Waterproof connector and manufacturing method thereof

A technology of waterproof connector and manufacturing method, which is applied in connection, manufacture of contact box/base, dust-proof/splash-proof/leak-proof/waterproof/fireproof connection, etc., capable of solving assembly gaps and poor waterproof performance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

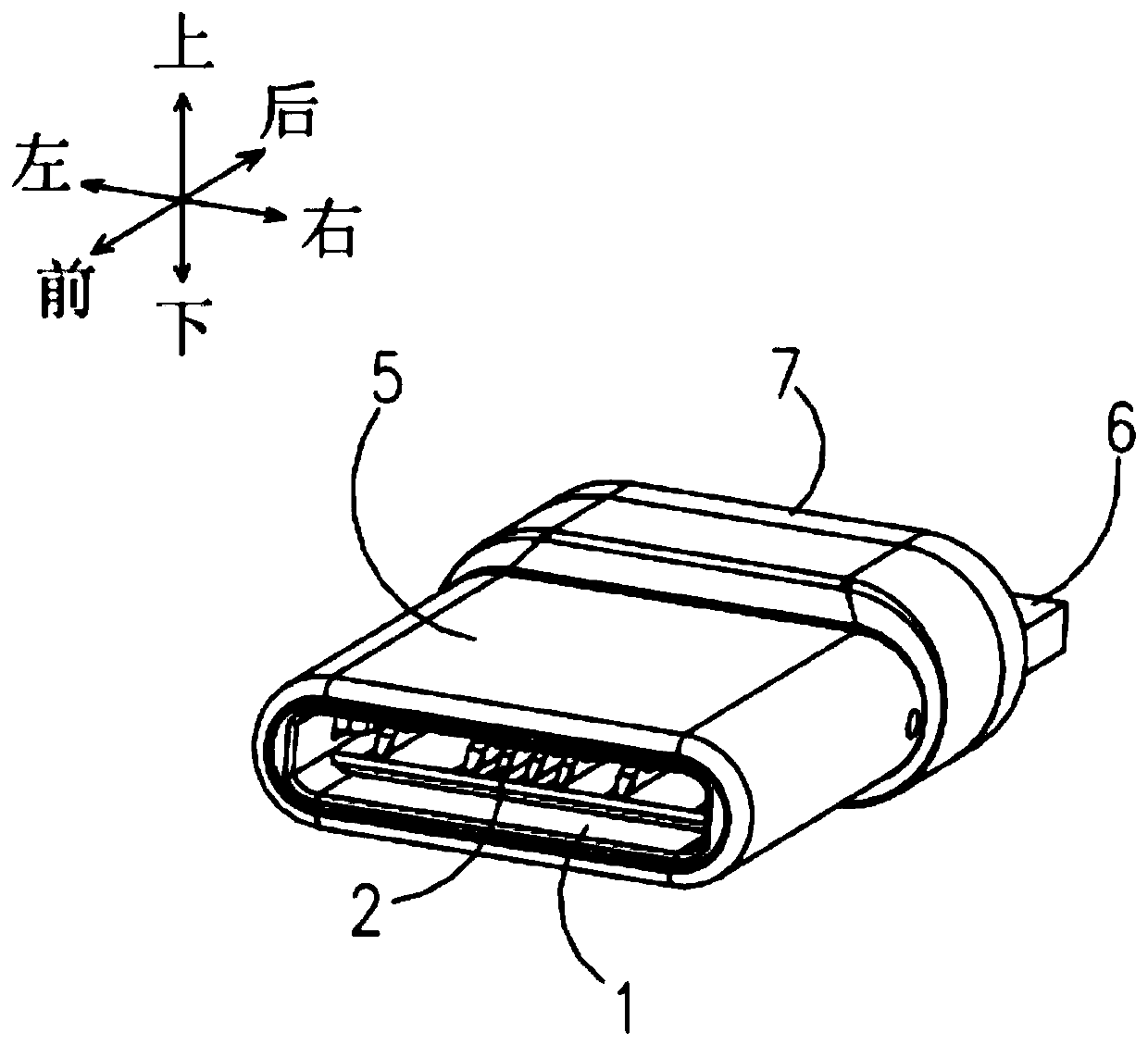

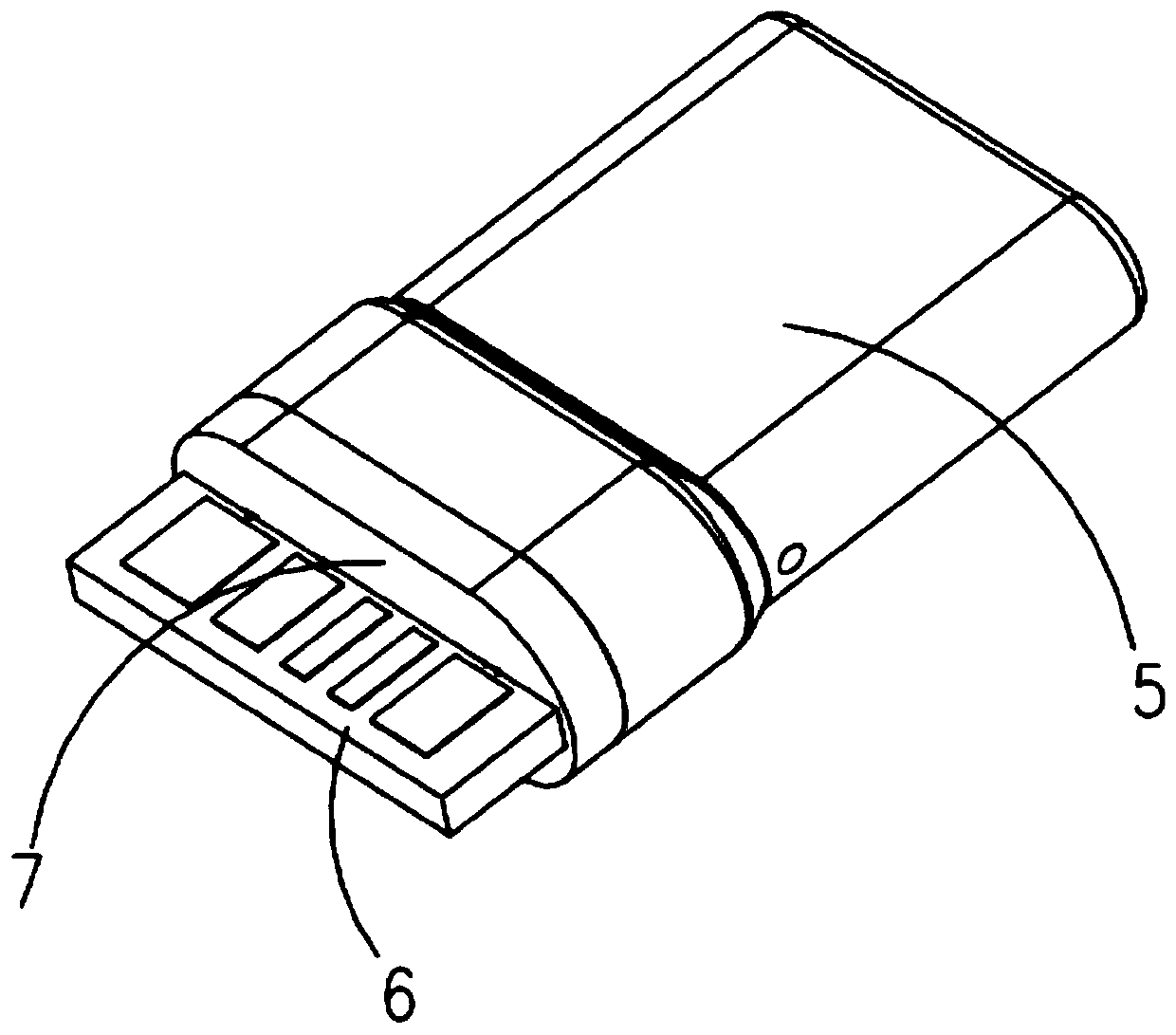

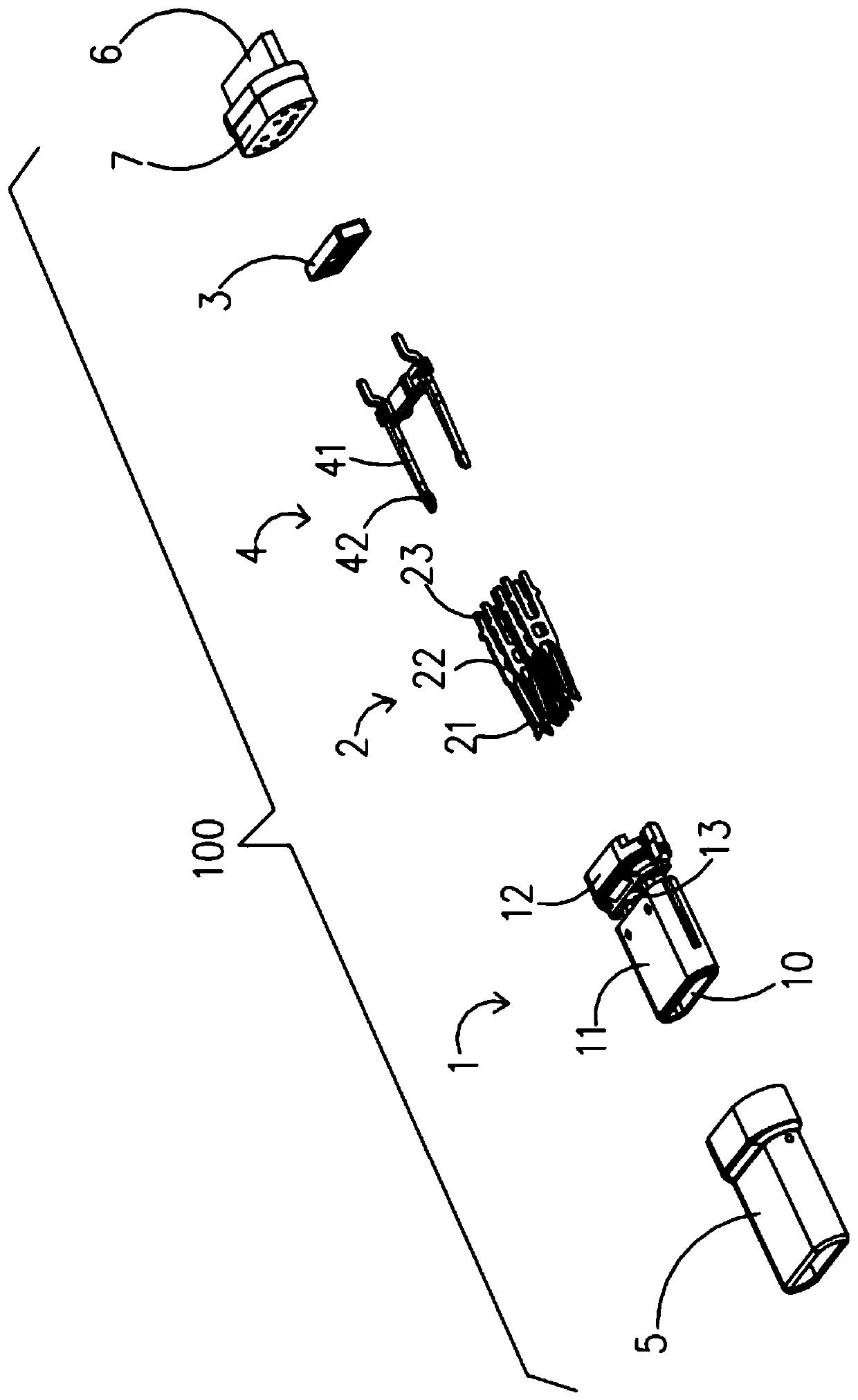

[0022] Please refer to Figure 1 to Figure 6 , a waterproof connector, including an insulating body 1 and a plurality of conductive terminals 2. The insulating body 1 is integrally injection molded and has a front end 11 forming a docking space 10 and a rear end 12 integrally extending backward from the front end 11 and forming a plurality of terminal slots 14 inside. The terminal slots 14 are connected to the docking space 10 connectivity. The insulating body 1 is recessed from the outer surface to form a receiving groove 13 communicating with the terminal groove 14 . The conductive terminal 2 is inserted and assembled into the insulating body 1 from the back to the front, the conductive terminal 2 has a contact portion 21, a holding portion 22 and a tail portion 23, the contact portion 21 extends forward into the docking space 10, The tail portion 23 extends backwards out of the insulating body 1 , and an insulating block 3 is formed in the accommodating groove 13 to hold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com