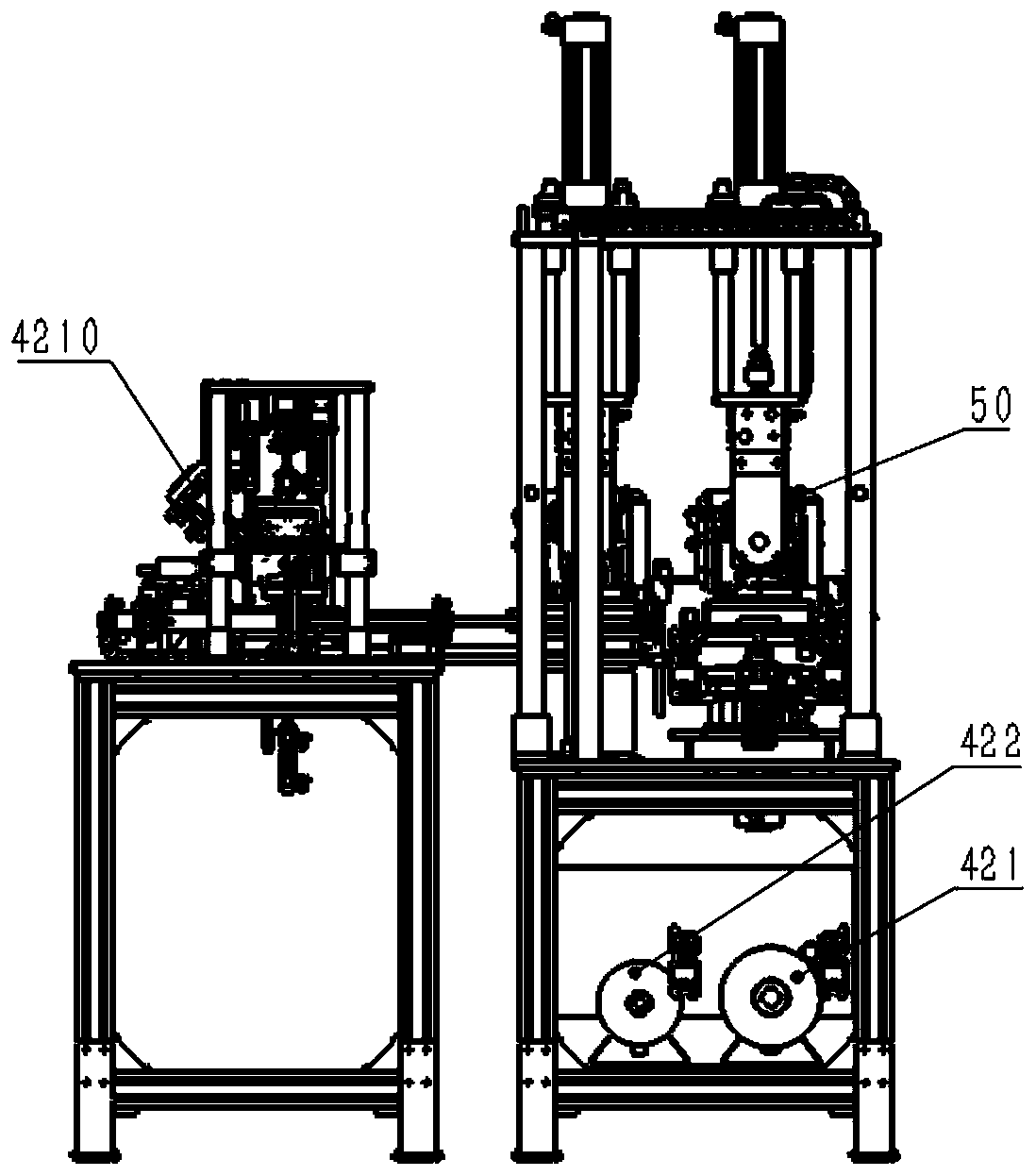

[0034] Such as figure 1 As shown, a comprehensive performance testing device for an automobile air-conditioning compressor includes a feeding and conveying mechanism 10, a feeding and transferring mechanism 20, a test carrying mechanism 30, a function testing mechanism 40, an anechoic room, and a control system.

