Hybrid-type stepping motor

A technology of stepping motor and stator yoke, which is applied to electrical components, electromechanical devices, etc., can solve problems such as difficulty in coil winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

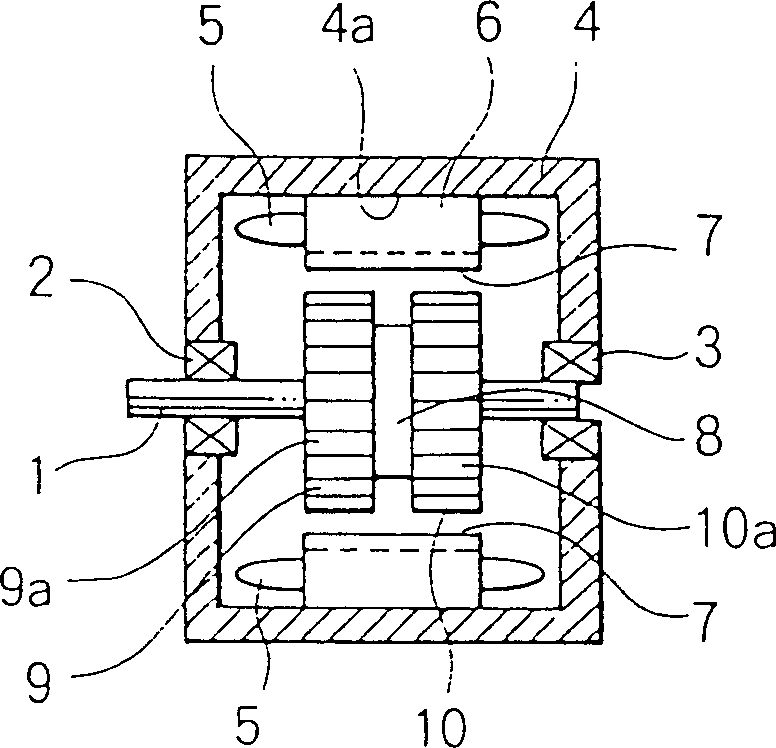

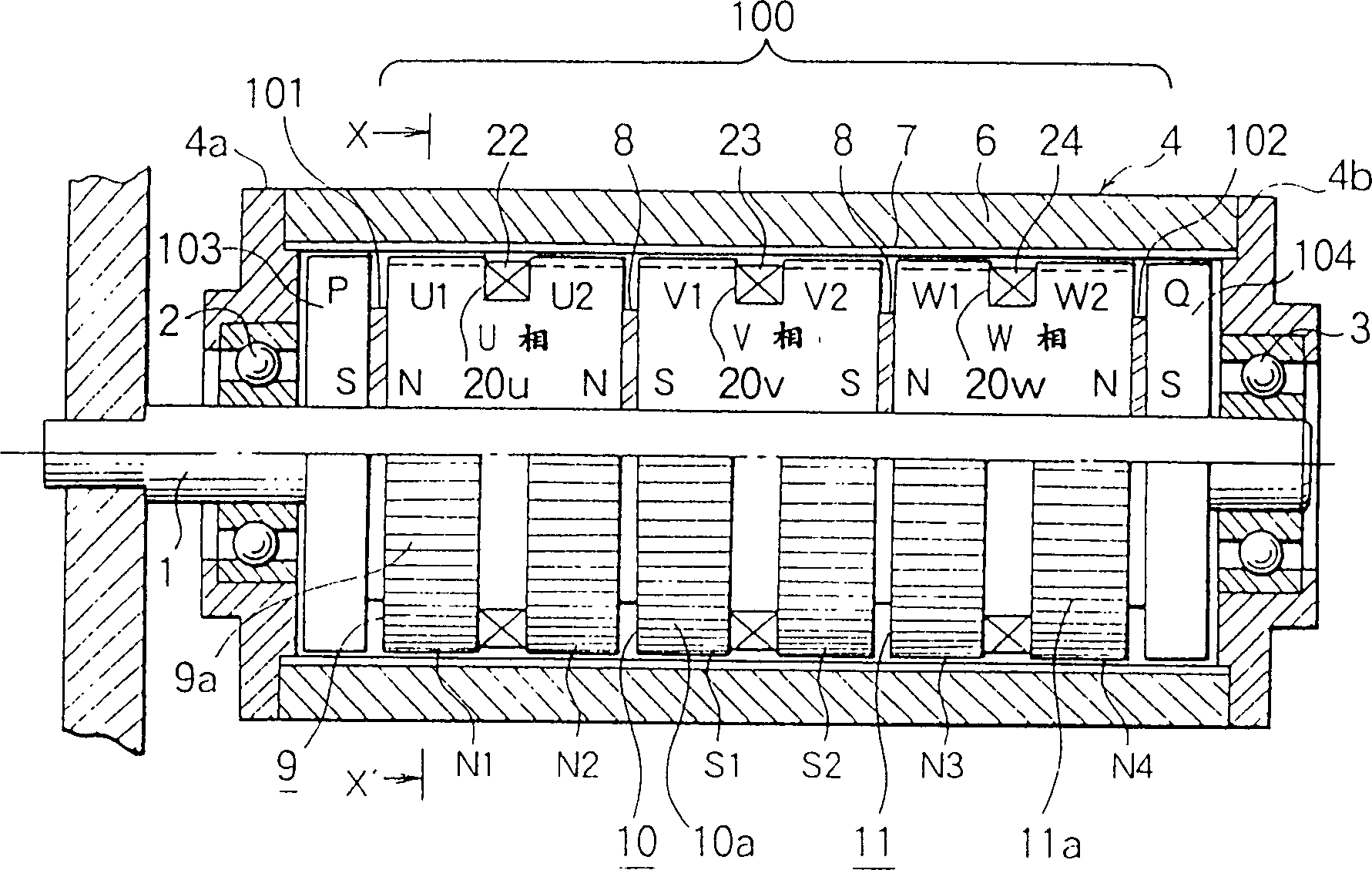

[0044] With reference to the accompanying drawings, the compound stepping motor of the present invention is now discussed. Parts identical or equivalent to those of the prior art are indicated with the same reference numerals.

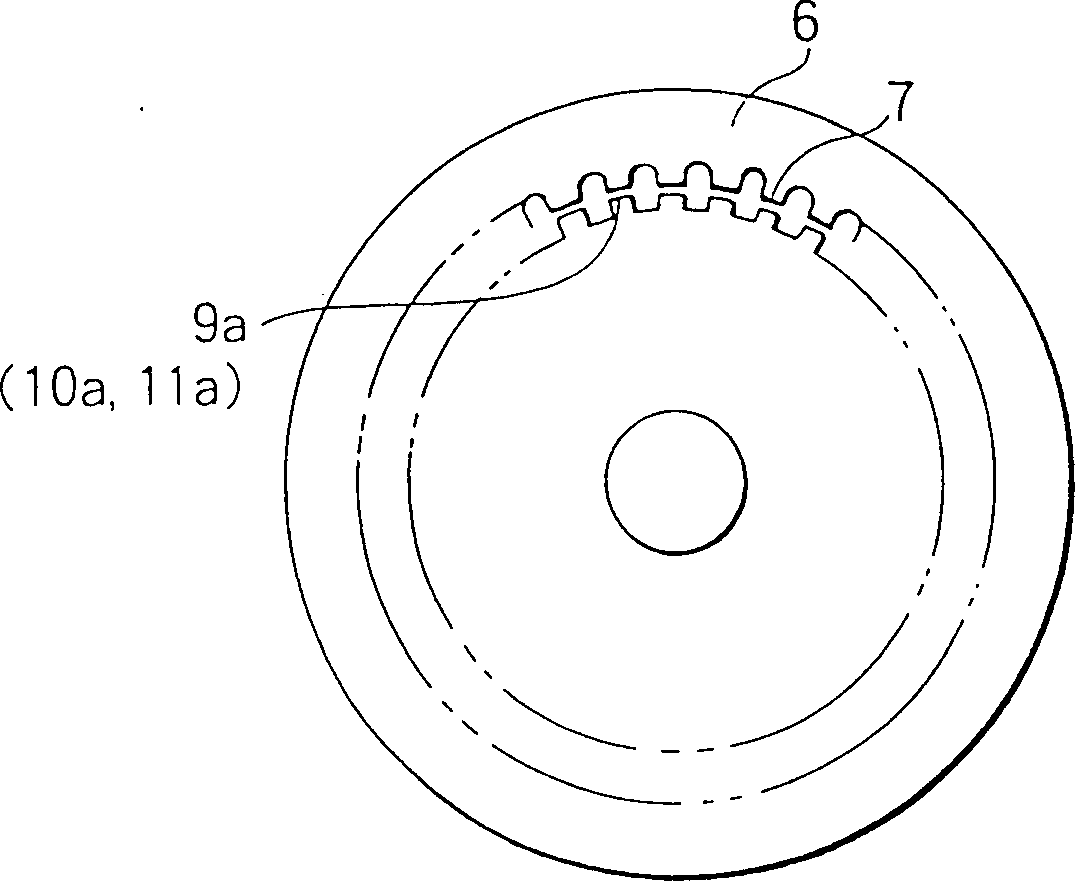

[0045] figure 2 A compound stepper motor with an outer rotor structure is shown. Reference numeral 1 is a fixed shaft made of non-magnetic material, on which a pair of bearings 2, 3 spaced apart from each other are housed. A rotor housing 4 composed of a front end cover 4 a , a rear end cover 4 b and a cylindrical rotor yoke 6 is rotatably supported on bearings 2 , 3 . A plurality of rotor teeth 7 are arranged on the inner circumference of the rotor yoke 6 of the rotor housing 4 .

[0046] The first, second and third annular stator yokes 9, 10, 11 together with the flat magnets 8 sandwiched therebetween are arranged side by side along the direction of the fixed axis on the fixed axis 1 to form a whole including the flat magnets 8. The circumferences ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com