Ordered porous array built by sliver and tantalum composite material as well as preparation method thereof

A technology of composite materials and porous arrays, applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of limited adsorption, separation, catalysis, sensing applications, complex preparation process, and inconvenient mass preparation , to achieve the effects of easy-to-obtain raw materials, simple operation, good catalytic and optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing an ordered porous array constructed of a silver-tantalum composite material, comprising the following steps:

[0035] 1) Single crystal silicon wafer is selected as the substrate, and the single crystal silicon wafer substrate is selected from Si(100), Si(111), SiO 2 Sheet (Si / SiO 2 , the thickness of the oxide layer is 300nm) or quartz glass. And carry out pretreatment before coating; specifically, use deionized water, absolute ethanol, and acetone to ultrasonically clean the surface of the single crystal silicon wafer for 10-20 minutes.

[0036] 2) Put the cleaned single crystal silicon substrate into the magnetron sputtering coating equipment to prepare the chromium primer layer, specifically using Ar gas or nitrogen as the sputtering atmosphere, under the condition of applying a voltage of 60V to the substrate, using Magnetron sputtering is performed on the chromium target by radio frequency, and the radio frequency fr...

Embodiment 1

[0043] 1) Cleaning: immerse the Si(100) substrate in ethanol and acetone solution for 10 minutes, take it out and soak it in deionized water for 5 minutes, then take it out, dry it with high-purity nitrogen, and then quickly put it into the magnetron sputtering coating equipment middle.

[0044] 2) Chromium primer preparation: prepare the chromium primer on the clean single crystal silicon surface, use Ar gas as the sputtering atmosphere, apply a voltage of 60V, and use radio frequency to carry out magnetron sputtering on the chromium target, the radio frequency frequency is 250kHz; the chromium film The thickness is 100nm.

