Superjunction device and manufacturing method thereof

A super junction and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as long manufacturing cycle, increased process cost, and severe reverse recovery fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

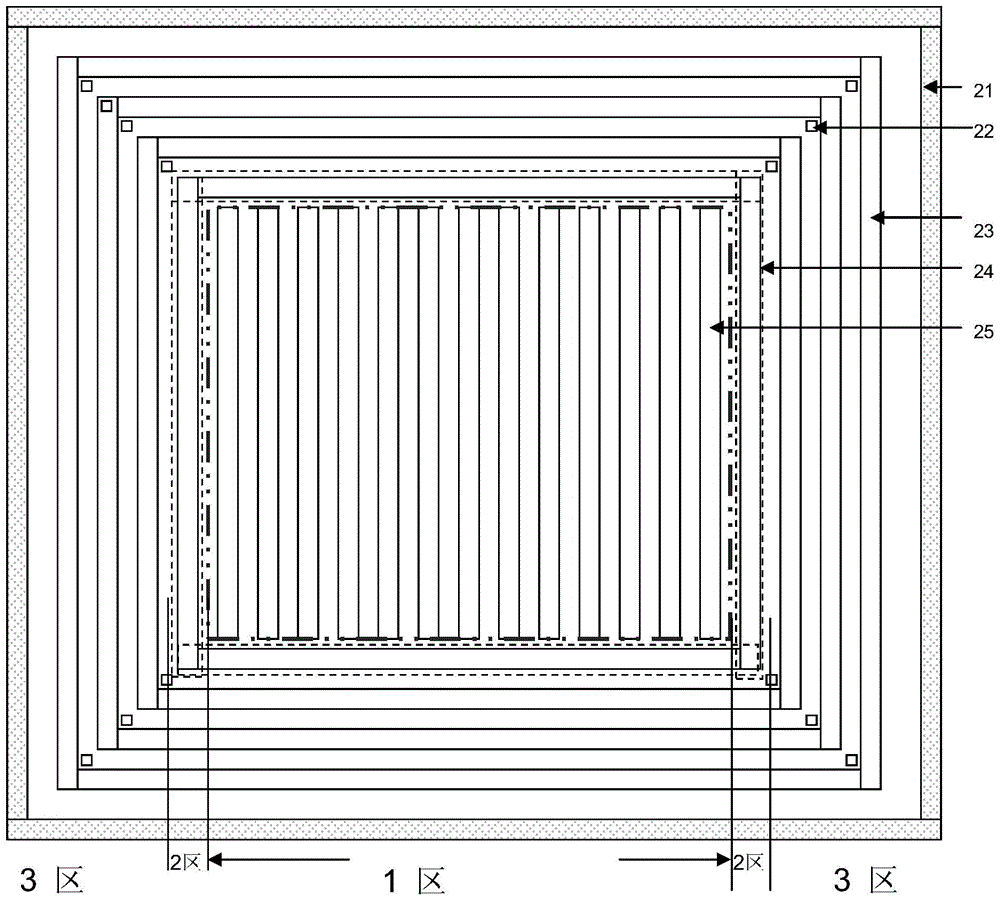

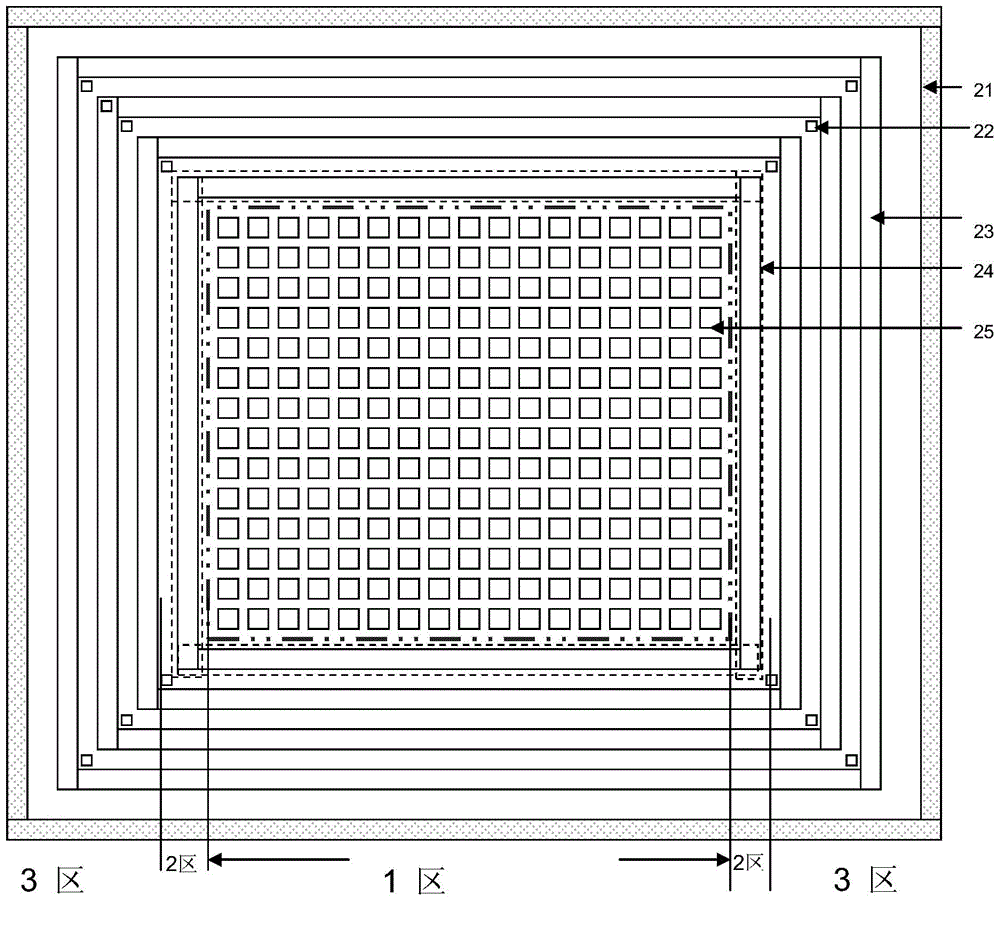

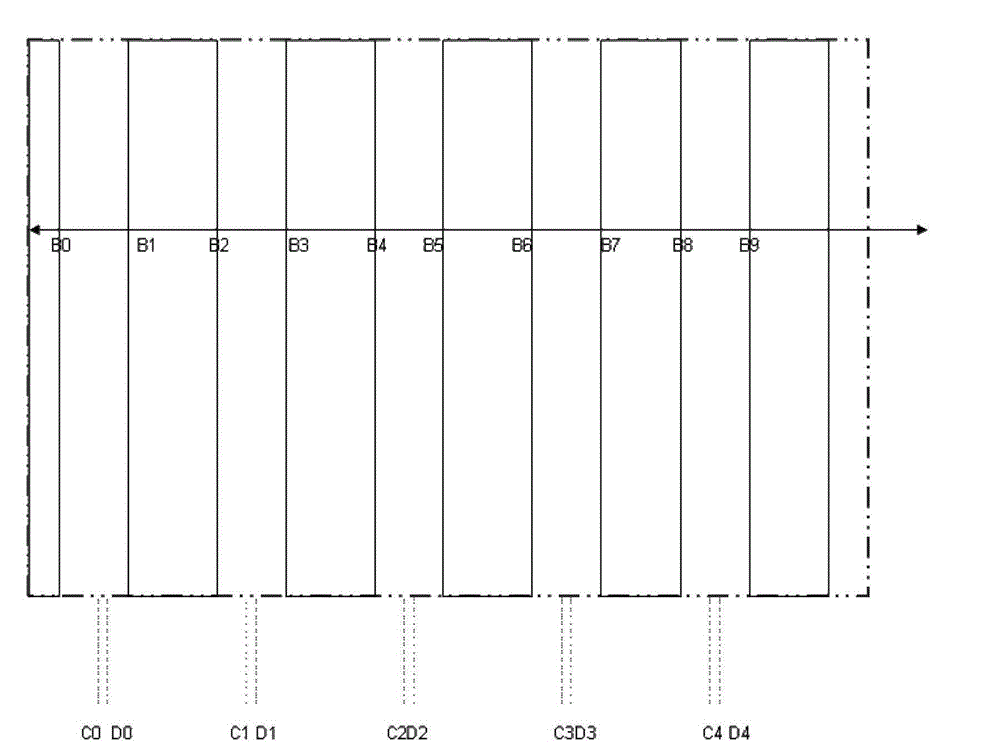

[0120] Such as figure 1 Shown is the top view of the existing super junction device Figure 1 . In the top view, the embodiment of the present invention can be divided into zone 1, zone 2 and zone 3. Region 1 is the middle region of the super junction device, which is the current flow region, and the current flow region includes alternately arranged P-type regions 25 and N-type regions, and the P-type regions 25 are also P-type regions formed in the current flow region. The N-type thin layer, the N-type region is also the N-type thin layer formed in the current flow region; in the current flow region, the current will pass through the N-type region from the source to the drain through the channel, and the The P-type region 25 is in the reverse cut-off state and forms a depletion region together with the N-type region to withstand voltage. Zones 2 and 3 are the terminal protection structure regions of the super junction device. The terminal protection structure does not prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com