Low-resistance device with equipotential floating grooves and manufacturing method of low-resistance device

A floating and equipotential technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as larger than on-resistance, and achieve the effects of high withstand voltage, increased withstand voltage, and large average electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

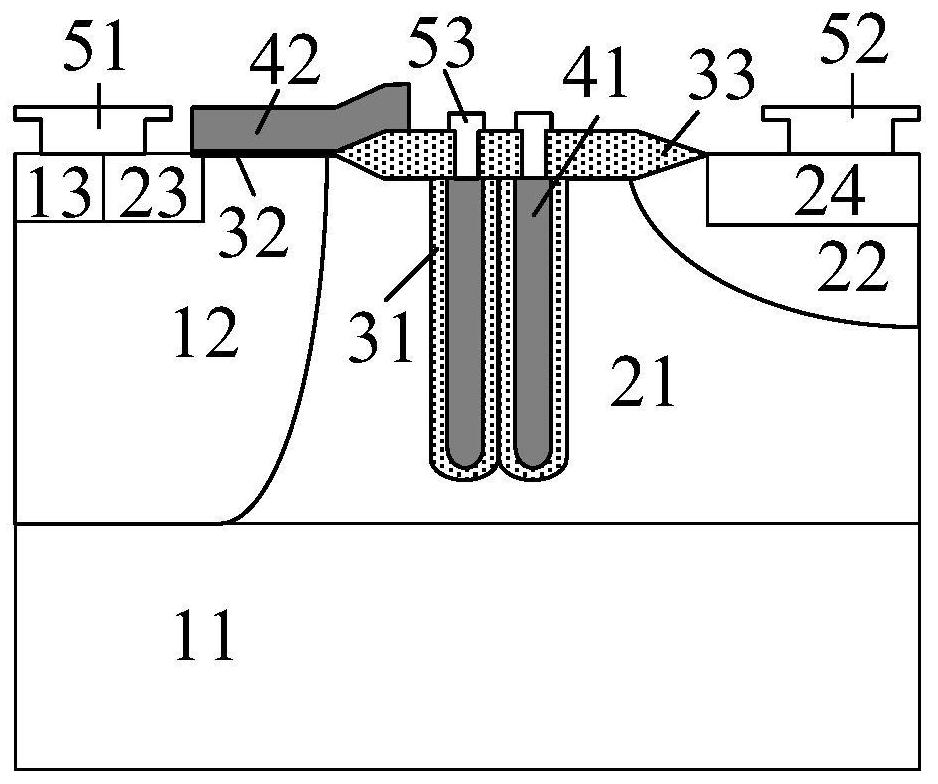

[0040] A kind of low-resistance device with equipotential floating slot described in embodiment 1, such as figure 1 shown, including:

[0041] First conductivity type semiconductor substrate 11, first conductivity type well region 12, first conductivity type source heavily doped region 13, second conductivity type drift region 21, second conductivity type well region 22, second conductivity type source Terminal heavily doped region 23, second conductivity type drain terminal heavily doped region 24, first dielectric oxide layer 31, second dielectric oxide layer 32, third dielectric oxide layer 33, floating field plate polysilicon electrode 41, control gate Polysilicon electrode 42, source metal 51, drain metal 52, metal strip 53;

[0042]Wherein, the drift region 21 of the second conductivity type is located above the semiconductor substrate 11 of the first conductivity type, the well region 12 of the first conductivity type is located on the left side of the drift region 21 ...

