Rail transit equipment manufacturing monitoring method, system and device and storage medium

A technology for equipment manufacturing and rail transit, applied in the fields of systems, monitoring methods for rail transit equipment manufacturing, devices, and storage media, can solve problems such as low work efficiency, time delays in urban rail transit engineering projects, and inconvenient information sharing and collaborative office work. , to achieve the effect of ensuring progress and quality, realizing information sharing, and promoting collaborative office

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For the step numbers in the following embodiments, it is only set for the convenience of illustration and description, and the order between the steps is not limited in any way. The execution order of each step in the embodiments can be adapted according to the understanding of those skilled in the art sexual adjustment.

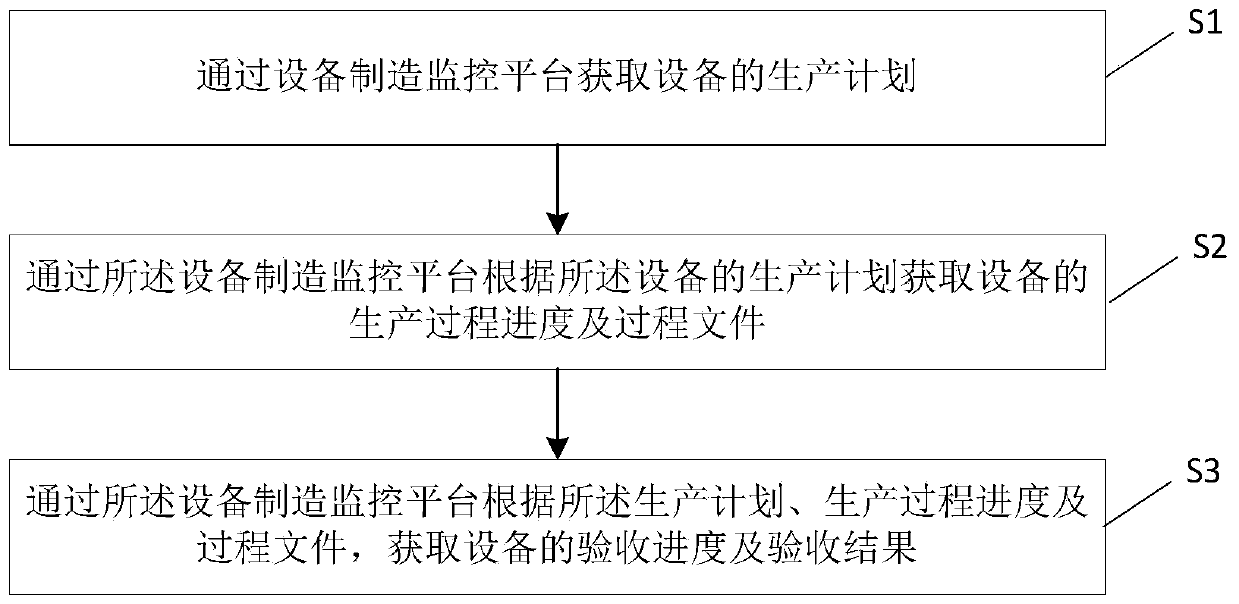

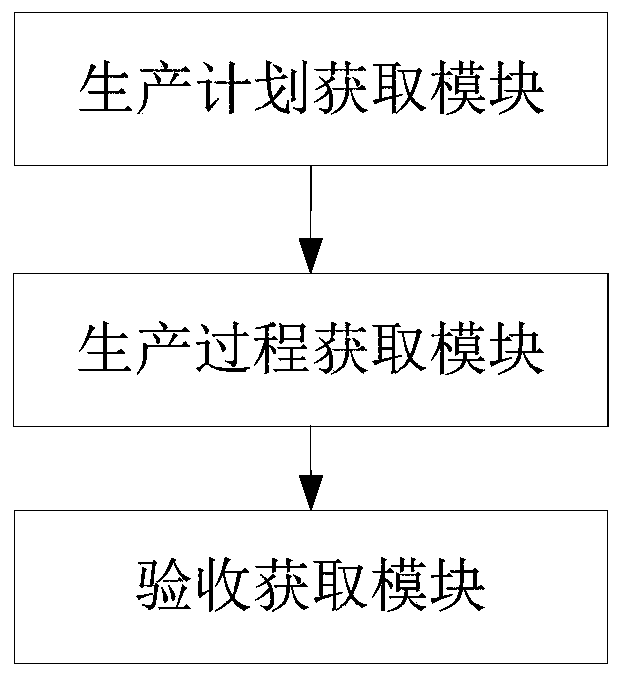

[0041] Such as figure 1 As shown, the embodiment of the present invention provides a monitoring method for rail transit equipment manufacturing, comprising the following steps:

[0042] S1. Obtain the production plan of the equipment through the equipment manufacturing monitoring platform;

[0043] S2. Obtain the production process progress and process documents of the equipment according to the production plan of the equipment through the equipment manufacturing monitoring platform;

[0044] S3. Obtain the accepta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com