Resistive random access memory and preparation method thereof

A resistive memory, resistive technology, used in electrical components and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

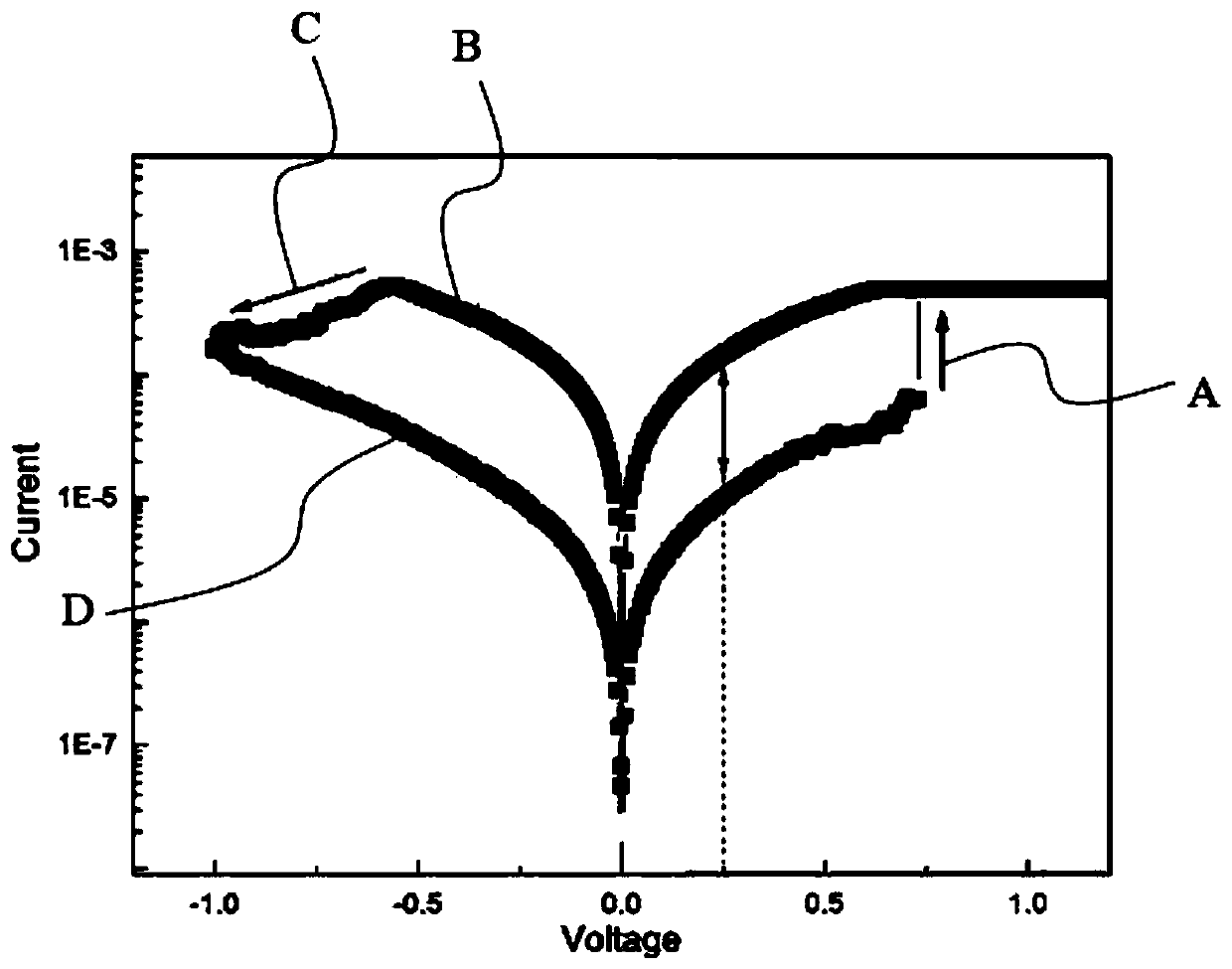

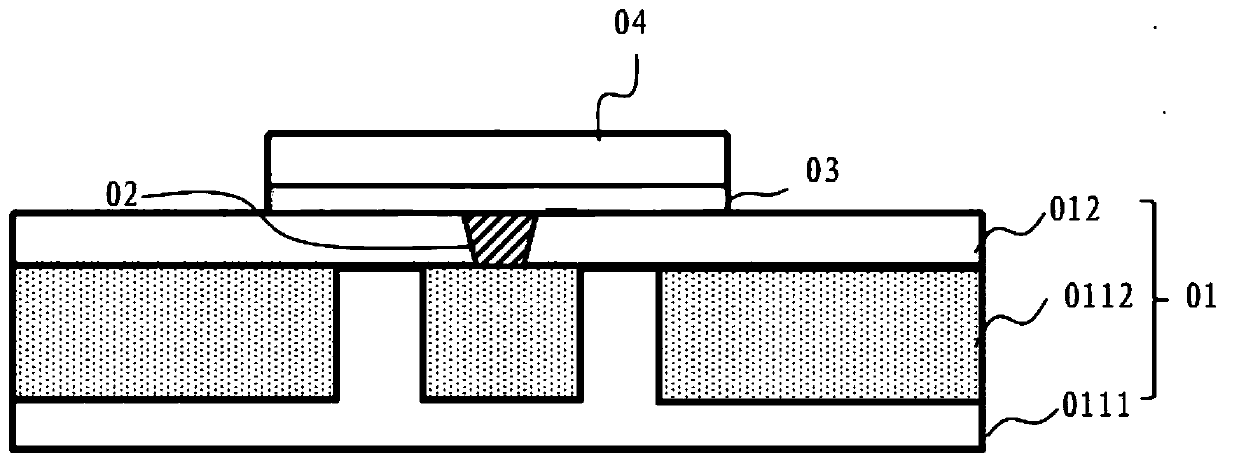

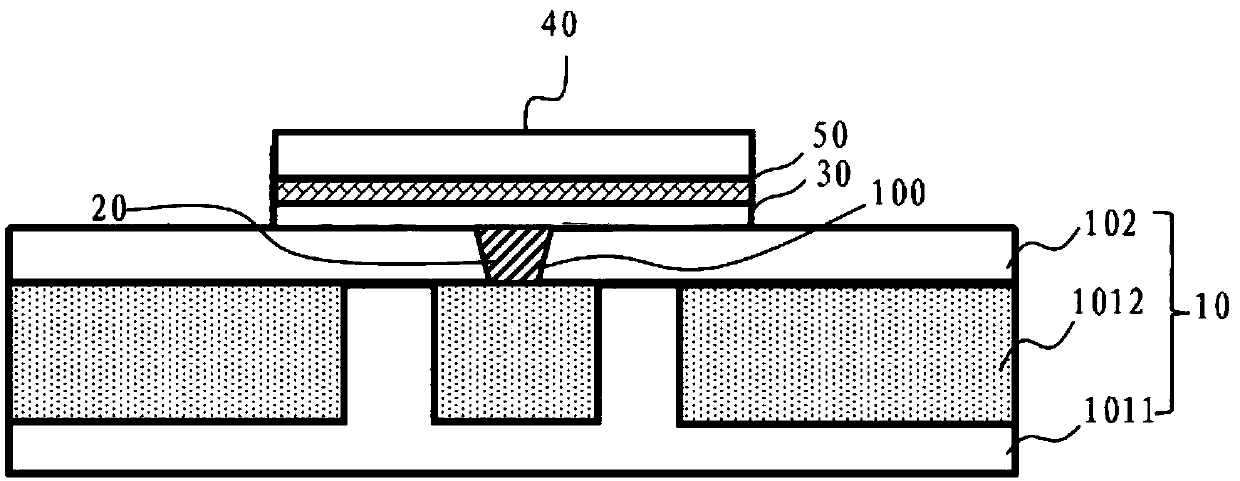

[0031] With the rapid development of modern information technology, people's demand for non-volatile memory with faster speed, higher capacity and lower power consumption is increasing. As a research hotspot of next-generation memory, resistive memory has strong application potential and is considered to be the memory with the most commercial value. The working principle of the resistive variable memory is that the resistive material realizes high-low resistance state transition under electric drive, thereby realizing data storage. like figure 1 It is the high-low resistance transition I-V curve of common resistive memory, A is the transition from high resistance state to low resistance state, B is the low resistance state, C is the transition from low resistance state to high resistance state, and D is the high resistance state. The common resistive memory structure is to grow a layer of resistive material between the upper and lower electrodes. This kind of resistive memory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com