A vertical LED chip structure and manufacturing method thereof

A technology of LED chips and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., to achieve the effect of increasing the light output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] As mentioned in the background art section, the luminous efficiency of the vertical LED chip structure in the prior art can be further improved.

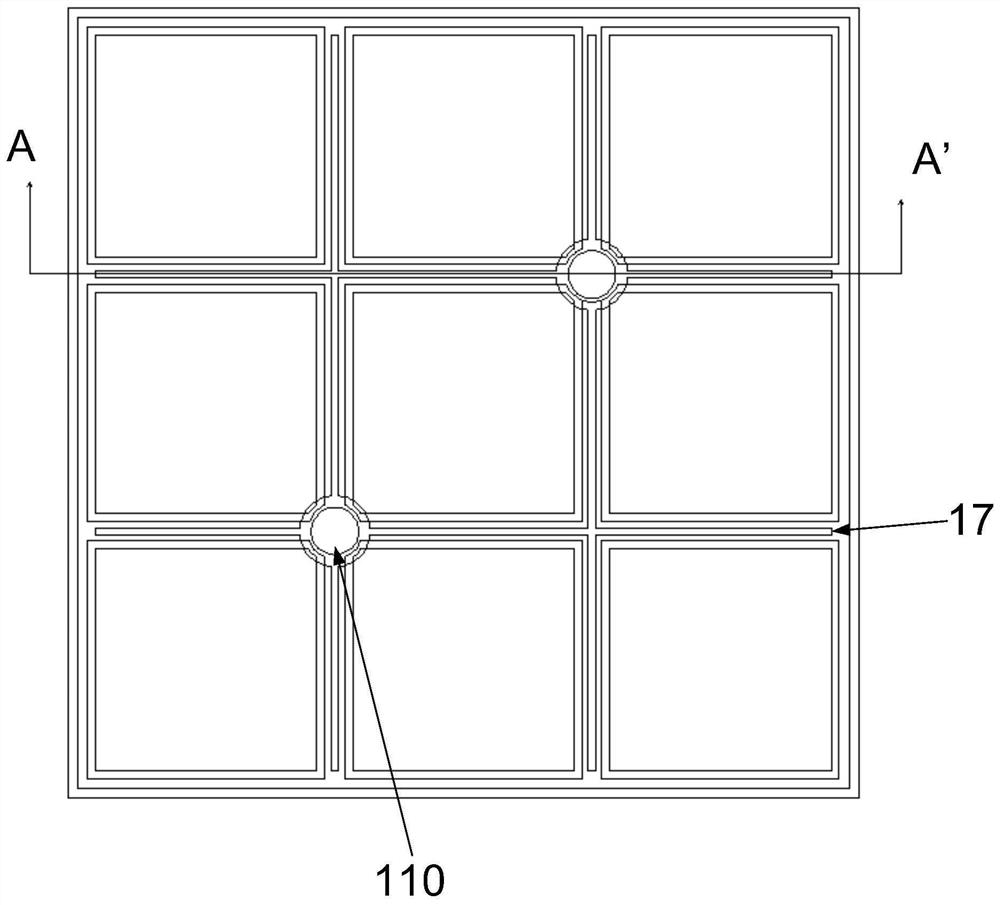

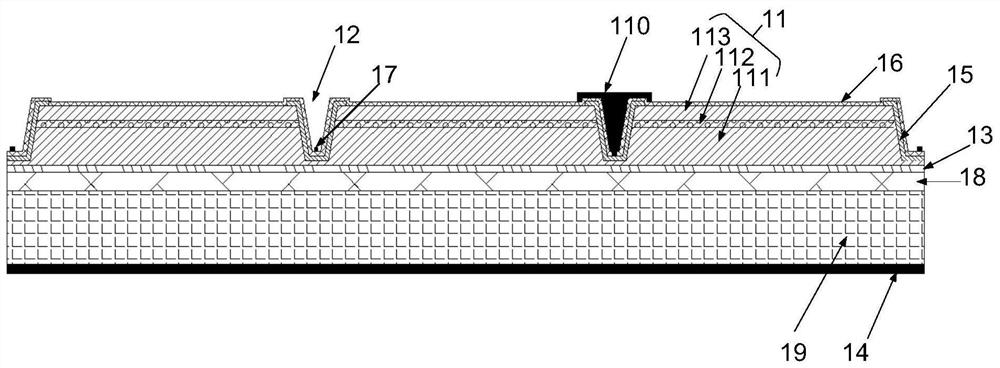

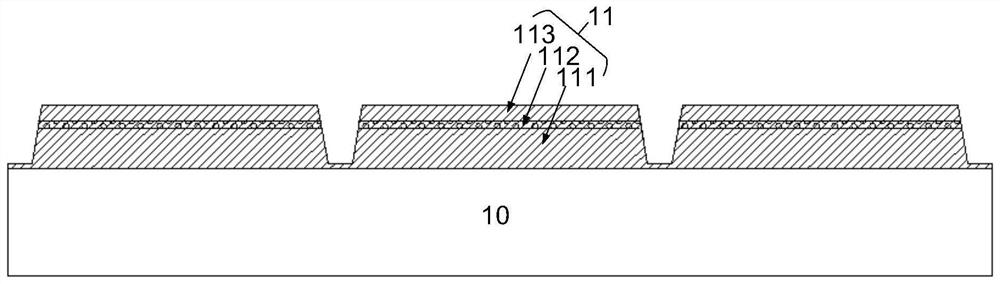

[0075] The inventors found that the reason for the above problems is that in the prior art, for high-power vertical LED chips, the chip area is usually relatively large, and the common ones are 45mil╳45mil, 60mil╳60mil, etc., but the quality of the current epitaxial materials However, defects such as threading dislocations can cause chip failure, and often a small defect can cause the failure of the entire LED chip. Therefore, the larger the area of the LED chip, the lower the overall yield of the chip, but the price of the chip will also be higher. high. Moreover, due to the large refractive index difference between LED epitaxial semiconductor materials and air, the solid angle for photons emitted from multiple quantum wells (MQWs) to escape from the LED surface is very small, and a large proportion of photons are in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com