Embodiment 2

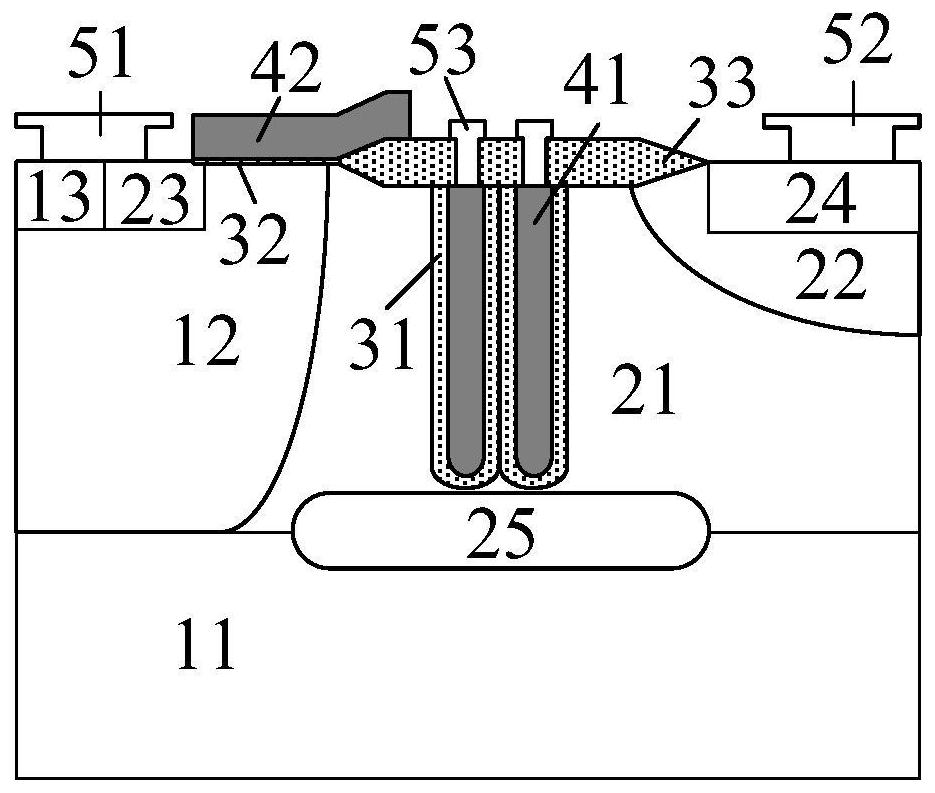

[0064] Such as figure 2 As shown, it is a schematic diagram of the structure of a low-resistance device with an equipotential floating slot in Example 2. The difference between this example and the structure of Example 1 is that the bottom of the vertical floating field plate is formed by ion implantation at the bottom of the slot The buried layer 25 of the second conductivity type. In this example, the buried layer 25 of the second conductivity type introduces a low-resistance conductive path at the bottom of the groove to further reduce the device resistance and increase the device current. Its working principle is basically the same as that of Embodiment 1.

Embodiment 3

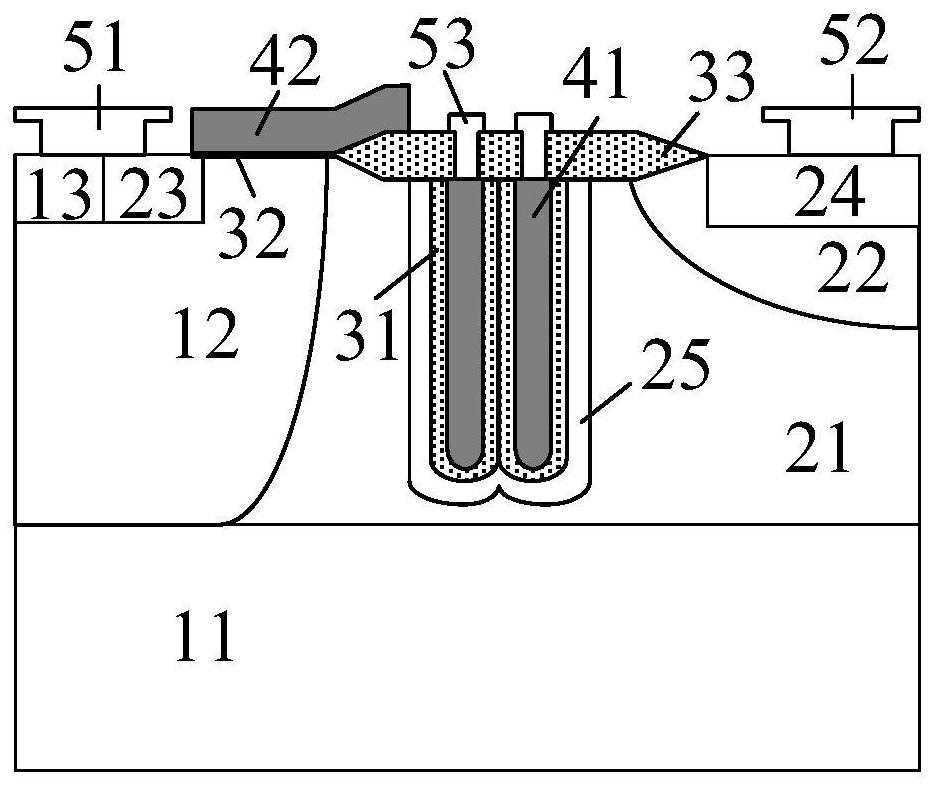

[0066] Such as image 3 As shown, it is a schematic diagram of the structure of a low-resistance device with an equipotential floating slot in Example 3. The difference between this example and the structure of Example 1 is that the periphery of the vertical floating field plate is formed by oblique implantation of the slot wall The second conductivity type doped strip 25 surrounding the vertical field plate structure, in this example, the second conductivity type doped strip 25 introduces a low-resistance conductive path around the vertical floating field plate, further reduces the device resistance, improves the device current, and its working The principle is basically the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com