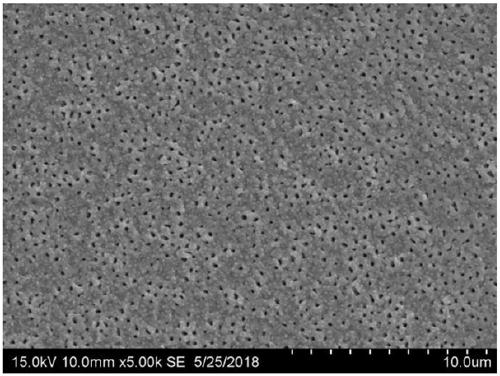

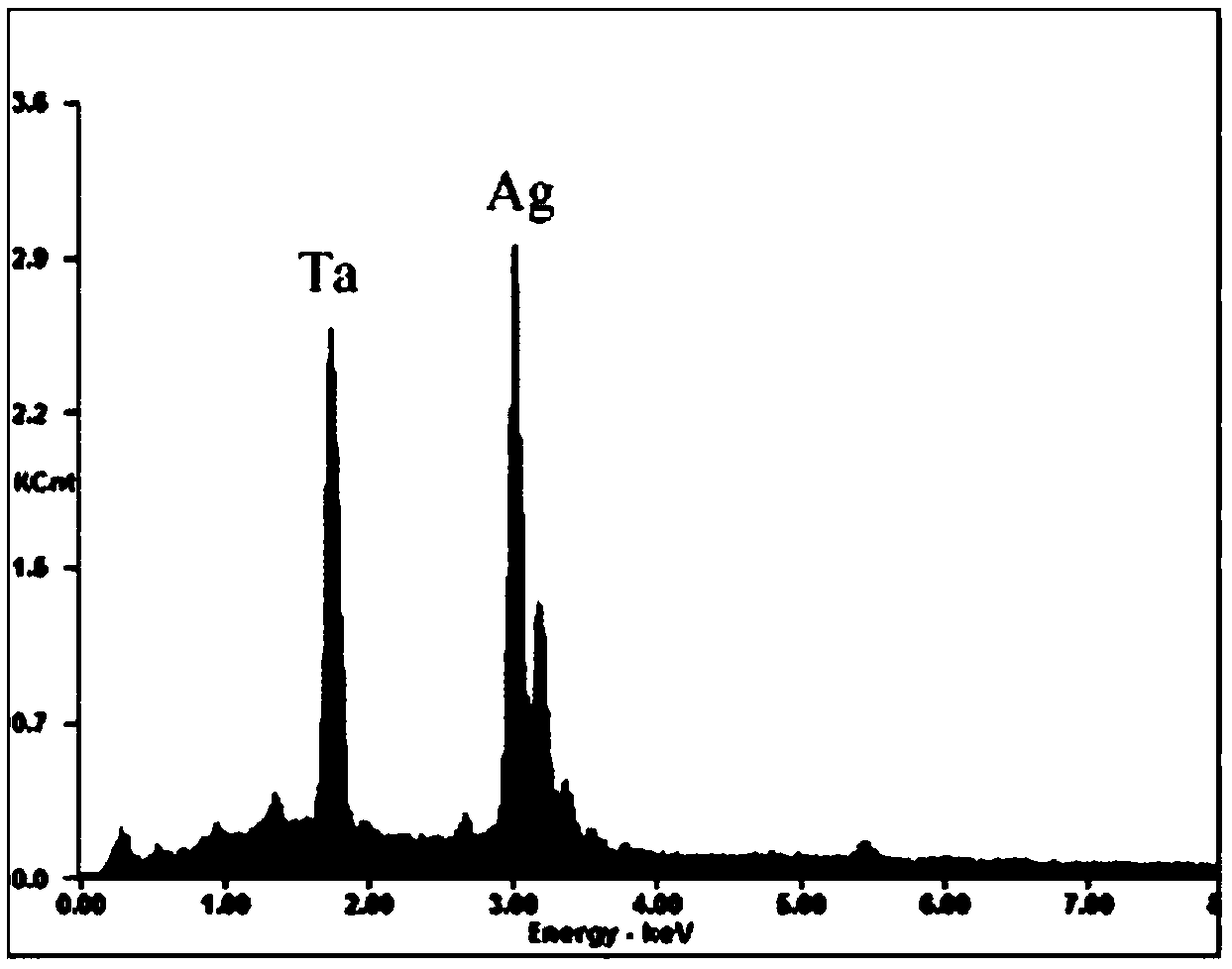

[0045]3) Silver and tantalum deposition: After the preparation of the chromium base layer, co-sputtering of silver and tantalum elements is carried out, in which the applied voltage is 60V, the current of the silver target is 5A, the current of the tantalum target is 1.8A, and the deposition time is 25min. On the surface of the single crystal silicon sub...

Embodiment 2

[0050] 1) Cleaning: immerse the Si(111) substrate in ethanol and acetone solution for 10 minutes, take it out and soak it in deionized water for 5 minutes, then take it out, dry it with high-purity nitrogen, and then quickly put it into the magnetron sputtering coating equipment .

[0051] 2) Chromium primer preparation: prepare chromium primer on the clean single crystal silicon surface, use nitrogen as the sputtering atmosphere, apply 60V voltage, and use radio frequency to perform magnetron sputtering on the chromium target with a radio frequency frequency of 250kHz; the thickness of the chromium film 100-500nm.

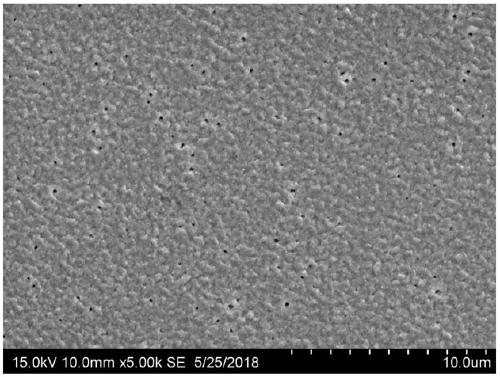

[0052] 3) Silver and tantalum deposition: After the preparation of the chromium base layer, co-sputtering of silver and tantalum elements is carried out, in which the applied voltage is 60V, the current of the silver target is 5A, the current of the tantalum target is 1A, and the deposition time is 25min. On the surface of the crystalline silicon substrate, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com