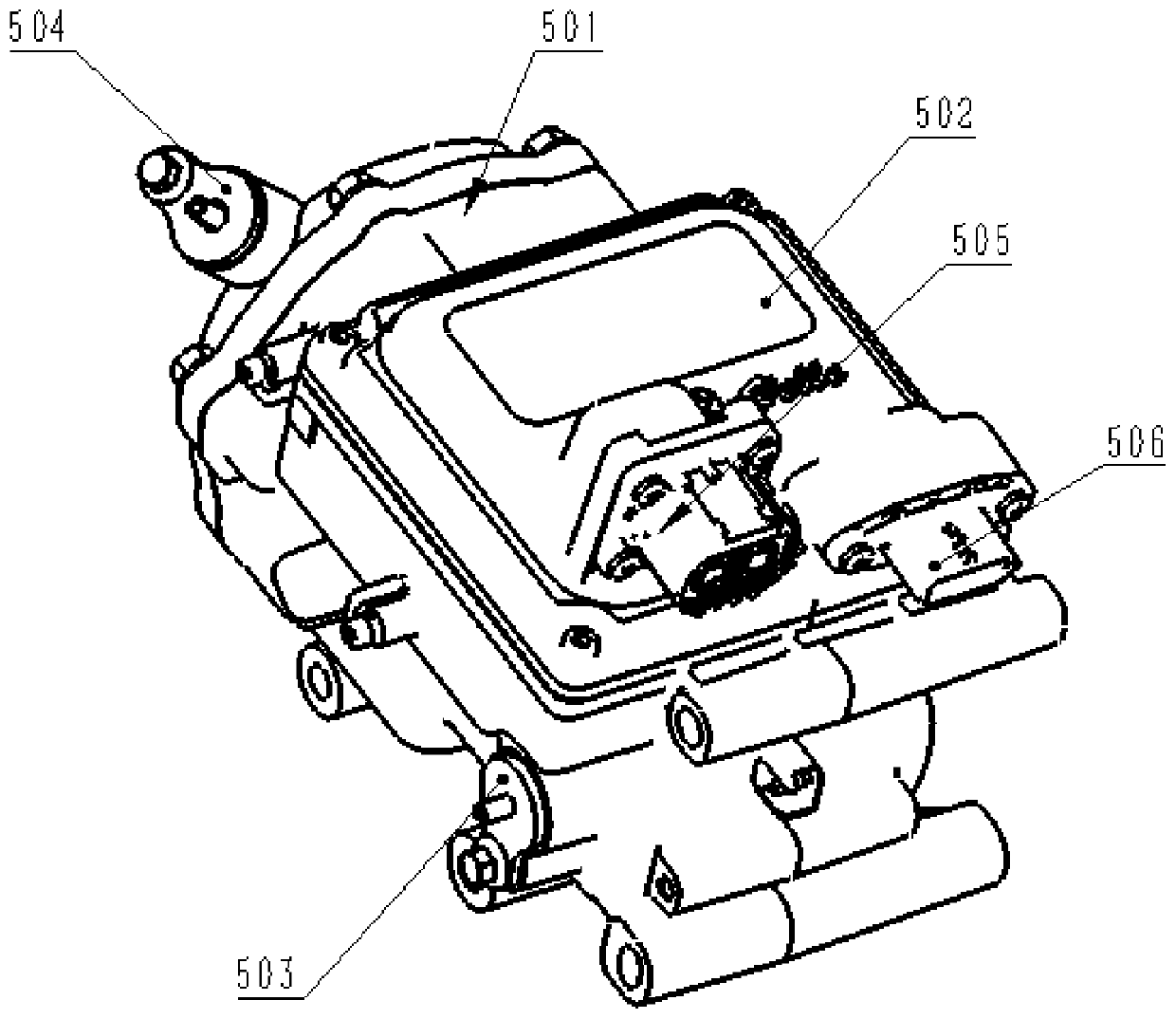

[0035] Such as Figure 2-3 As shown, the rotary electric scroll compressor 50 is externally composed of a housing 501 and a controller 502. There are two vents on the housing 501, which are respectively a suction port 503 and an exhaust port 504. There are two vents on the controller 502. The interfaces are power line interface 505 and signal line interface 506 respectively.

[0036] Such as Figure 4 As shown, the feeding and conveying mechanism 10 includes a blocking mechanism 110 , a jacking and positioning mechanism 120 , several tooling plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com