Construction method of prefabricated concrete guide walls

A technology of prefabricated concrete and construction method, applied in the direction of wall, cable installation, cable installation device, etc., can solve the problems of poor waterproof performance, difficult construction, long construction period, etc., to achieve enhanced integrity, simple construction, and save construction period effect on cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

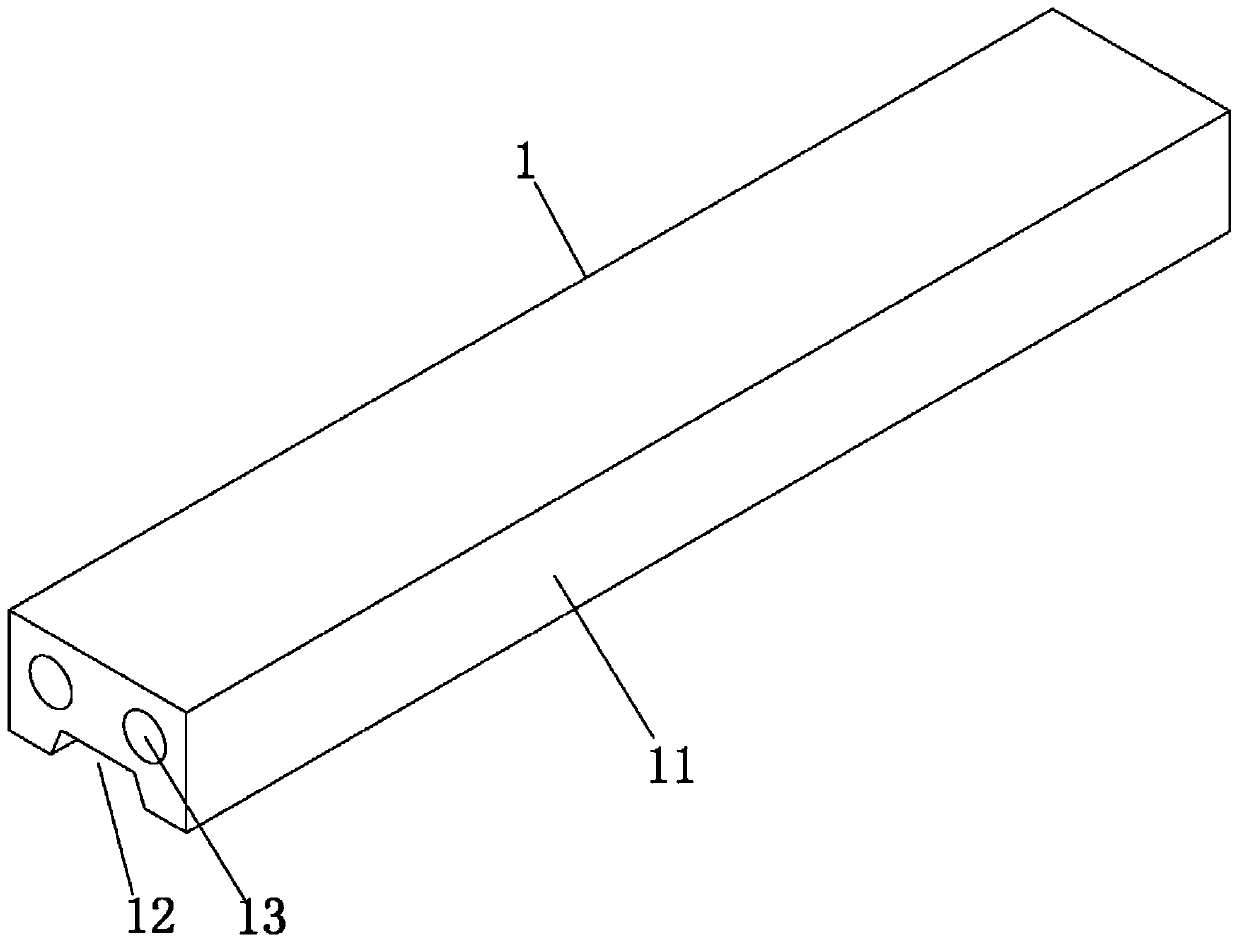

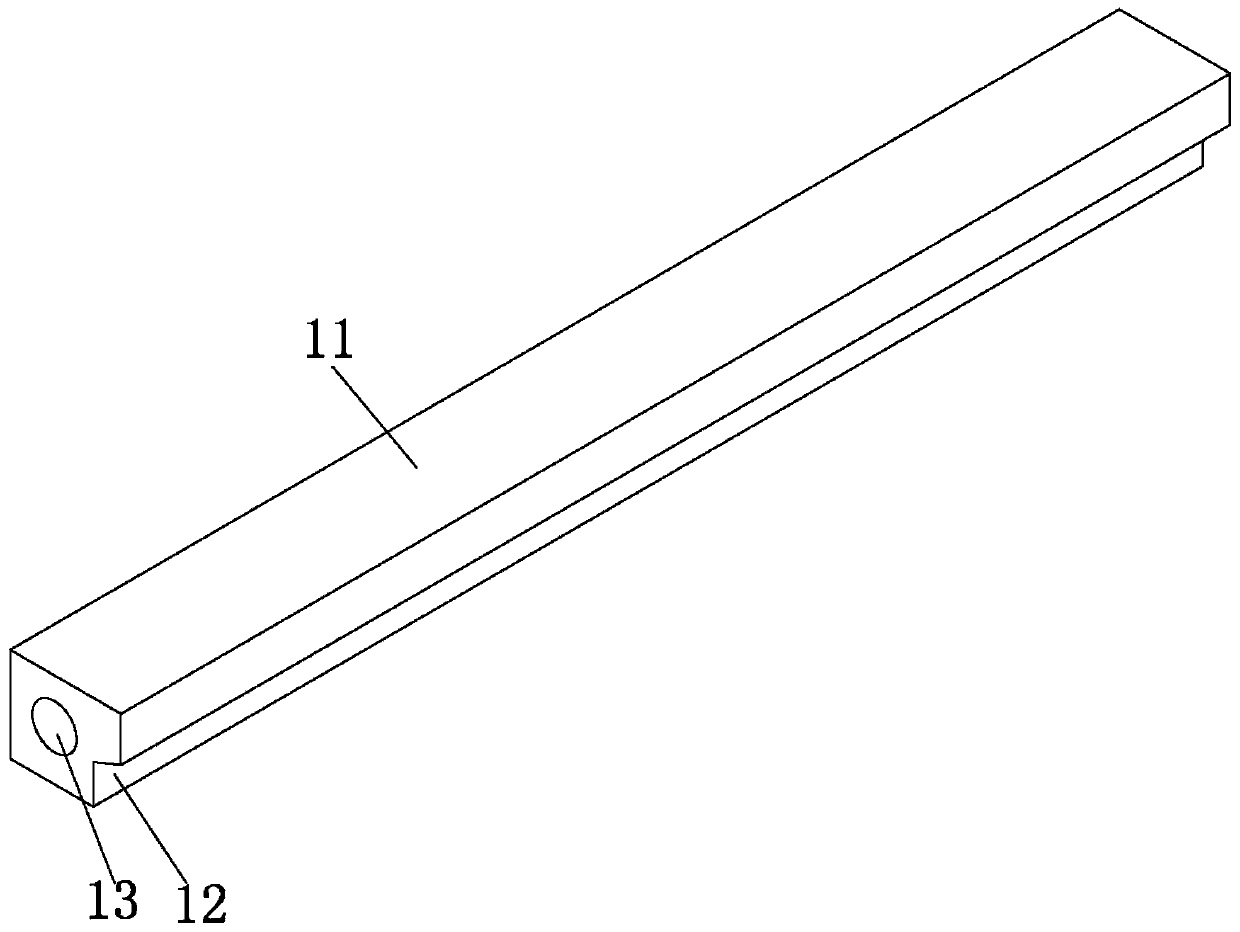

