LED (light-emitting diode) module with cross-over electrode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., and can solve the problem of reduced light output efficiency from the side of light-emitting diodes 12, reduced luminous efficiency of light-emitting diodes 12, and inability to accurately control film thickness, etc. problem, achieve the effect of improving coating uniformity, avoiding expensive equipment, and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

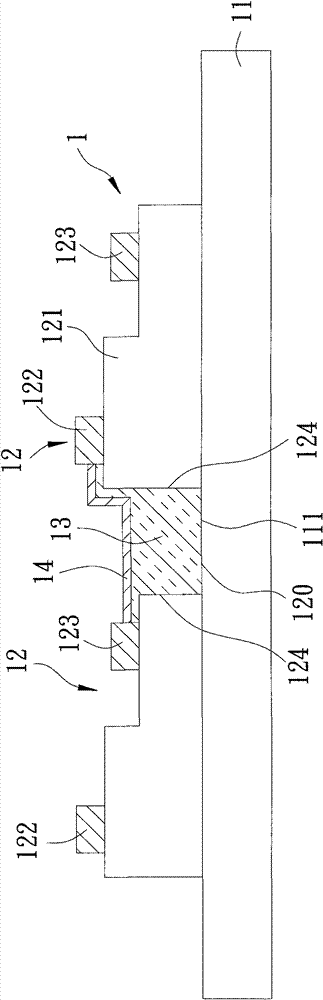

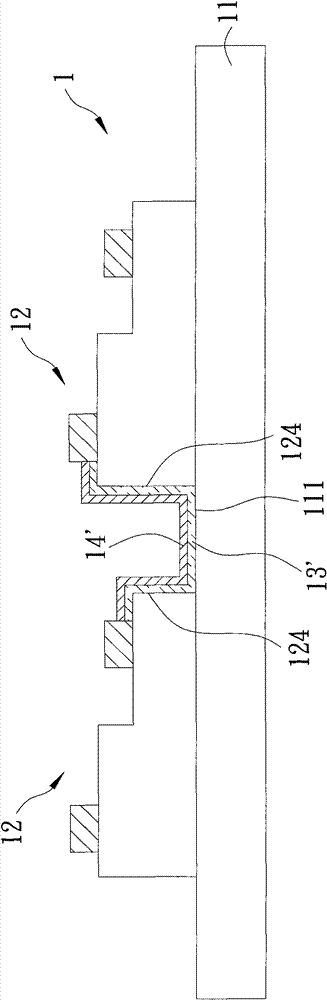

[0027] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

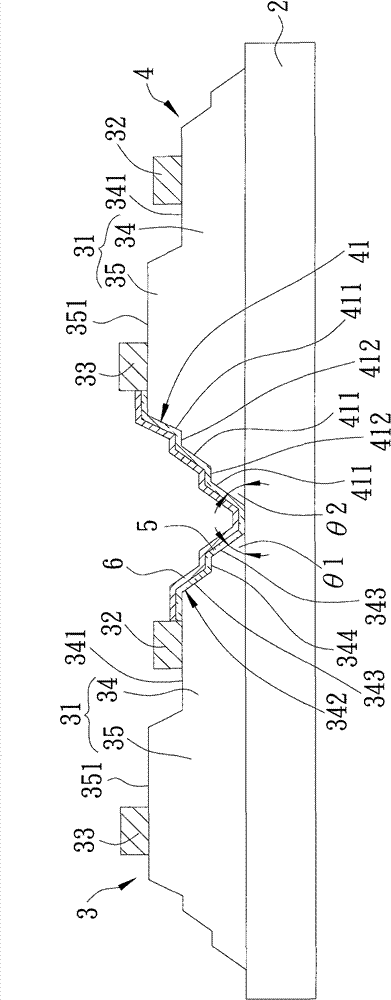

[0028] refer to image 3 , the preferred embodiment of the light-emitting diode module with jumper electrodes in the present invention is suitable for DC-driven LED modules, and is also suitable for AC-driven LED modules, and includes: a substrate 2, located on the left and right intervals A first light emitting diode 3 and a second light emitting diode 4 on the substrate 2 , an insulating layer 5 and a jumper electrode 6 .

[0029] The substrate 2 of the present embodiment is sapphire (Al 2 o 3 ) Substrate 2, but not limited thereto. The first light emitting diode 3 and the second light emitting diode 4 have the same structure, and both include a light emitting body 31, an n-electrode 32 and a p-electrode 33, and the light-emitting body 31 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com