Trench VDMOS device with integrated ESD protection and manufacturing method

A technology for ESD protection and devices, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as large substrate coupling noise, obvious parasitic effects, and large drain-source current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

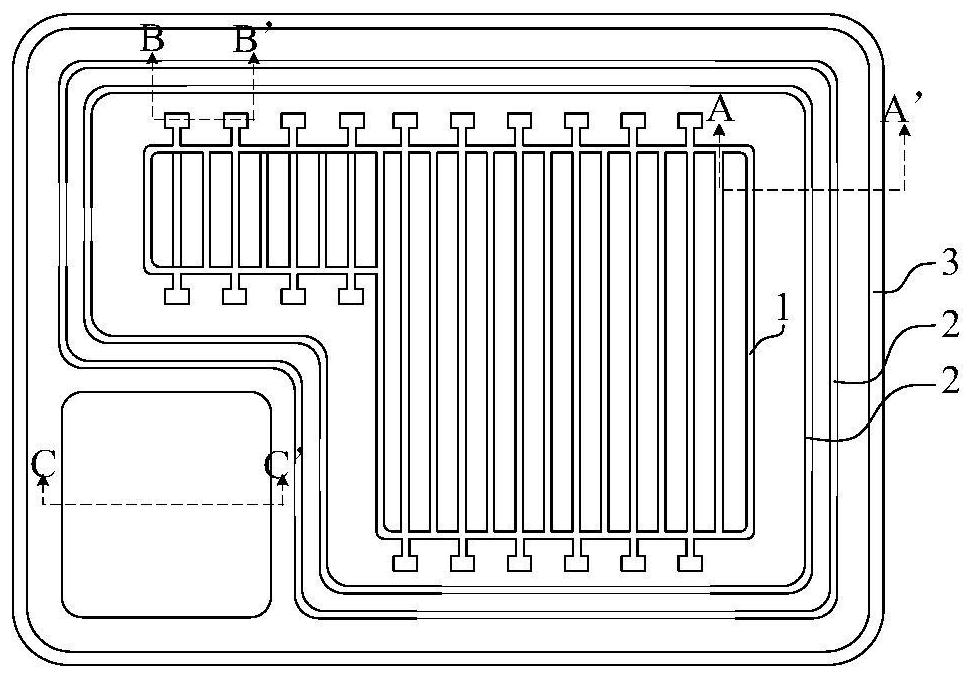

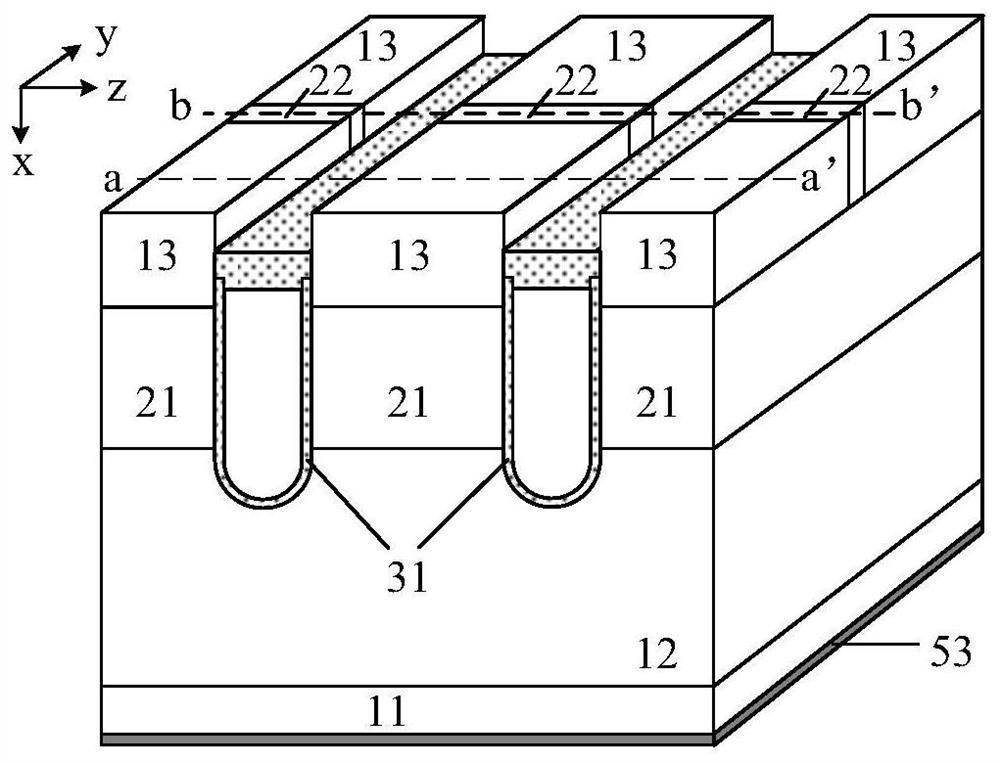

[0062] A Trench VDMOS device with integrated ESD protection, including a Trench VDMOS structure and an ESD protection structure;

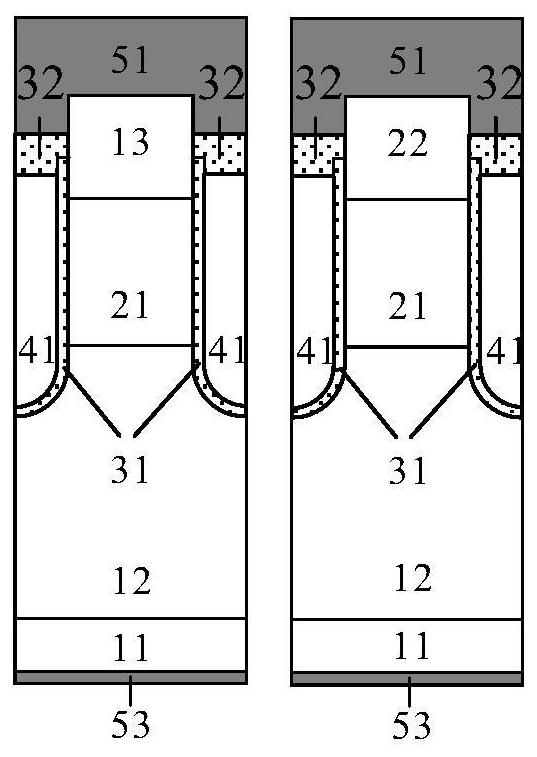

[0063] The Trench VDMOS structure includes a cell area and a terminal protection area, the cell area includes a plurality of cells with the same structure and sequentially connected, the cell area includes a first conductivity type substrate 11, and is located between the first conductivity type substrate 11 The drift region 12 of the first conductivity type on the top, the well region 21 of the second conductivity type located above the drift region 12 of the first conductivity type, the source contact region 13 of the first conductivity type located above the well region 21 of the second conductivity type and the second conductivity type The source contact region 22 of the second conductivity type, the source metal 51 is located above the pre-metal dielectric 32 and is in contact with the source contact region 22 of the second conductivity type an...

Embodiment 2

[0090] Figure 7 The Trench VDMOS sectional view provided in Embodiment 2 is different from Embodiment 1 in that the source contact region 13 of the first conductivity type is arranged above the source contact region 13 of the second conductivity type and the source contact region 22 of the second conductivity type. .

Embodiment 3

[0092] Figure 8 The difference between the Trench VDMOS sectional view provided in Embodiment 3 and Embodiment 2 is that a metal silicide 00 is disposed above the source contact region 13 of the first conductivity type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com