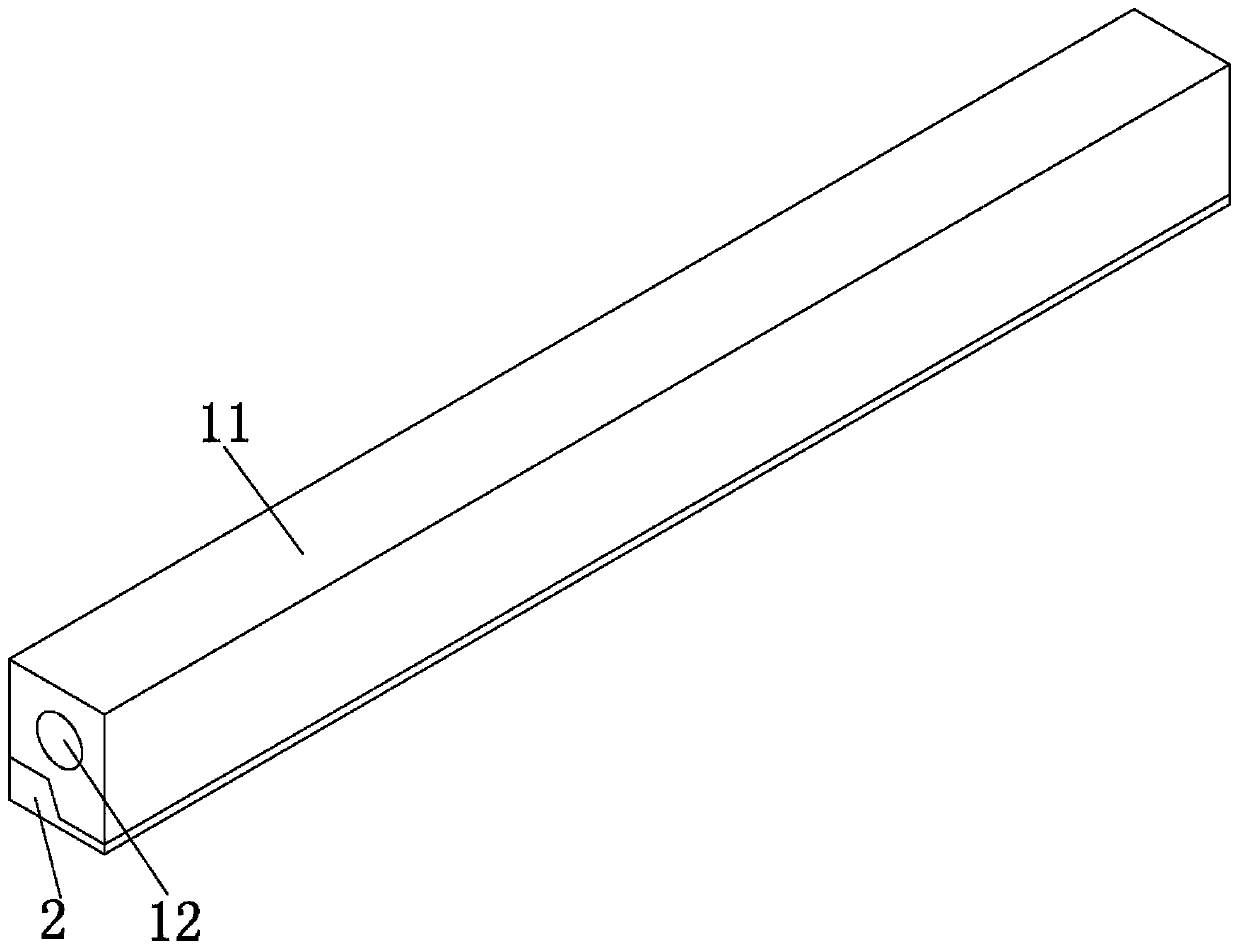

[0023] Please refer to the attached figure 1 to attach image 3 Shown, the present invention relates to a kind of construction method of prefabricated concrete guide wall, and it comprises following processing step:

[0024] 1), based on the design drawings, manufacture and process the prefabricated guide wall 1 in the factory, and perform pouring production according to a pair of mirrored guide walls. The prefabricated guide wall 1 after pouring includes a wall portion 11 , and a groove 12 is provided at the center of the bottom of the wall portion 11 . In this embodiment, the rebate 12 is trapezoidal. On the one hand, the integrity between the two can be strengthened by sitting to reduce the possibility of water seepage; It can reduce the possibility of internal water leakage.

[0025] Further, the prefabricated guide wall 1 is provided with several pipeline reserved holes 13 along its length direction, so that the pipelines can be arranged along the guide wall, thereby f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com