Multi-constraint scheduling calculation method and device for aviation part machining automatic production line

An automated production line and aviation parts technology, applied in the field of aviation production, can solve problems such as slow calculation speed and inability to meet real-time calculation requirements, and achieve high practicability, reduce task delay time, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

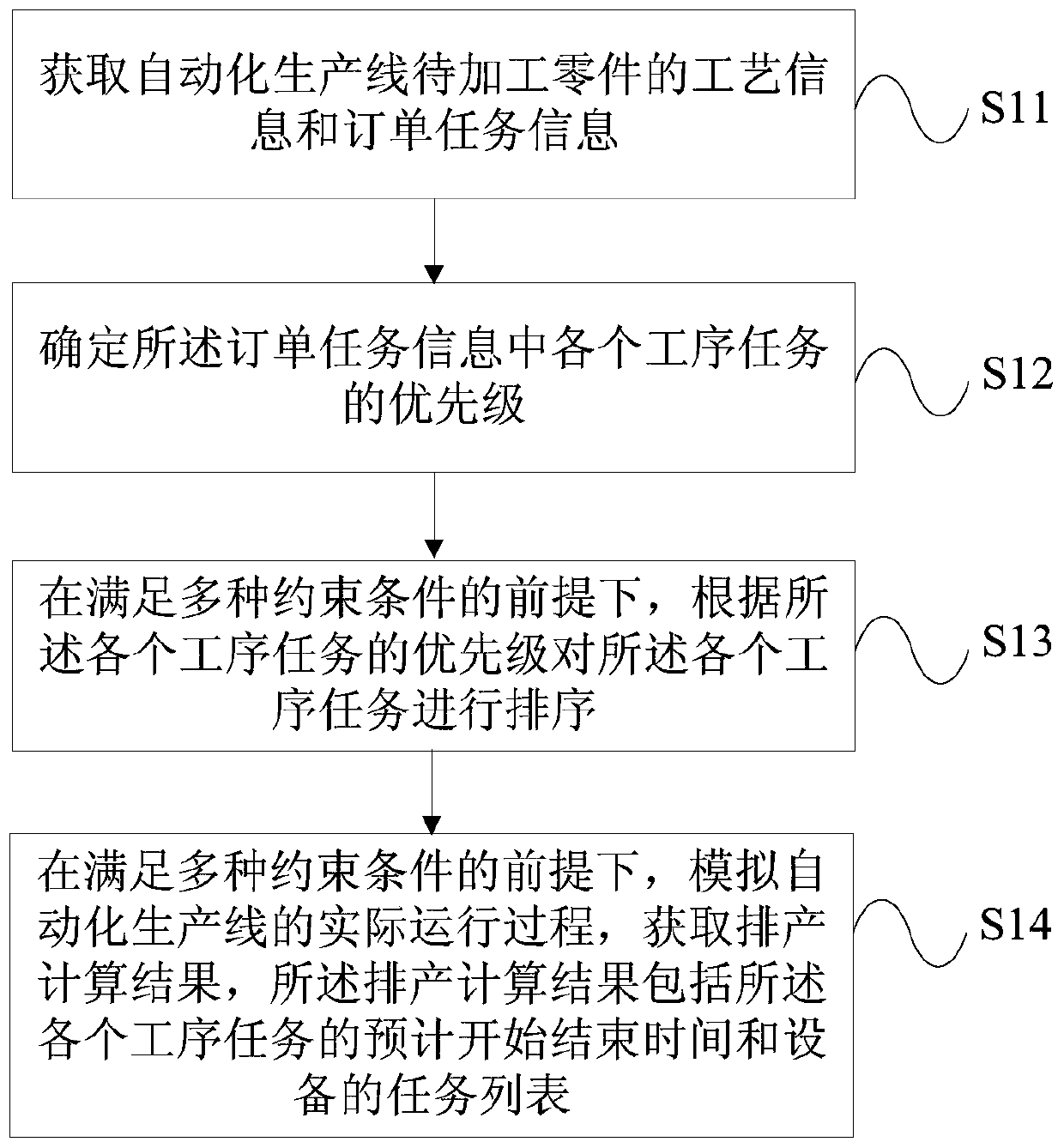

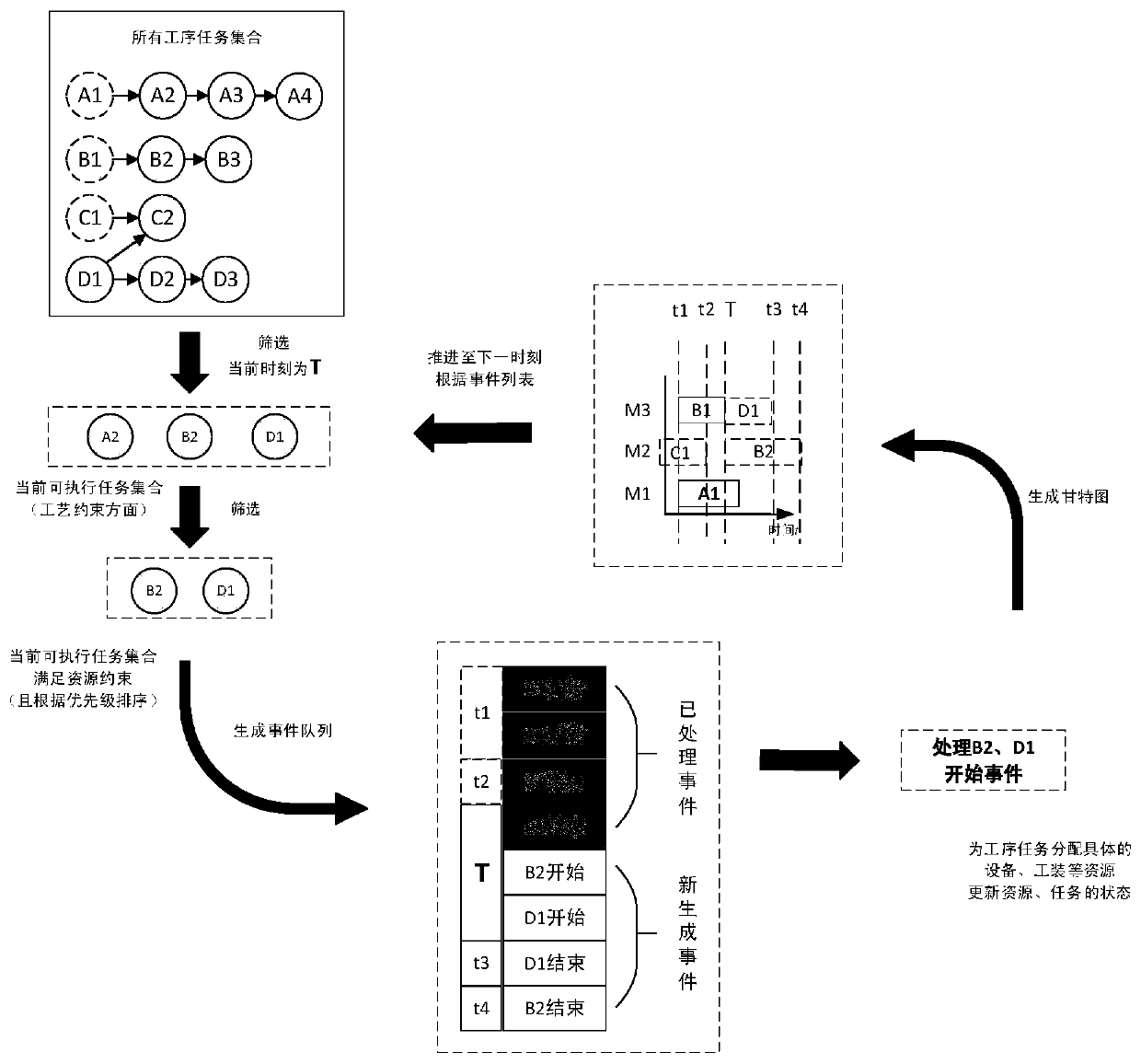

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

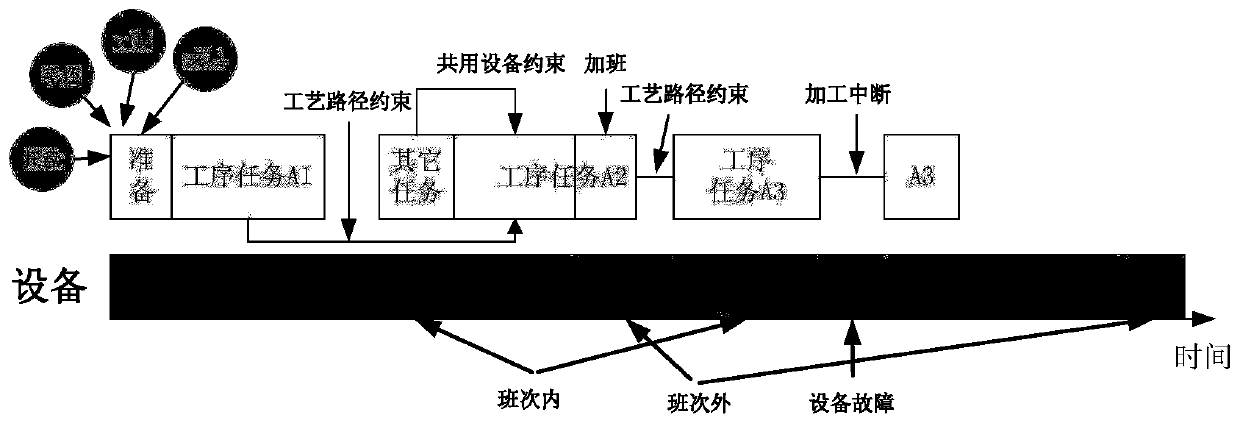

[0050] The aviation manufacturing industry is a typical multi-variety, small-batch discrete manufacturing industry. The corresponding automatic production line of aviation parts must integrate resource status information such as manpower, equipment, materials, etc. production constraints, the generated production job plan needs to have a high degree of reference and accuracy. The production scheduling calculation problem of the aviation parts automatic production line is a combinatorial optimization problem, which is one of the keys to the efficient operation of the production line. A reasonable production operation plan requires an effective production scheduling solution method.

[0051] Automated production lines put forward higher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com